Gasifying boiler VIGAS

15. BOILER MAINTENANCE AND REPAIRS

15.1 DOOR SEAL

15.2 CHIMNEY FLAP TIGHTNESS

15.3 Heatproof nozzle

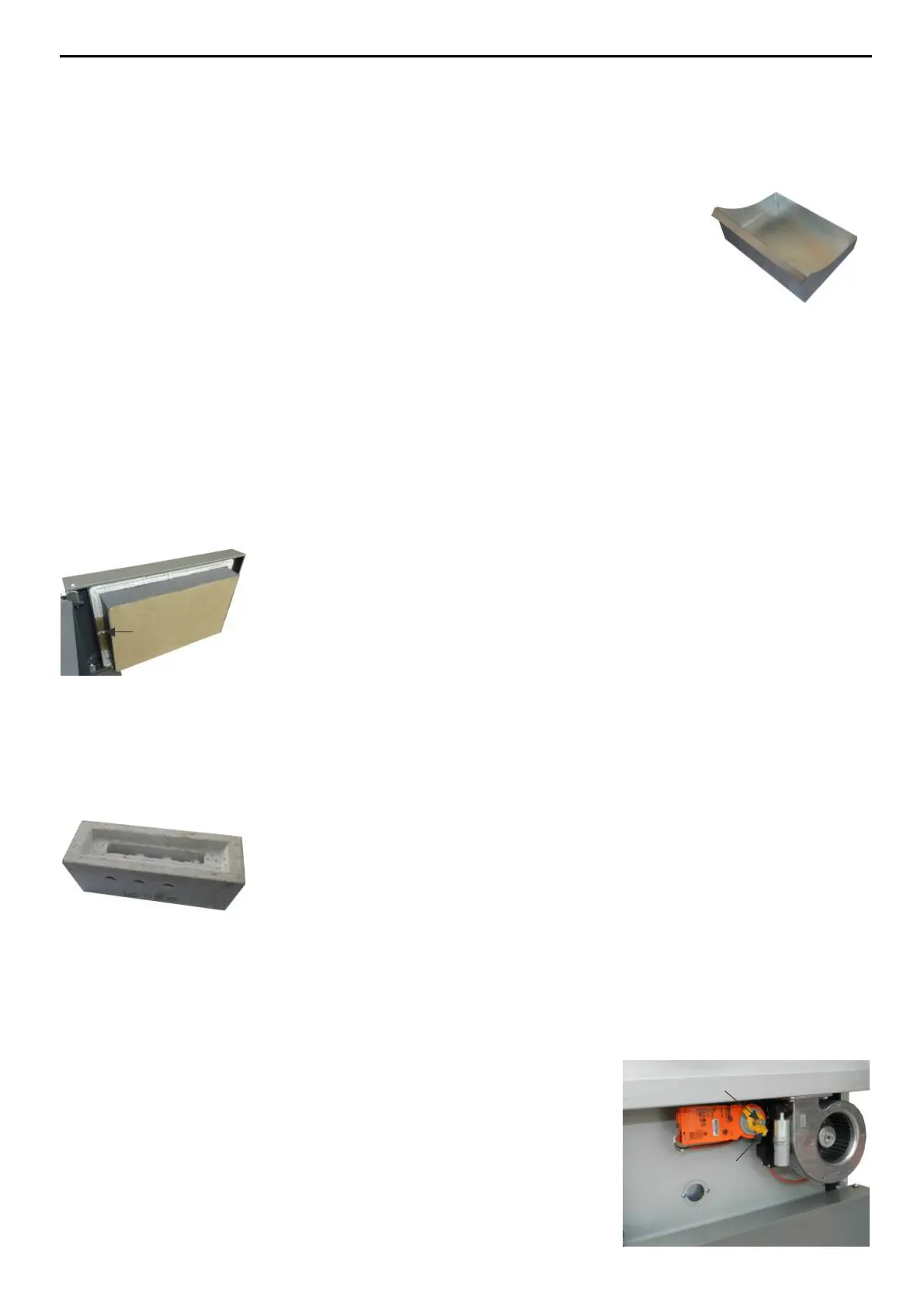

15.4 FLAP SERVO-UNIT POSITION SET UP FOR BOILER VIGAS

Lambda Control

25

Contractor provides regular checks and boiler maintenance. During operation is important to check water

pressure, door seals, chimney flap tightness, exchanger cover and seal, flue way staunchness and fan

performance.

WARNING :

Before boiler is shut down for summer season, clean combustion chamber properly, do not leave any

condensed moisture inside and open bottom door and chimney flap.

The boiler door are stabilized in 3 points – two rotary pins and door catch. If

door does not fit tightly, it is also possible to fix it from hinge side. Slightly turn

hinge to release and turn by hinge screw and then move door in desired

direction. To change gasket, spot „1“ points out the place, where gasket is

connected.

Heatproof nozzle is block made of heatproof concrete used to mix gases with

secondary air and so efficient burning is in progress. Nozzle is located on water

cooling rack. Nozzle is surrounded with heatproof concrete in the same height as

nozzle. Nozzle lifetimel, depends on mechanical damage during fuel adding or

poke the fire. Therefore, the nozzle is considered as spare part. Cracks on

nozzle are not reason to nozzle exchange, this is necessary only when nozzle

drops. If the nozzle is damaged, its necesary to remove bits and pieces of old

nozzle and then insert new nozzle int the hole. Check if new nozzle fits in the

hole.

When cleaning exchanger pipes (pic.3/24) make sure that flap area is clean, as well as flap itself.

(pic.3/16). Leakage can decrease boiler preformance.

Step 1: unplug line connector from power supply 230V/50Hz,

Step 2: loose screw „1“ with forked spanner,

Step 3: using spanner turn axle „2“ to maximum position anti-

clockwise, must turn easily!!! In the see-through „3“ window

check flap motion.

Step 4: tighten scew „1“

Step 5: plug connector line to power supply 230V/50Hz.

Correct position of servo-unit and flap to control primary and secondary air are most important condition of

burning process with minimum emissions. To position servo-unit and flap do as follows:

VIGAS UD29 boiler cleaning

If using brown coal as fuel, cleaning wil be same as wood designed only boiler. Clean fuel bunker with

cleaning flap (12) pic.3 and ashtray drawer as follows:

1. Open bottom door (15) pic.3, insert drawer and close the door.

2. Open cleaning flap and upper door (2) pic.5.

3. Use relevant accessory to pile up ash from fuel bunker area into drawer

4. Wait a moment, open bottom door, take out drawer and close the door.

ATTENTION:

Do not leave ashtray drawer inside the boiler VIGAS 29 UD during use.

Loading...

Loading...