8

© 2023 Veolia. All Rights Reserved. Sievers TOC-R3 Analyzer Installation Guide DQS 95000-01 EN Rev. A

*Sievers is a trademark of Veolia and may be registered in one or more countries.

Step 11: Set the Local Analyzer Settings

Navigate to the following: Menu → General. From

this screen you can set the local Analyzer settings.

Select the buttons below to adjust any of the following

settings.

• System Settings: Set the Language, Dark Mode,

Name(s), if desired.

• Time/Date Settings: Set the local Time and Date.

NOTE: This will require a system reboot.

• Ethernet: Set up the Ethernet Connection, if using.

For more information, consult the Manual. (Ethernet

cable is Customer provided)

Step 12: Perform Initial Analyzer Diagnostics

From the Touchscreen, select the Menu button (or use

Menu

screen).

Unlock the Analyzer

Unlock the Analyzer by selecting the Lock Icon in the

bottom left corner and inputting the default Machine

PIN “1111”. This pin can be changed at a later time.

For more information, consult the Manual.

Check the Sensor Values

Navigate to the following: Menu → Service →

Sensors. Observe the values being displayed. Only

installation. See Table 2 on page 8.

Adjust the “Carrier Gas Flow In” to the Analyzer

From the external Pressure Regulator or Air Box

Pressure Regulator (depending on the Analyzer

Flow IN to the Analyzer to be 25 liters per hour (l/h).

Sensors screen displays 25 l/h.

NOTE: If using Air Box, turn the Air Box Pressure

Regulator

Exercise the Valves

Navigate to the following: Menu → Service → Valve

Control. Select each valve to Open and Close the

Open and Close each valve ve times.

NOTE: The Y8 Valve is not used and will not cycle

when exercised. The Y10 and Y11 Valves are

powered together.

Check the Pumps

Navigate to the following: Menu → Service → Pump

Control. Working one at a time, select the Start

button for GP1, GP2, and GP4

that the hardware initiates when started. Press the

Stop

ve seconds.

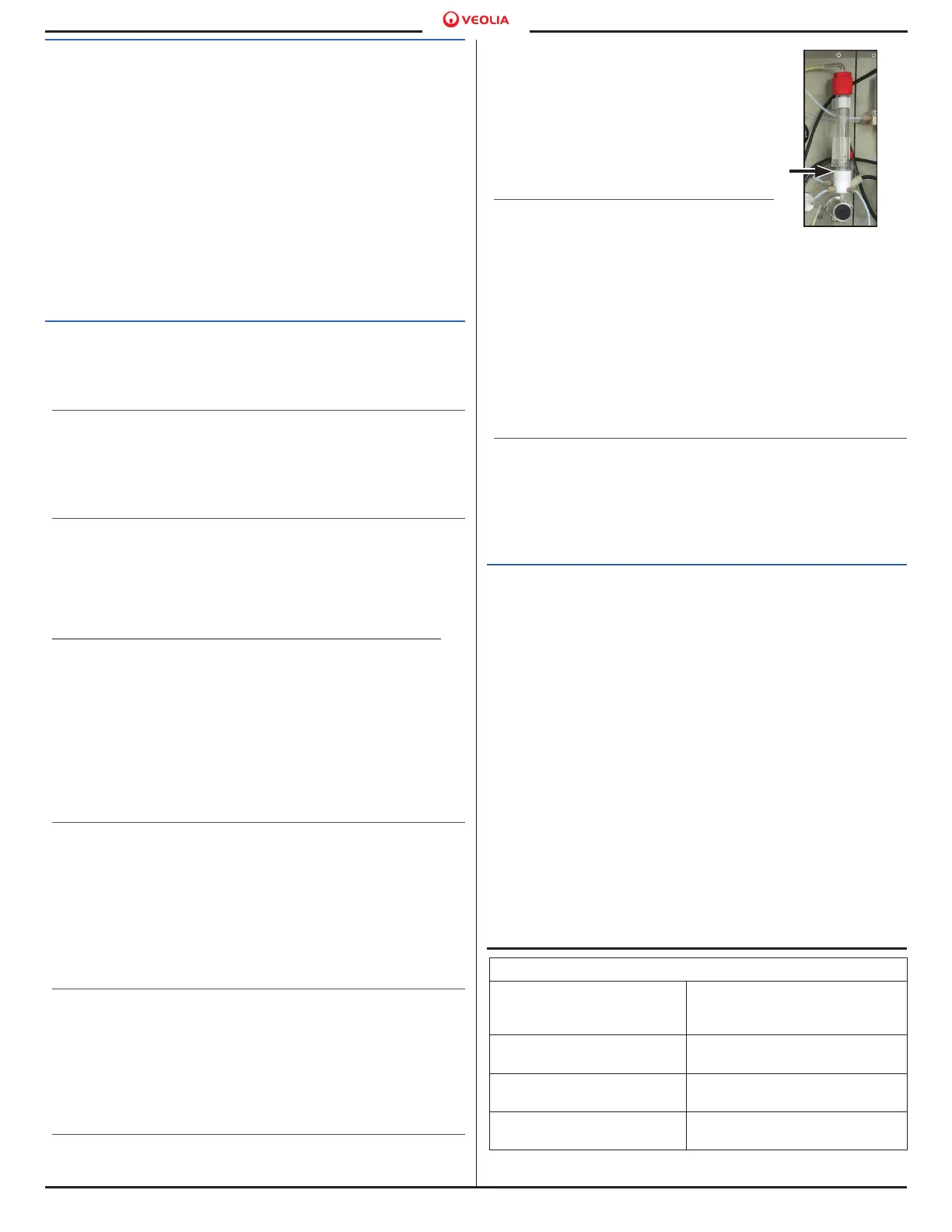

Prime the Acid Pump (GP3)

From the same screen, press the GP3 Pump button

about 50 times to fully prime the

Acid Pump. Each “Pump” pulse

will pull 200 µL of Acid into the

Acid Tubing. The Acid Pump is

considered primed once the Acid

of the Multi-function Sample Vessel

(MFSV). See Figure 17.

Clear any Analyzer Errors

The Analyzer will be displaying at

least one Error Code due to the

startup procedure. This is known and expected.

All Errors must be acknowledged by the User. To

view the current Error(s), either select the Error

button in the top right corner or the Error Icon (red

circle with a white “X”) in the bottom right corner to

view the System Information Screen. Select any

Functional Modules (Software, Electronics, Furnace,

or Sampling) with Error Codes displayed (starting with

“E1”) and Acknowledge them.

Test Input/Output Connections

If using the Communication Box for Input/Output

(I/O) control within the Analyzer, you must test that

these connections are working. For more information

consult the Manual.

Step 13: Installation Complete

The installation is now complete.

Figure 17. MFSV

Table 2. Sensor Values (Menu → Service → Sensors)

Carrier Gas Flow In —

should display ± 5 l/h to

“Carrier Gas Flow Out” value.

Carrier Gas Flow Out — should

display ± 5 l/h to “Carrier Gas

Flow In” value.

Pressure Reactor — should

display less than 50 mbar.

Temperature 2* — should be

between 30-40 °C.

Furnace Temperature —

should display 1200 °C.

Gas Cooler — should

display 5 °C.

Gas Cooler Environment —

should be between 30-40 °C.

*Temperature 1 Sensor is not used.

Loading...

Loading...