Start-up and Service

7

See Operating Instructions, Serv ice Instructions of

Power Burner and Boiler Control

1. Ensure combustion and ventilation air

openings of boiler room are open and

that chimney and all flue pipes are

connected, sealed and unobstructed

inside. Verify that all requirements in

the Combustion Air Supply section of

the boiler Installation Instructions are

met.

2. Ensure proper operation of expansion

tank (see Maintenance/Service

manual).

3. Ensure that system piping is flushed

out to remove debris and/or sludge.

Failure to do s o could cause

settlement in the boiler causing

overheating and damage not covered

by warranty.

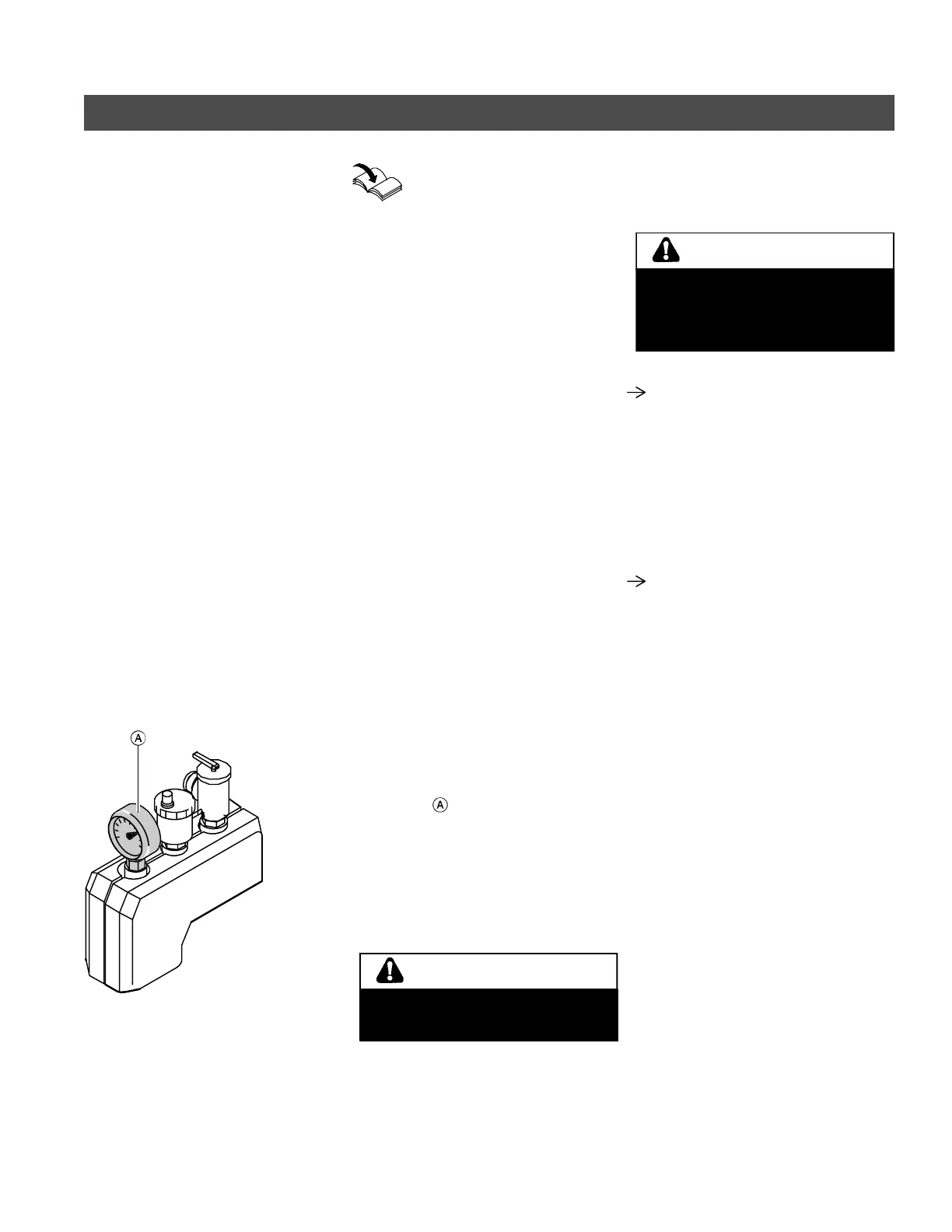

4. Fill heating system with water and

bleed out air completely. Ensure

complete system is properly vented

of air.

Max. system operating press.

<30 psig

....................................................

Pressure relief discharge press.

30 psig

........................................................

5. Perform a pressure test of the boiler

and the water piping. Pressure test

must not exceed 1½ times the

maximum system operating pressure

(45 psig

) of t he boiler. Pressure

relief valve must be removed during

pressure test . Any leaks must be

corrected.

6. Ensure fuel proper/adequate fuel

supply exists; open oil or gas shut-off

valve.

7. Verify completeness of all discussion

points on the following pages in the

section entitled Service before

starting up system.

If the nitrogen pressure of the

precharged expansion tank is less

than the static pressure of the

system, inflate membrane pressure to

slightly exceed pressure of system.

The static pressure required at the

tank is based upon the static height

of the system.

Water treatment should be considered

in areas where it is known that boiler

feed water contains a high mineral

content and hardness.

In areas where freezing might occur,

an antifreeze may be added to the

system water to protect the sys tem.

Please adhere t o the specifications

given by the antifreeze manufacturer.

Do not use automotive silicate-based

antifreeze.

Please observe that an

antifreeze/water mixture may require

a backflow preventer within the

automatic water feed and influence

components such as diaphragm

expansion tanks, radiation, etc. A

40% antifreeze content will provide

freeze-up protection to -10°F / -23°C.

Do not use antifreeze other than

specifically made for hot water

heating systems. Sys tem also may

contain components which might be

negatively affected by antifreeze.

Check total system frequently when

filled with antifreeze.

Initial Start-up

5167 405 v2.2

DO NOT USE GASOLINE

CRANKCASE DRAININGS OR ANY

OIL CONTAINING GASOLINE.

WARNING

Keep boiler clear and free from

combustible materials, gasoline, and

other flammable vapors and liquids.

Do not obstruct the flow of

combustion and ventilation air.

WARNING

Loading...

Loading...