BDR-620

Second: Dismount the front plastic cover so that you can see the belt and disc drive pulley (Pict.11). (Marking (1) a (2) in pictures 10 and 11 are the

same and belong to the same cable.)

1) Tighten the belt by unscrewing the bolt

55

(1) in Pict.10 for approximately 1 mm in the direction of the arrow (away from the frame) and

repeat the check according to b). Continue tightening until condition b) is met and at the same time the belt transmission grip

56

stops while

wheel drive clutch lever is loose. If the bolt (1) cannot be unscrewed any further, screw it in completely against the direction of the arrow and

hook the spring at the end of the cable into a further opening in the pulley arm. Repeat tightening the belt until condition b) is met.

Check the automatic brake function after every adjustment!

2.5.4.1.1 V-belt exchange

Exchange the V-belt with a new one

57

every time you see cracks or breaks in its surface, or when it is so deteriorated that it cannot be tightened with

the tightening pulleys. Exact instructions for belt exchange are not included here, as their contents exceed the limitations of this manual. When exchanging

the belt, follow Pict.13. Follow belt track around all guide elements!

Seek authorised service in case you lack appropriate manual skills.

2.5.4.2 Brake function control and adjustment

Check the automatic brake function after every 10 hours of use. (Current control can be done during operation.) Every time you release the

disk drive clutch lever, the automatic brake must stop the disc within 5 sec.

Do not continue working with the cutter unless you remove the automatic brake defect.

Seek authorised service in case you lack appropriate manual skills.

In case the brake does not stop the cutting disc in the given time span, it is necessary to adjust the brake cable (2) Pict.10 a 11. . Adjusting screw,

which tightens the brake cable (2) to the cutter frame Pict.10, needs to be screwed in against the direction of the arrow (towards the frame), so that the

axial clearance of the brake cable in the adjusting screw is 1 mm. Check the automatic brake function. If complete tightening the screw (2) does not offer

adequate brake effect, tighten the adjusting screw of the brake cable on the handlebars so that the axial clearance of the brake cable in the adjusting screw

is 1 mm. Check the automatic brake function

58

.

If, after the adjustment

59

, the brake does not work properly, contact an authorised service center.

