4

© 2023 Veolia. All Rights Reserved. Sievers TOC-R3 Analyzer Installation Guide DQS 95000-01 EN Rev. A

*Sievers is a trademark of Veolia and may be registered in one or more countries.

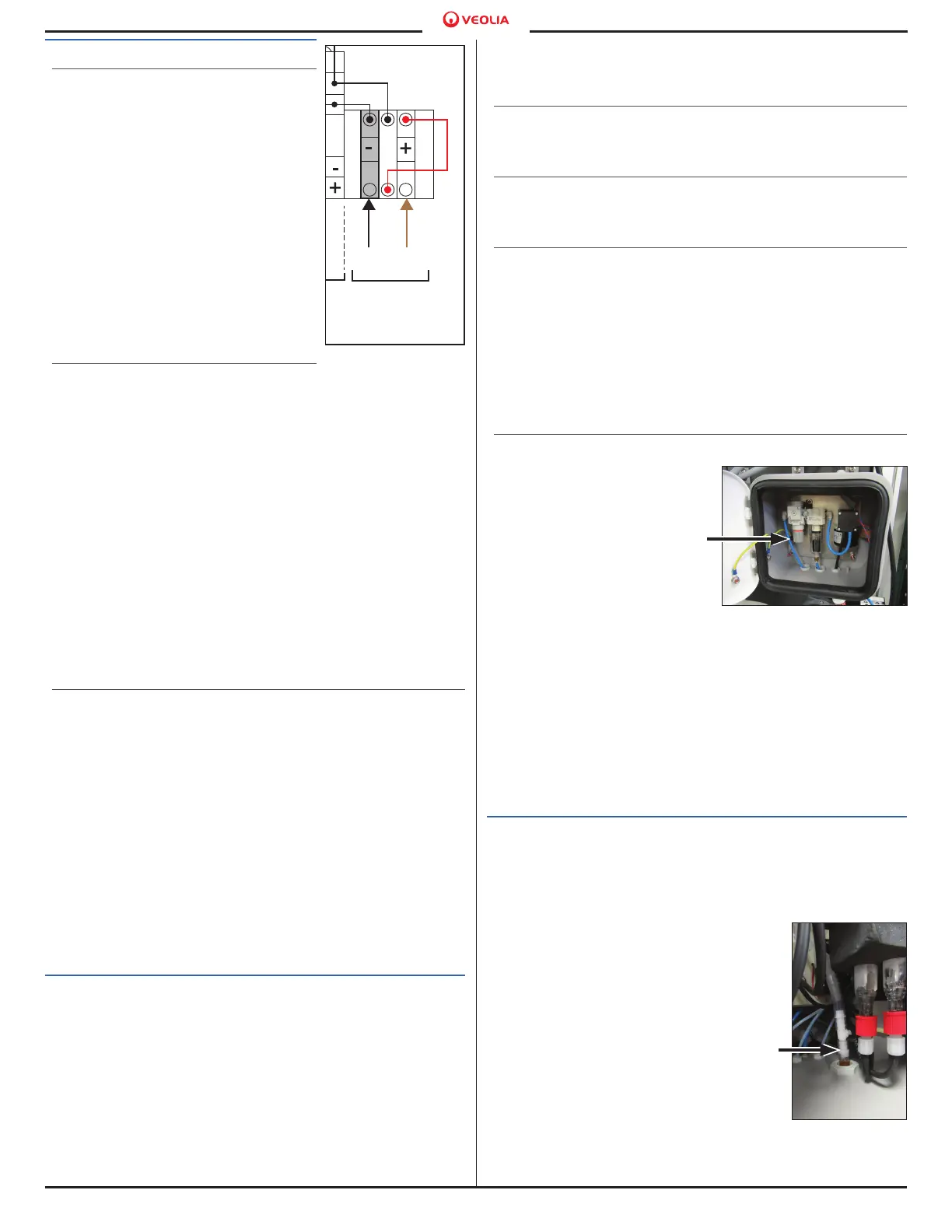

Step 3 — continued...

Connect the Air Box Power

Wires

Route the ±24 V power wires

from the top of the Air Box to

the open port on the top of the

Communication Box. See Figure

2 on page 3. Open the

Communication Box door and

gently pull in any excess cable

length into the enclosure. Do not

allow the wires to bend sharply.

