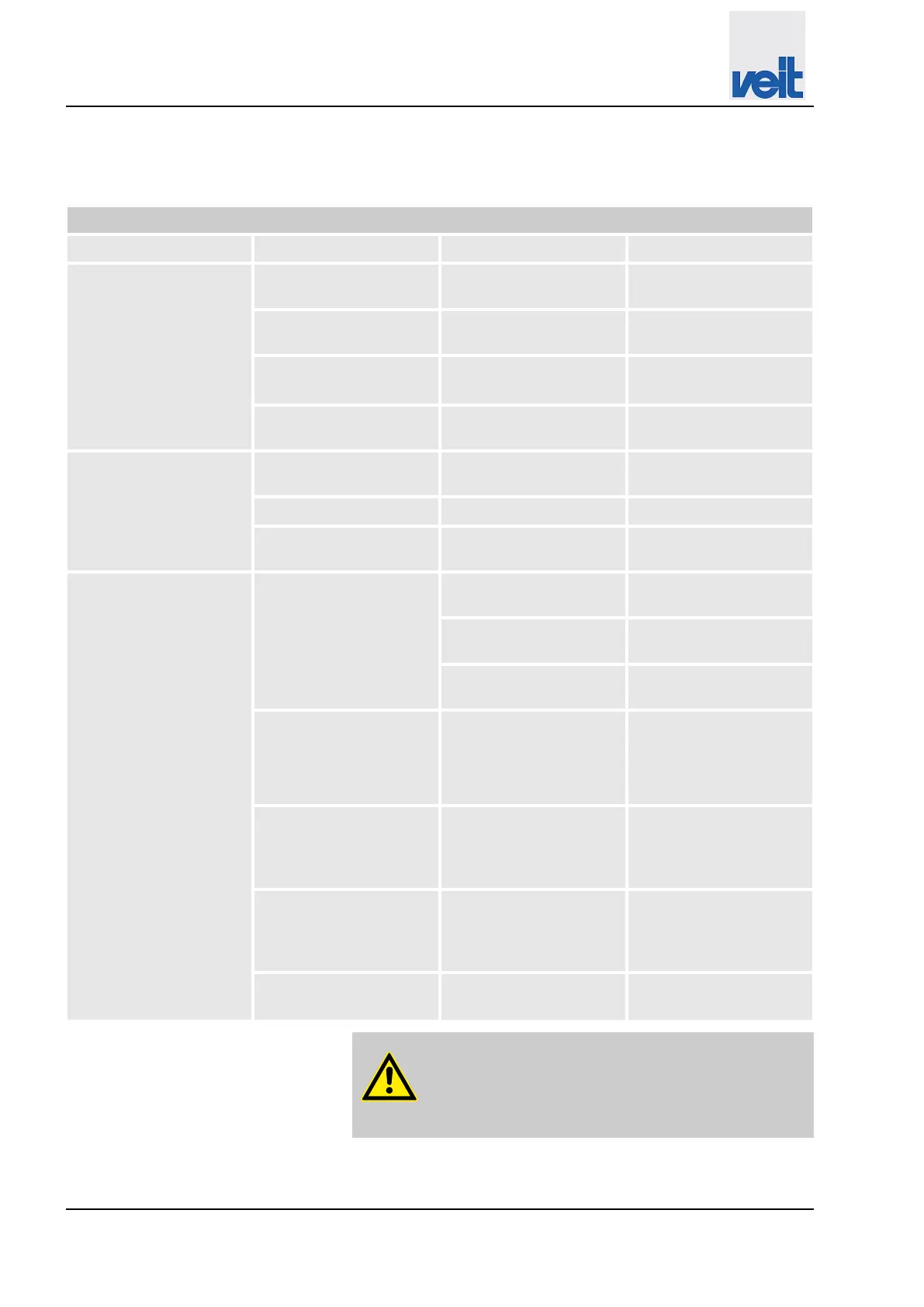

8.1 Maintenance and inspection table

Inspection and maintenance schedule

Interval Part to be inspected Work to be carried out Remarks

Every day Boiler Blow-down (only for

standard version)

Ball valves Leak test Check and replace, if

necessary.

n Pressure gauge

n Pressure regulator

Function check Check and replace, if

necessary.

Steam hoses Check for damages Replace defective steam

hoses.

Every 6 months Steam valve Leak test Check and replace, if

necessary.

All hoses Check for damages Replace defective hoses.

Connection cable Check for damages Replace defective con-

nection cable.

Every year All connections and com-

ponents

Leak test Check and replace, if

necessary.

Corrosion on mounting

clamps

Check and replace, if

necessary.

Tightness Check and replace, if

necessary.

All function parts:

n Pressure gauge

n Pressure regulator

n Check valve

Function check Check and replace, if

necessary.

n Inside of boiler

n Electrode

n Heating elements

n Check for contamina-

tion

n Check for lime

deposits

n Remove contamina-

tions.

n Remove lime

deposits.

n Filling assembly

n Blow-down assembly

n Check for contamina-

tion

n Check for corrosion

n Remove contamina-

tions.

n Replace corroded

parts.

n Filling nozzle

n Blow-down nozzle

Check for lime residue Check and clean, if nec-

essary.

CAUTION!

Safety devices

For checks of the safety devices, please refer to

Ä

Chapter 3.4 ‘Built-in safety devices’ on page 18.

Maintenance and cleaning

Maintenance and inspection table

30.09.2022

Steam generator VEIT SG67

40

Loading...

Loading...