30.82

Series 769 FireLock NXT™ Preaction Valve 11

AIR SUPPLY REQUIREMENTS

The required air pressure for Series 769 FireLock NXT Preaction Valves is 13 psi/90 kPa minimum,

regardless of the system supply pressure. Air pressures should be kept below 18 psi/124 kPa, unless a

Series 746 Dry Accelerator is installed. Systems with air pressures higher than 18 psi/124 kPa require the

addition of a Series 746 Dry Accelerator.

If multiple Series 769 FireLock NXT Preaction Valves are installed with a common air supply, isolate the

systems with a spring-loaded, soft-seated ball check valve to ensure air integrity for each system. Good

practice is to include a ball valve for isolation and service of each individual system.

Set the air pressure to the required system air pressure. Air pressure differing from the required system

air pressure could reduce system operation response time.

The engineer/system designer is responsible for sizing the compressor so that the entire system is

charged to the required air pressure within 30 minutes. DO NOT oversize the compressor to provide more

airflow. An oversized compressor will slow down or possibly prevent valve operation.

If the compressor fills the system too fast, it may be necessary to restrict the air supply. Restricting the air

supply will ensure that air being exhausted from an open sprinkler or manual release valve is not replaced

by the air supply system as fast as it is being exhausted.

Compressor Sizing

Base or Riser-Mounted Compressors

For base or riser-mounted compressors, the recommended air pressure of 13 psi/90 kPa is the “on” or

“low” pressure setting for the compressor. The “off” or “high” pressure setting should be 18 psi/124 kPa.

When a base or riser-mounted air compressor supplies air to a Series 769 FireLock NXT Preacation Valve,

it is not necessary to install the Victaulic Series 757 Regulated Air Maintenance Trim Assembly (AMTA).

In this case, the airline of the compressor connects to the trim at the fitting where the Series 757

Regulated AMTA is normally installed (refer to the applicable trim drawing). If the compressor is not

equipped with a pressure switch, the Series 757P Air Maintenance Trim Assembly with Pressure Switch

should be installed.

Shop Air or Tank-Mounted Air Compressors

In the event a compressor becomes inoperative, a properly sized tank-mounted air compressor provides

the the greatest protection for systems.

When shop air or a tank-mounted air compressor is used, the Series 757 Regulated AMTA must be

installed. The Series 757 Regulated AMTA provides proper air regulation from the air reservoir to the

sprinkler system.

For tank-mounted air compressors, the recommended air pressure of 13 psi/90 kPa should be used as

the set point for the air regulator. The “on” pressure of the compressor should be at least 5 psi/34 kPa

above the set point of the air regulator.