Connect the wires to the power

rail inside the Communication Box

next to the I/O Terminal Block. See

Figure 3.

Prepare the Air Scrubber

Housing

1. Carefully open the bottom

knurled cap (without tubing

ports) to reveal the inside of the Air Scrubber

Housing. The central tube comes pre-installed with

an Activated Carbon Cartridge.

2. Remove the Filter Ring.

3.

4. Reinstall the Filter Ring to seal the outer tube and

contain the Soda Lime granules.

5.

6. Slot the prepared Air Scrubber Housing into the

mounting brackets so that the Inlet and Outlet

ports are oriented on top of the Housing.

Connect the Communication Box to the Analyzer

NOTE: If using the Air Box, ensure the Air Box power

wiring connections have been completed prior to

connecting the Communication Box to the Analyzer.

1. Connect the Right Cable Connector (12-pin

connector on top of the Communication Box) to

Port 13 on the bottom of the Analyzer enclosure.

2. Next, connect the Left Cable Connector (12-pin

connector on top of the Communication Box) to

Port 12 on the bottom of the Analyzer enclosure.

See Figure 2 on page 3.

NOTE: The Right Cable Connector (Port 13) carries

power to the Communication Box power rail from the

Analyzer. See Figure 2 on page 3.

Step 4: Connect the Compressed Gas Source

The Analyzer requires low-CO gas as

and Accessories purchased, the compressed gas

connection, ensure there is an appropriate Pressure

Regulator [maximum of 100 kPa (1 Bar, 14.5 psig)]

installed nearby as well a dedicated Shut-o Valve.

The Analyzer Carrier Gas Inlet (Port 9) uses 6mm

OD, 4mm ID tubing. Cut the Carrier Gas Tubing with

a tubing cutter to length for your environment and

If using Nitrogen:

Connect the Nitrogen source Carrier Gas Line to the

Analyzer Carrier Gas Inlet (Port 9).

If using Zero/Synthetic Air:

Connect the Zero/Synthetic Air source Carrier Gas

Line to the Analyzer Carrier Gas Inlet (Port 9).

If using Plant Instrument Air (ANSI/ISA 7.0.01):

1. Connect the compressed Plant Instrument Air

source to the Air Scrubber Inlet (central port on

top of Air Scrubber Housing). Both the Analyzer

and Air Scrubber connection ports use 6 mm OD

tubing.

2.

top of Air Scrubber Housing) tubing to the Analyzer

Carrier Gas Inlet (Port 9).

