7

© 2023 Veolia. All Rights Reserved. Sievers TOC-R3 Analyzer Installation Guide DQS 95000-01 EN Rev. A

*Sievers is a trademark of Veolia and may be registered in one or more countries.

Step 9 — continued...

3. While holding the Injection Needle [15] in one

hand, carefully loosen the Compression Nut

[10A] with the other. Important! Do not let go of

the Injection Needle! It will fall into Furnace

Cartridge! See Figure 12.

4. Carefully slide the Injection Needle [15] up and

insert it into the Injection Block port. Ensure that

the Ferrule [14B] seats into the Injection Block

and then tighten the Injection Block Compression

tight.

5. Next, re-tighten the Compression Nut [10A] to be

See Figure 12 on page 6.

Install the Furnace Foot Assembly

Locate items [12], [13], [16], and three of item [17].

1. Temporarily disconnect the Transfer Tube from the

Furnace Foot Assembly [12]. It will be reattached

in a later step.

2. Insert the small Ceramic

Disk [16] into the center of

the Furnace Foot Assembly

[12]. Ensure the Disk is laying

Assembly [12]. Important!

Failure to install this correctly

will result in hardware failure!

See Figure 13.

3. Orient the Furnace Foot Assembly [12] so that the

Transfer Tube Port is on the right side.

4. Working from below through

the Furnace Access Port,

gently push the Furnace Foot

Assembly [12] on to the bottom

of the Furnace Sleeve [2]

extending out from below the

Furnace. Ensure the Transfer

Tube Port is oriented at a

45° angle between the Gas

Cooler Unit and the front of the

Analyzer. See Figure 14.

• NOTE: If the desired angle is not achieved on

[12] anticlockwise until the desired position is

obtained. Do not rotate clockwise or it will

loosen the ttings inside the Furnace Foot

Assembly [12] and risk

hardware failure!

5. Working one at a time, carefully

install the three Furnace Foot

Z-Brackets [13] to the bottom

of the Furnace using the three

Thumb Screws [17].

6. Rotate the Furnace Foot Z-Brackets [13] to slot

and clamp onto the Furnace Foot Assembly [12]

groove. Tighten the three Thumb Screws [17] to be

Figure 14 and Figure 15.

NOTE:

area.

7. Working from the right side compartment into the

left side compartment inside the Analyzer, pull the

Transfer Tube through the lower opening toward

the Furnace Foot Assembly [12].

8. Reconnect the Transfer Tube to the Furnace Foot

Assembly [12].

9. Set the loose end of the Transfer Tube next to the

Gas Cooler Unit in the right side compartment of

the Analyzer. It will be connected in a later step.

Do not connect it to the Analyzer. Leave it

open to atmosphere. Failure to do this may

result in hardware failure in the future due to

contaminants entering the system.

10. Reinstall the Furnace Access Cover.

Step 10: Connecting to a Power Supply

Connect power to the Analyzer in accordance with

local regulations and facility guidelines. A qualied

electrician must perform all electrical installation

activities. For more information, consult the Manual.

Ensure all power connections are made with the

POWER OFF.