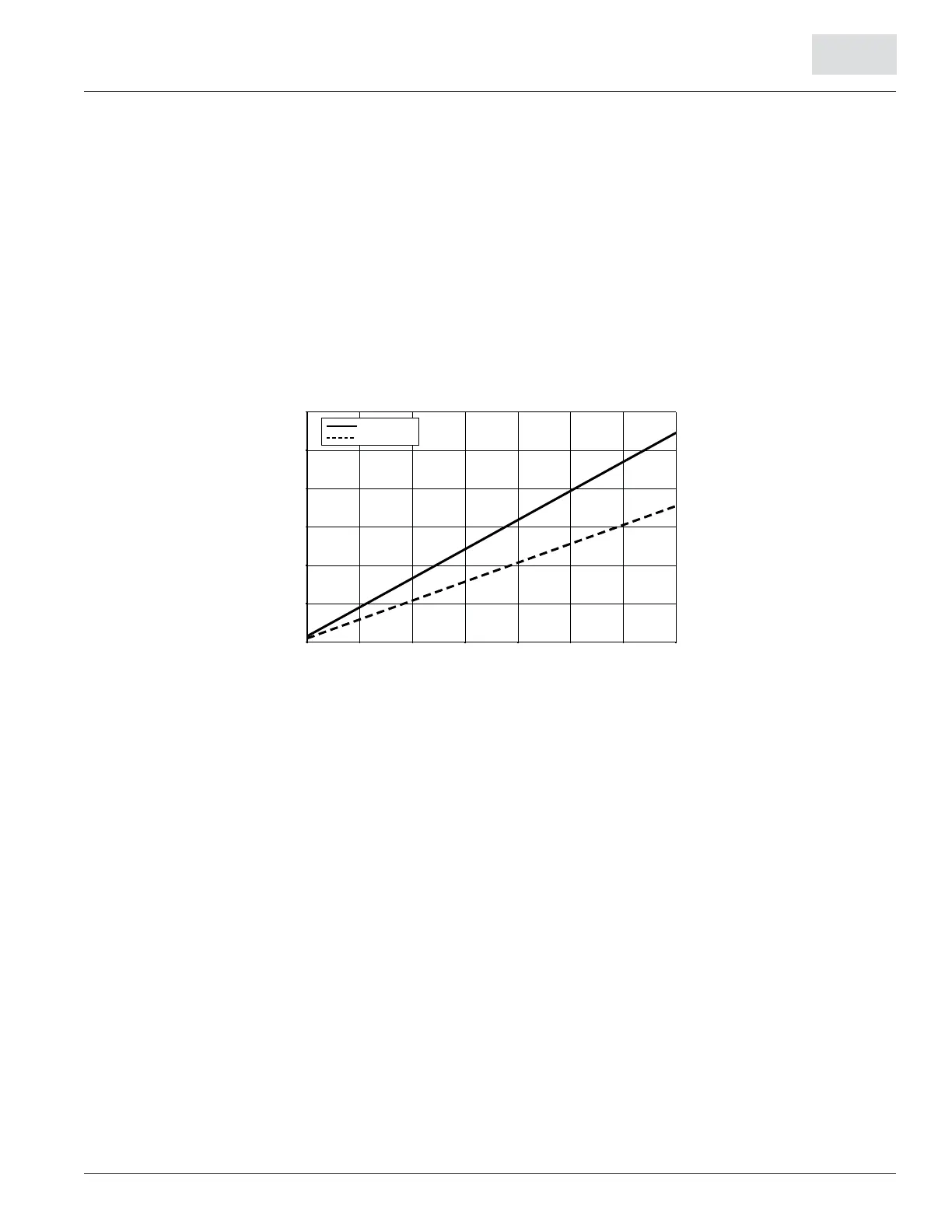

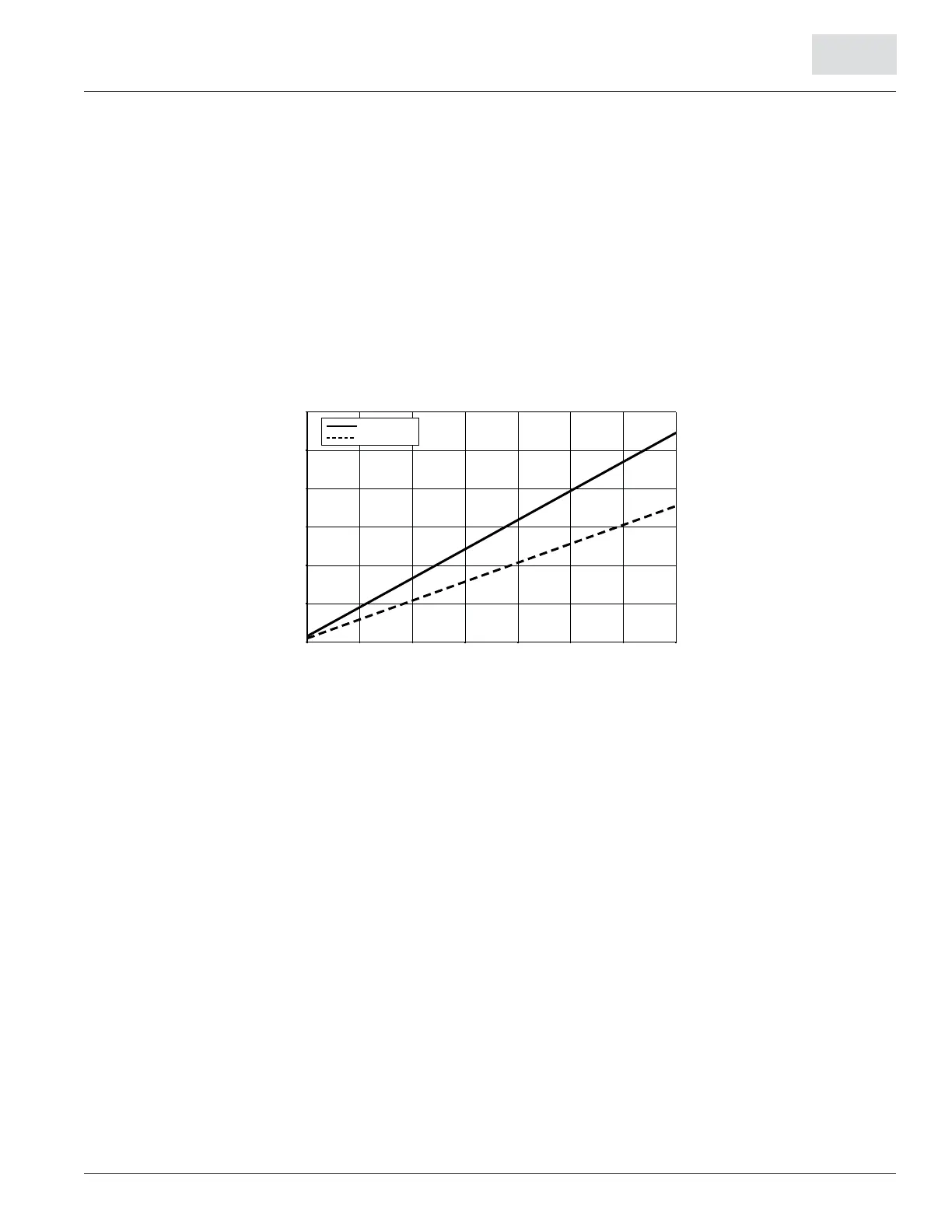

0

2

4

6

8

10

12

System Capacity (in gallons)

Required Flow Rate (CFM)

COMPRESSOR REQUIREMENTS

550

300

50

800

1050

1300

1550

1800

20 psi/138 kPa

13 psi/90 kPa

Loading...

Loading...