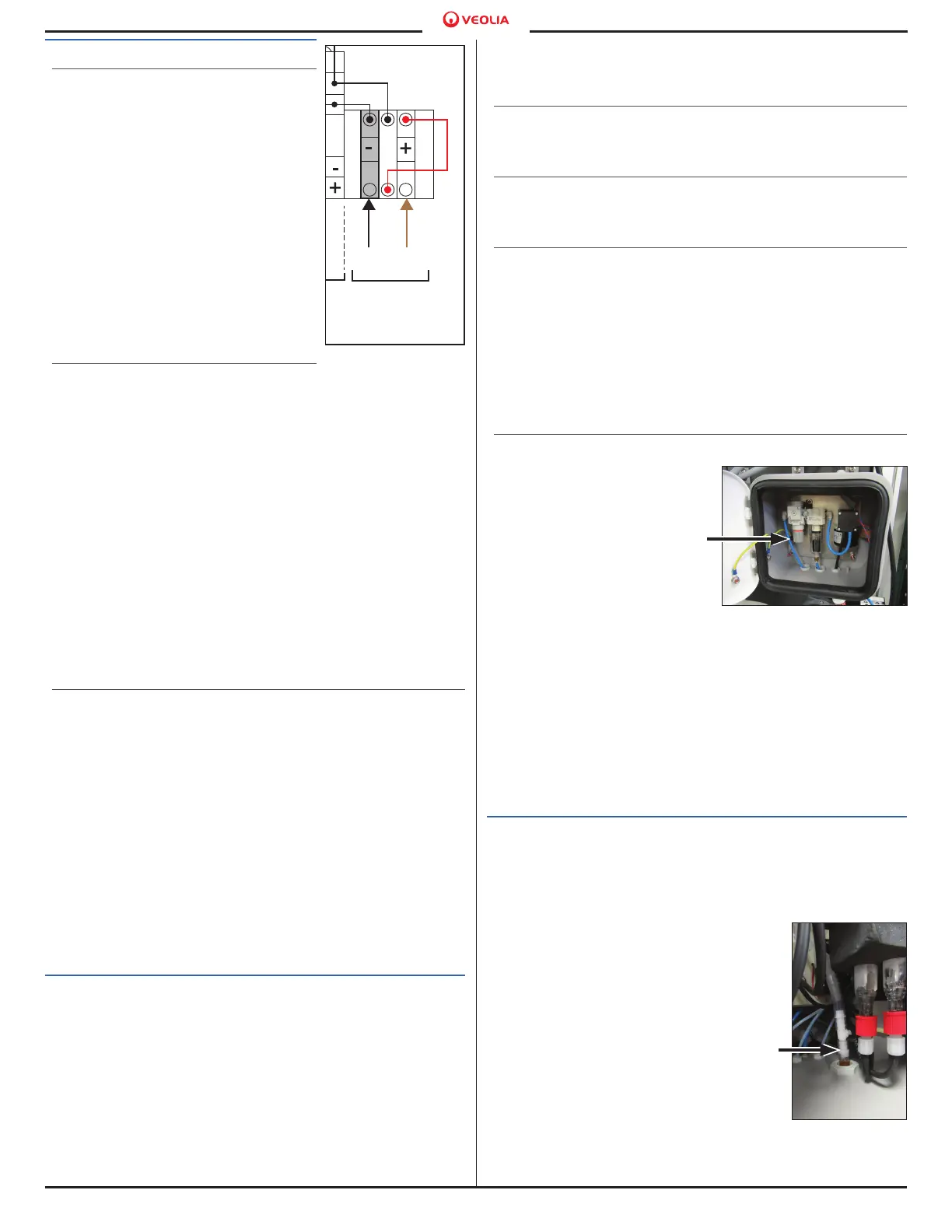

If using Air Box Accessory:

NOTE: The Air Box has its

own Pressure Regulator

inside the enclosure.

1. Open the Air Box door.

2. Route the Carrier Gas

Tubing into the bottom

of the Air Box enclosure

through the hole shown.

See Figure 4.

3. Install the Carrier Gas

Tubing to the Outlet (left side) of the internal

Pressure Regulator.

4. Install the other end of the Carrier Gas Tubing to

the Air Scrubber Inlet (central port on top of Air

Scrubber Housing).

5.

top of Air Scrubber Housing) Carrier Gas Tubing to

the Analyzer Carrier Gas Inlet (Port 9).

Step 5: Connect the Waste Line

Locate the Waste Tubing [18] in the Shipping Kit. See

"Table 3. Shipping List" on page 9. Important!

The Analyzer requires a gravity drain with little to

no back pressure [less than 7 kPa (0.07 Bar, 1 psig)].

1. Open the Analyzer door and

locate the Gas Cooler Unit Drain

T-Fitting in the bottom right

compartment of the Analyzer.

2. Route the Waste Tubing up into

the Analyzer through Port 2. This

Figure 5.

3. Connect the Waste Tubing [18] to

the barb on the Gas Cooler Drain

T-Fitting. Ensure that the tubing

is fully inserted on the barb. See

Figure 5 and Figure 6 on page

5.

Figure 3.

Not Used

1 2 3 4 5 6 7 8 9 10

14 14 14 14

11 11 11 11

12 12 12 12

11 12 13 14 15

16

Option: From

Air Box Accessory,

Customer

connection.

01 02 03 04 05 06 14 15 16 17 12 13 14 15 16 17

Analog Output

(Connects to

Sensor Board)

0/4 - 20 mA Max. Load

V: 250 VAC

I: 5 A

V: 24 VAC, I: 2 A

0 - level: DC 0... 5 V

1 - level: DC 18... 30 V

Digital Output

(Connects to Digital I/O Board)

Indicates

Connection

on Circuit

Board

-24V

+24V

-24V

+24V

BLK BRN

Digital Input

Signal Strength by I/O Type

Lower terminal I/O Connections made by Customer

Upper terminal wires connected at the factory

NO NO NO NO

NC NC NC NC

Detail:

Air Box Power

Connections on

Communication Box

I/O Terminal Block

Figure 4. Air Box Carrier Gas

Tubing

Figure 5. Connect

the Waste Tubing

[18]

Loading...

Loading...