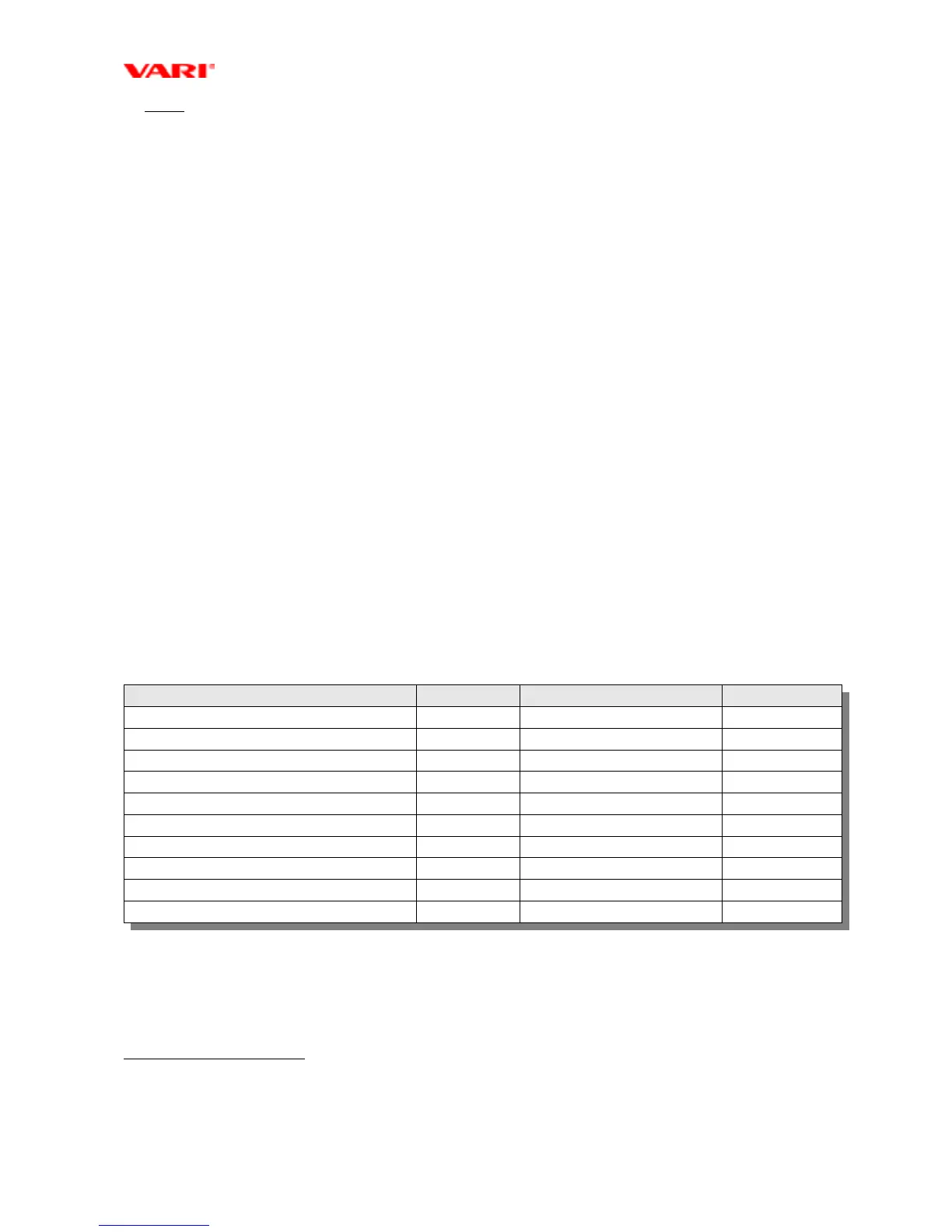

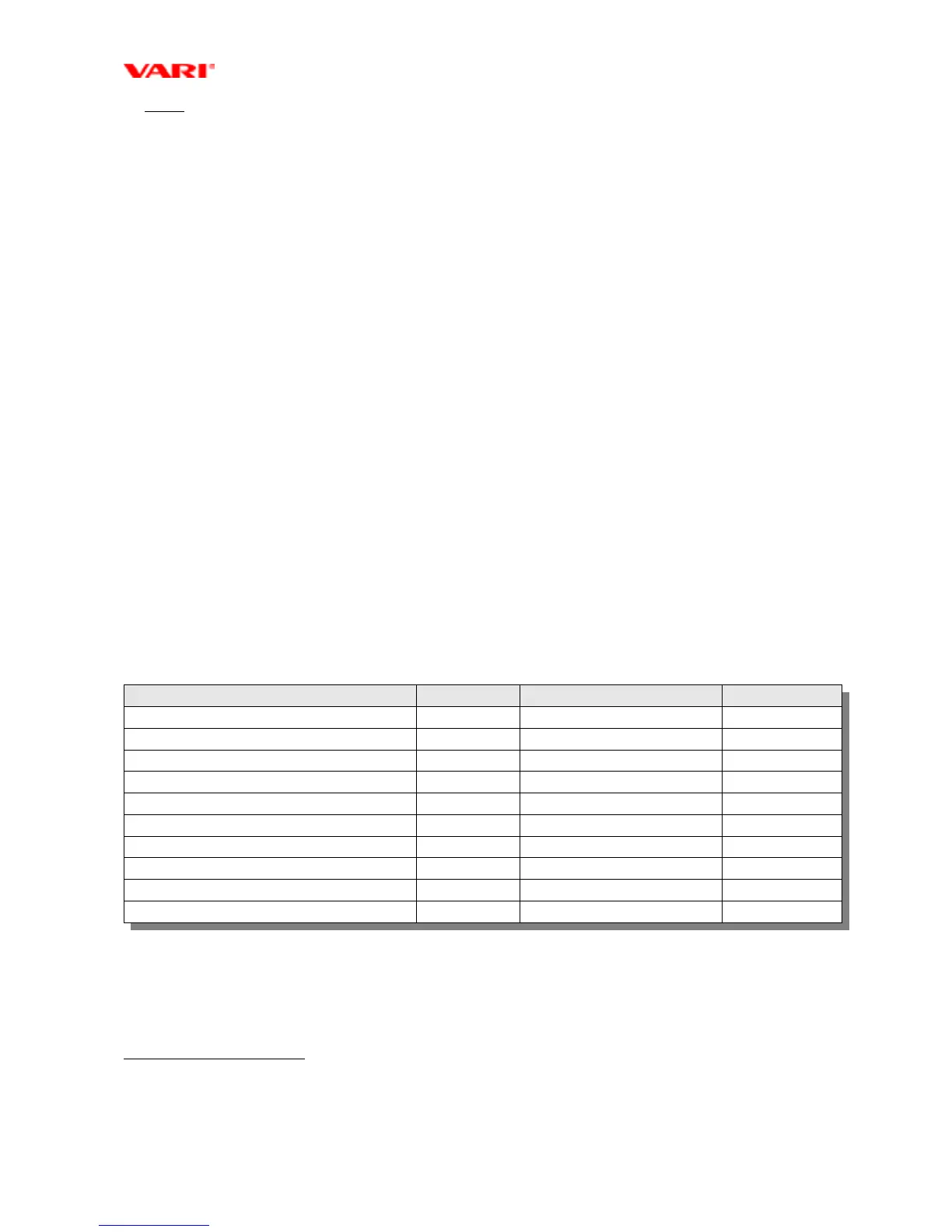

2.5.5 Service intervals

Activity Before cutting In season Before storage

Engine oil level check yes following the engine user manual yes

Cleaning the engine air filter check every 10 hours yes

Washing - 2x yes

Removal of dirt and cut stand remains - after each cutting yes

Blades sharpening - according to need yes

Check the blades and their placing yes immediate exchange if damaged yes

Cutting disk tightening check yes - yes

Bolted connections tightening check yes every 5 hours yes

Lubrications condition check Tab. 5 Tab. 5

V-belts check - every 20 hours yes

Tab. 6: Service intervals

55 You may also use the bolt attached to handlebar rail on the other side of the cable. In this case, screw the bolt in the direction away from the rail.

56 Manifests itself by chattering and irregular belt grip.

57 Use V-belts recommended by the manufacturer only. Proper transmission function cannot be guaranteed when using other V-belts.

58 You may follow opposit instructions. First tighten the screw of the brake cable (towards handebar rail) on the handlebars so that the axial clearance in the adjusting screw

is 1 mm. .

59 The condition of the axial clearance of the brake cable in the adjusting screw is met.

25

Loading...

Loading...