5

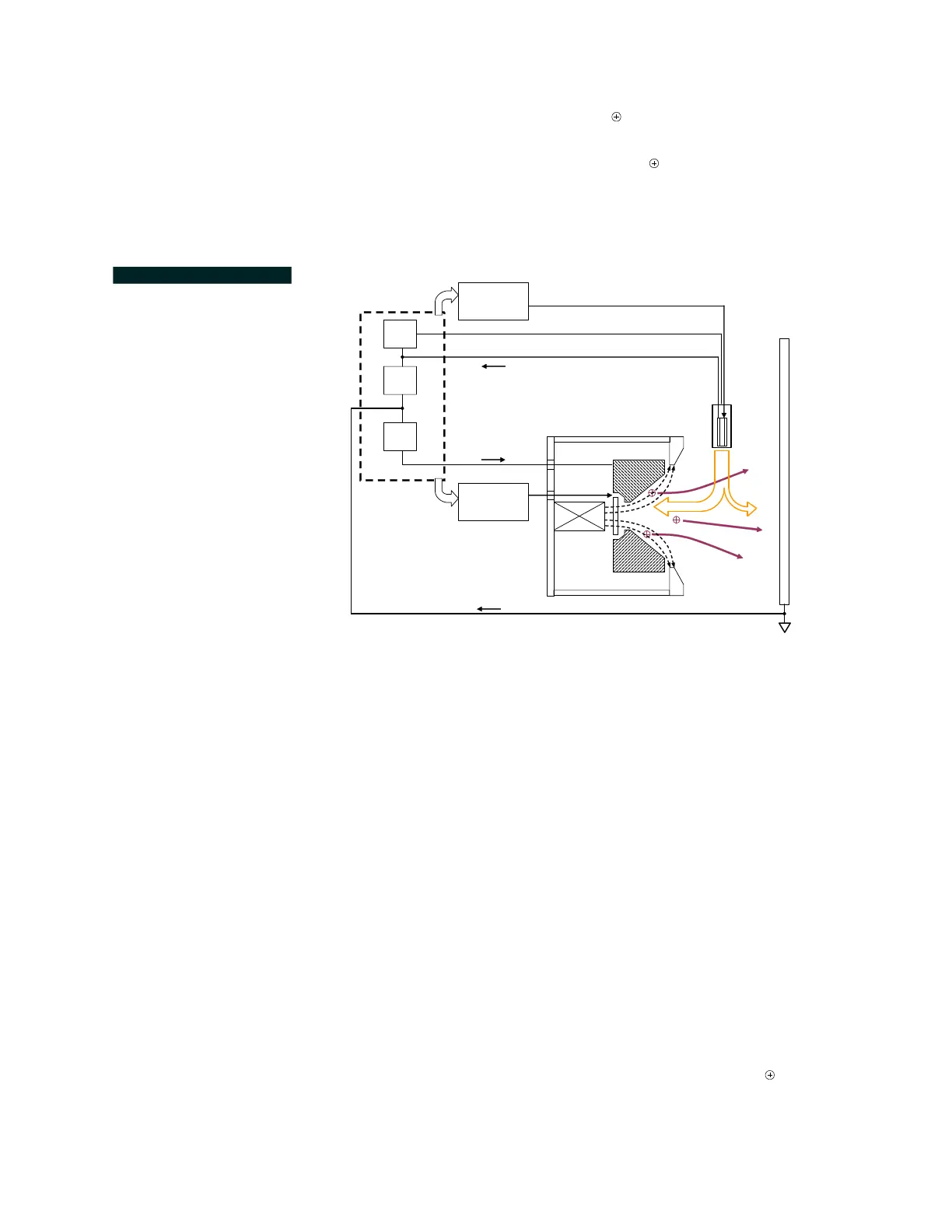

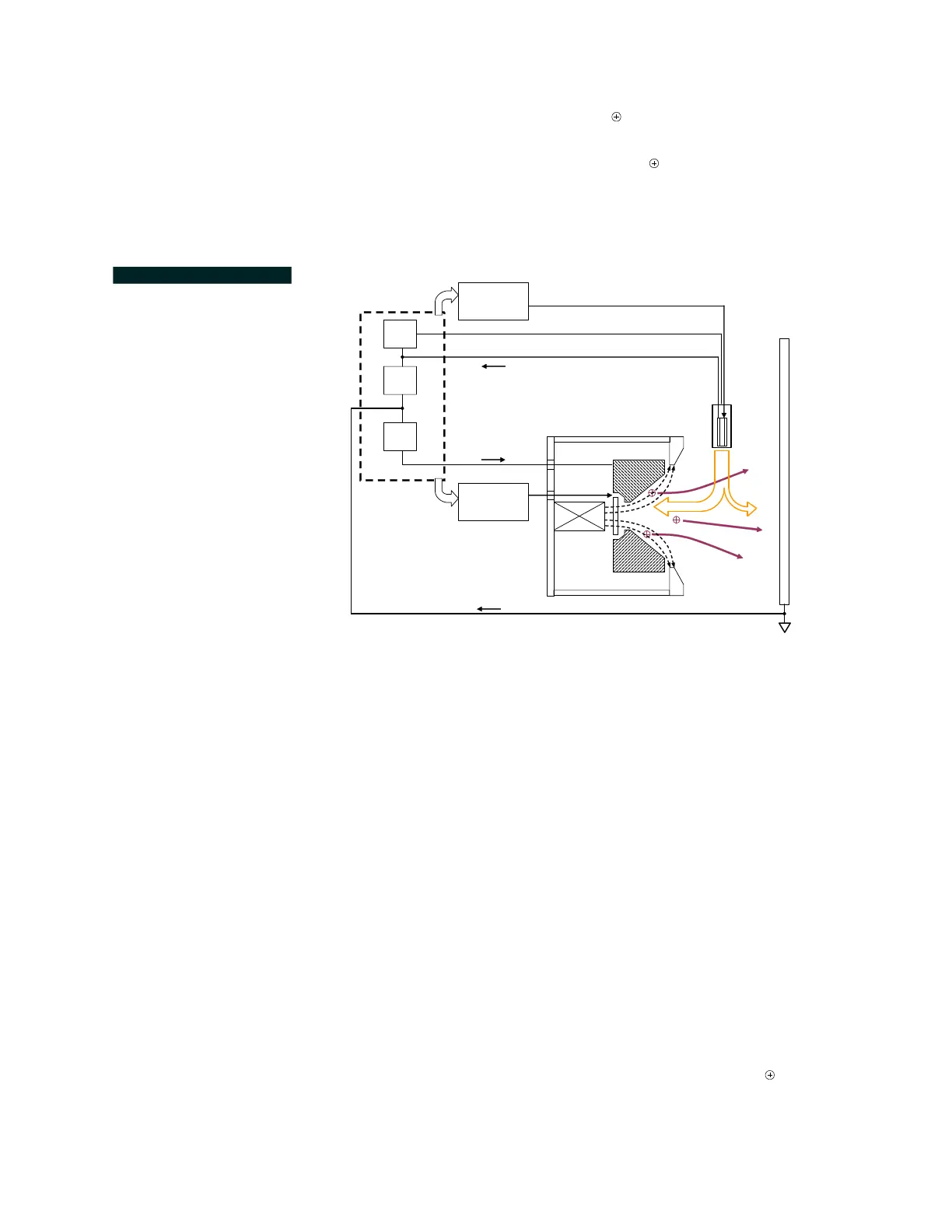

”FIGURE 3.1” on page 4 shows the Mark series ion source’s fundamen-

tal operating principles; FIGURE 3.2 illustrates fluid cooled source opera-

tion, together with its HCES, the Veeco Mark series Controller and

both input mass flow controllers (MFC). The ion source and HCES

require separate MFCs. These components are all provided when this

model is ordered as a package.

First, an argon plasma is ignited in the HCES and sustained with current,

I

K,

provided by the controller’s keeper supply. This supply maintains the

HCES’s thermionic emission temperature, to produce the primary elec-

trons. Second, a gas flow is introduced into the source; the unit applies a

voltage-regulated anode potential, V

A

, to drive the ion source discharge

and produce the ion beam. The controller is able to then automatically

regulate the gas flow to the anode, since the electrical impedance of the

plasma between the anode and cathode depends on input gas conditions.

This provides an anode discharge current I

A

, approximating the operator

requested set point as closely as possible.

The power supply uses a third current-regulated emission supply (posi-

tioned between the cathode and the anode supply return) to provide

additional electrons from the HCES to enhance ion beam neutralization.

This emission supply regulates a portion of the cathode return current,

I

E,

most of which is the anode supply return current, I

A

, and any addi-

tional neutralization current, I

N

, returning through the chamber system

ground. By regulating I

E

, the controller allows the operator to inject an

excess electron neutralization current, I

N

. The recommended value for

I

N

is +10 to +20% of the anode current, I

A

. Refer to the Mark series

Controller technical manual for detailed information.

FIGURE 3.2 Ion Source-

HCES-Controller Operation

with MFCs.

I

A

e

-

Anode

Input

Gas

S

S

NS

V

A

+

I

K

+

HCES

(Cathode)

Mark II+

Controller

Source Mass

Flow Controller

(MFC)

I

E

+I

K

I

E

+

I

N

= (I

E

-I

A

)

Ion Source

HCES Mass

Flow Controller

(MFC)

Loading...

Loading...