8

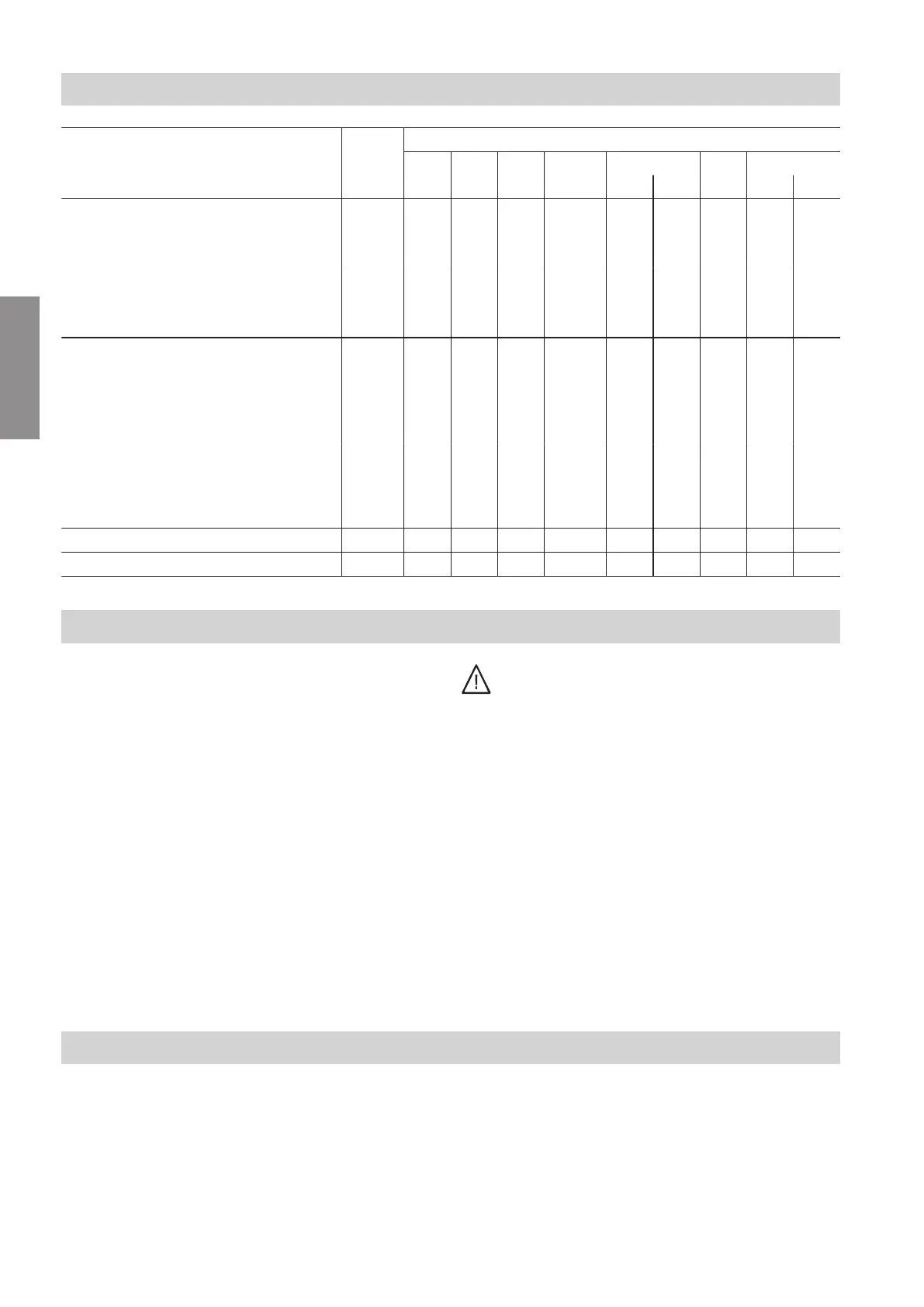

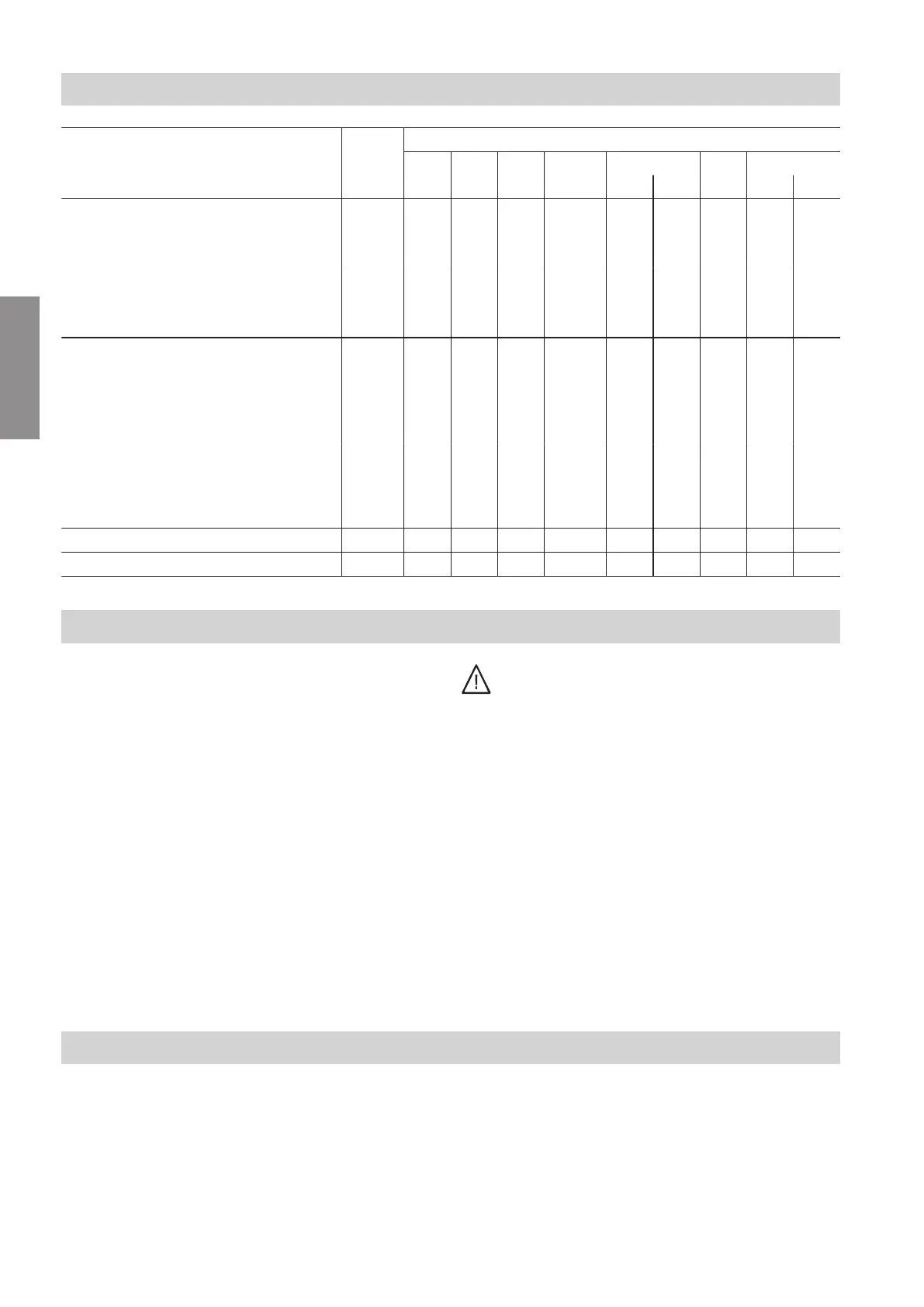

Function Page Connections:

DI1 DI2 DI3 PWM1 0 - 10 V

hH fD

IN OUT 43-1 43-L

External functions

■

External default set flow temperature 8 X X

■

External default output 9 X X

■

Operating mode changeover 10 X X X

■

External demand 10 X

■

External blocking 11 X

Fault message input and fault mes-

sage output

■

Connection without system blocking 11 X X

■

Connection with system blocking,

230 V

12 X X

■

Connection with system blocking,

24 V

13 X X

■

Connecting only message facility (e.g.

buzzer)

13 X

External LPG valve 13 X

External extractor interlock 13 X

Electrical connections

!

Please note

Electronic assemblies can be damaged by elec-

trostatic discharge.

Prior to commencing any work, touch earthed

objects such as heating or water pipes to dis-

charge static loads.

■

Apply strain relief to on-site cables.

■

Seal any unnecessary apertures with cable grom-

mets (not cut open).

Danger

Incorrect wiring can lead to serious injury from

electrical current and result in appliance dam-

age.

Take the following measures to prevent wires

drifting into the adjacent voltage area:

■

Route extra low voltage (ELV) leads < 42 V

separately from cables > 42 V/230 V~/400 V~.

Secure with cable ties.

■

Strip as little of the insulation as possible,

directly before the terminals. Bundle the

cables close to the corresponding terminals.

■

If 2 components are connected to the same

terminal, press both cores together in a single

wire ferrule.

■

When connecting external switching contacts

and on-site components, observe the insula-

tion requirements of IEC/EN 60335-1.

Connecting external functions

Connecting external default set flow temperature: 0 - 10 V IN

Analogue input for connecting the external default set

flow temperature or the external default output

Installation sequence

Overview of electrical connections (cont.)

6131087

Installation

Loading...

Loading...