Start-up and Service

11

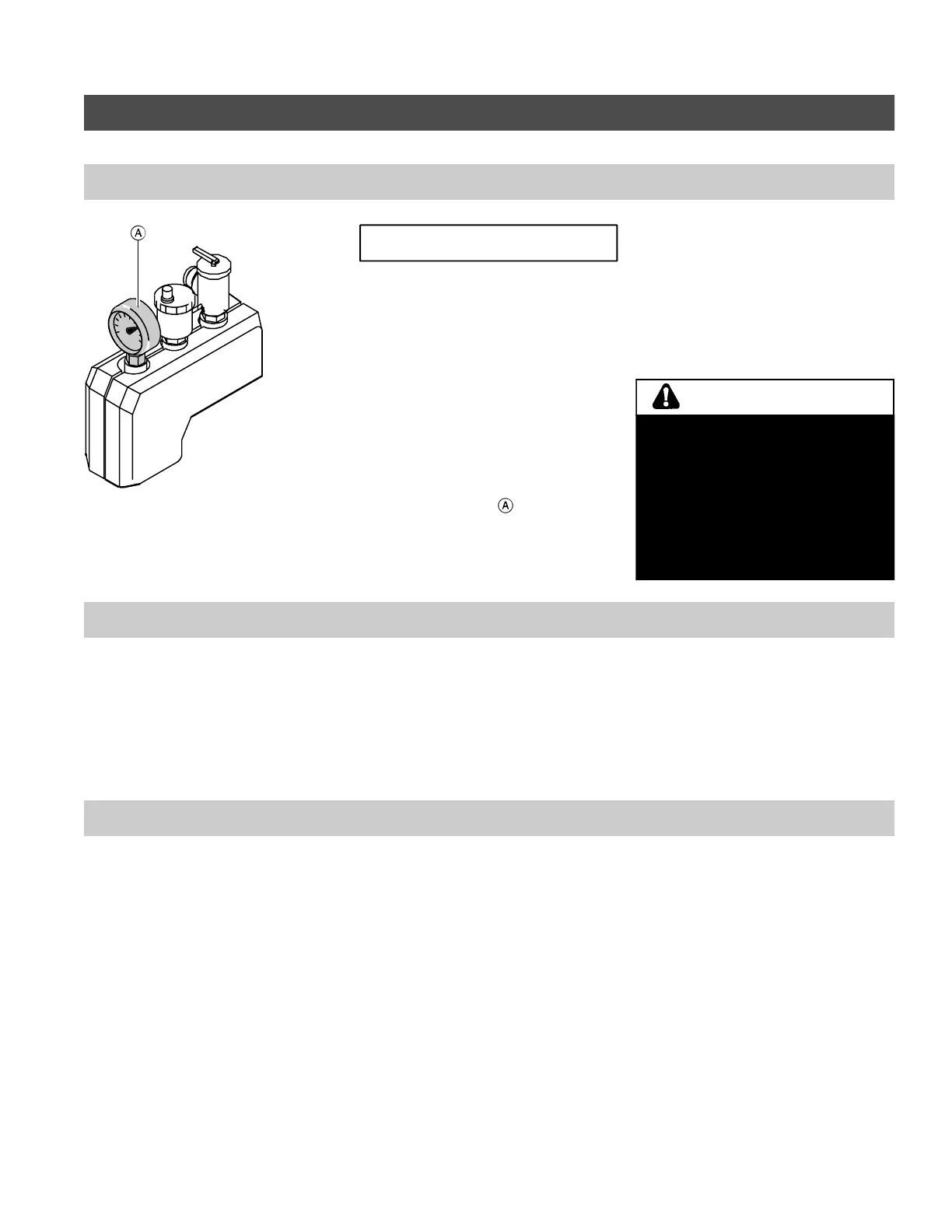

8. Ensure proper operation of automatic fill valv e and expansion tank; also ensure proper system water pressure

Check fill pressure when system is cold.

Ensure proper operation of automatic fill

valve and expansion tank.

If a non-diaphragm expansion tank is

used, ensure the correct water level is

present (expansion tank should be

2

/

3

full).

The usual water fill press ure is between

10 and 15 psi with the system cold.

Check pressure gage

on safety

header. All leaks must be corrected.

Refer to manufacturer’s instructions for

each of the components listed above.

9. Ensure enclosure panels are correctly fitted

1. Ensure all enclosure panels are

seated properly; adjust as necessary.

2. Ensure strain reliefs on rear panel are

tight and seated properly.

10. Ensure mixing valve(s) rotates easily and is pressure t ight (if installed)

1. Remove mixing valve lever.

2. Check if mixing valve rotates easily.

3. Ensure mixing valv e is pressure tight

(does not leak). Replace O-Ring seals

if necessary.

4. Reinstall mixing valve lever.

Service (continued)

5167 405 v2.2

IMPORTANT

This boiler is not for use in systems

where water is constantly or

frequently replenished. Minerals such

as calcium in make-up water can

deposit on heat exchanger causing

overheating, and eventually the boiler

will leak. This type of failure is not

covered by warranty. Water must not

be drained from system for use by

cleaning personnel.

CAUTION

Loading...

Loading...