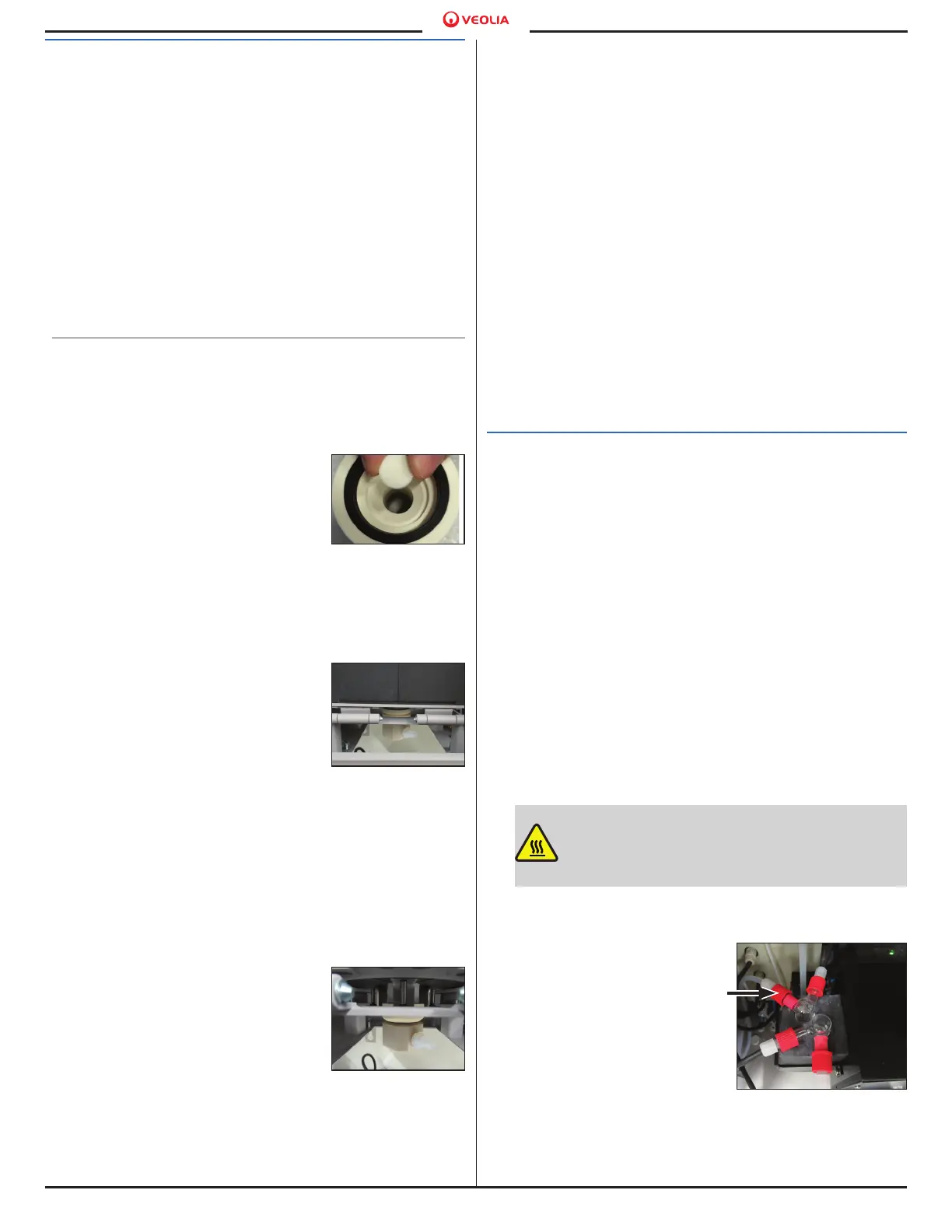

• Power ON the Analyzer by turning the Rotary

Power Switch on the right side of the Analyzer to

the vertical, ON position.

•

hardware have power before continuing. With the

Analyzer door open, observe the Gas Cooler Unit

in the lower right side compartment of the Analyzer.

The right, Red LED will illuminate while it is cooling

down to temperature. The left, Green LED will

illuminate once the system is at temperature (about

10 minutes). See Figure 6 on page 5 and

Figure 16.

Caution! Very Hot temperatures! Do not

touch the Furnace, Furnace Head Assembly,

or Furnace Foot Assembly without proper

PPE.

Important! Allow the Analyzer to run for two hours

before continuing to the next step. The Furnace must

heat up to temperature (1200

°C, 2192 °F) and be allowed

manufacturing residues.

After two hours, connect the

loose end of the Transfer

Tube to the Gas Cooler

Unit. See Figure 16. Ensure

to use proper PPE while

working inside the Analyzer.

The Analyzer system is now

closed. Close the Analyzer

door.

Figure 13.

Ceramic

Disk [16]

Figure 14. Furnace

Foot Assembly [12]

groove and correct

orientation

Figure 15. Furnace

Foot Assembly

Z-Brackets

Figure 16. Gas Cooler Unit

and LED (View from above)

Loading...

Loading...