Service Procedure

©2007 Viking Preferred Service 39

Charging

NOTE: Do not use captured or recycled refrigerant in

units. Captured or recycled refrigerant voids any

warranty.

NOTE: Charge system with exact amount of refrigerant.

Refer to unit serial plate for correct refrigerant

charge. Inaccurately charged system will cause

future problems.

To charge system:

Close valves “A” to vacuum pump and “C” to vacuum

gauge and “E” to low side manifold gauge.

1. Set scale on dial-a-charge cylinder for corresponding

HFC134a pressure reading.

2. Open valve “F” to charging cylinder and let exact

amount of refrigerant flow from cylinder into system.

Close valve.

Low side gauge pressure should rise shortly after

opening charging cylinder valve as system pressure

equalizes through capillary tube.

If pressure does not equalize, a restriction typically

exists at capillary/drier braze joint.

3. If pressure equalizes, open valve “E” to low side

manifold gauge and pinch off high side drier process

tube.

4. Start compressor and draw remaining refrigerant

from charging hoses and manifold into compressor

through compressor process tube.

5. To check high side pinch-off drier process tube.

Close valve “D” to high side gauge. If high side

pressure rises, repeat high side pinch-off and open

valve “D”. Repeat until high side pinch-off does not

leak.

6. Pinch-off compressor process tube and remove

charging hose. Braze stub closed while compressor

is operating.

7. Disconnect power. Remove charging hose and braze

high side drier process tube closed.

8. Recheck for refrigerant leaks.

Refrigerant Charge

Refrigerant charge in all capillary tube systems is critical

and exact amount is required for proper performance.

Factory charges are shown on serial plate.

NOTE: Do not use refrigerant other than shown on

serial plate.

HFC134a Service Information

HFC134a is alternative refrigerant for CFC12.

HFC134a has an ozone depletion potential (ODP) factor

of 0.0 and a global warming potential (GWP) factor of

0.27. HFC134a is not flammable and has acceptable

toxicity levels. HFC134a is not interchangeable with

CFC12. There are significant differences between

HFC134a and CFC12 which must be considered when

handling and processing refrigeration system.

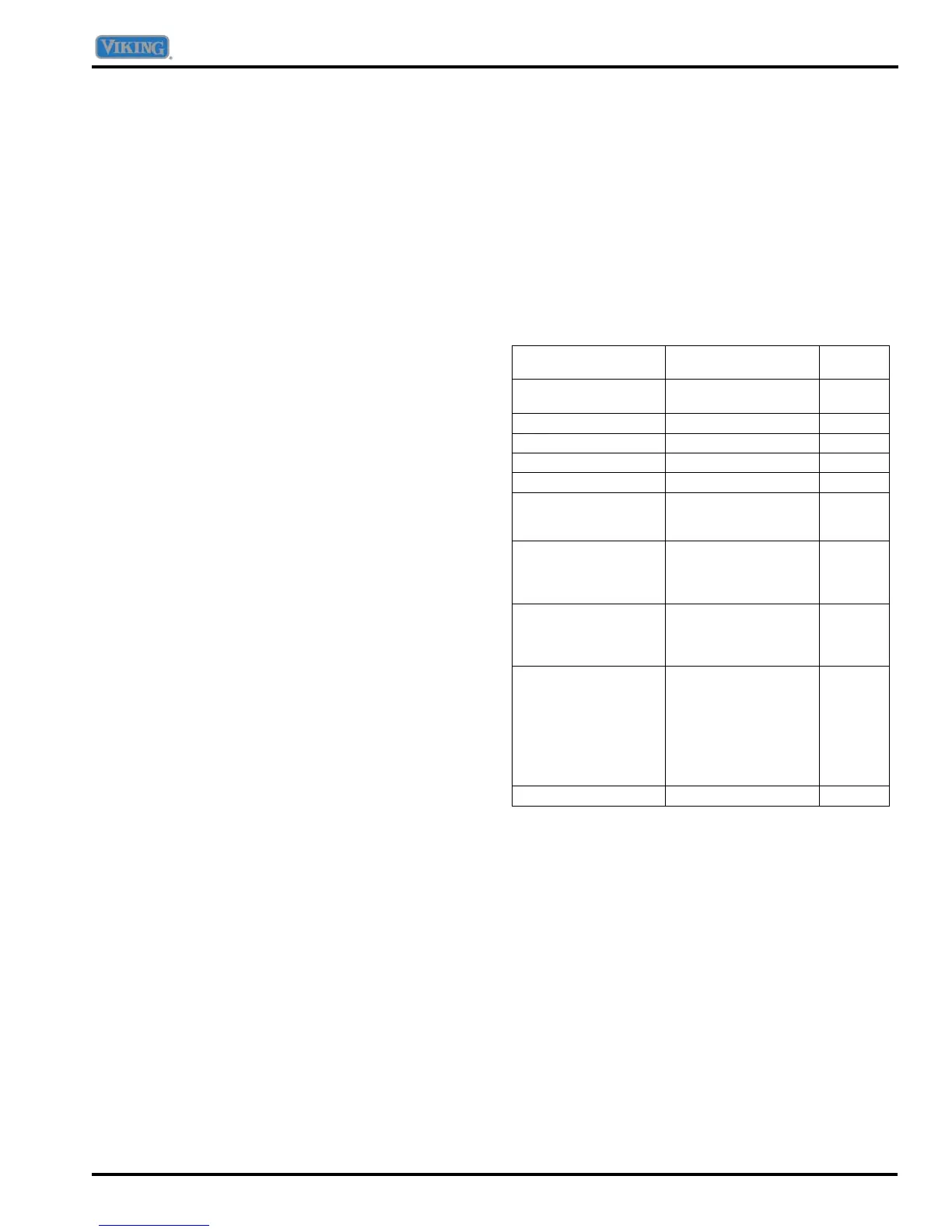

Health, Safety, and Handling

Health, safety and handling considerations for HFC134A

are virtually no different than those for CFC12.

Health, Safety, and

Handling

CFC12 HFC134a

Allowable overall

exposure limit

1,000 ppm Same

Vapor exposure to skin No effect Same

Liquid exposure to skin Can cause frostbite Same

Vapor exposure to eye Very slight eye irritant Same

Liquid exposure to eye Can cause frostbite Same

Above minimum

exposure limit

Can cause Asphyxiation,

Tachycardia, and Cardia

Arrhythmias

Same

Safety and handling Wear appropriate skin

and eye protection. Use

with adequate

ventilation.

Same

Spill management Remove or extinguish

ignition or combustion

sources. Evacuate or

ventilate area.

Same

Fire explosion hazards May decompose if

contact with flames and

heating elements.

Container may explode

if heated due to resulting

pressure rise.

Combustion products

are toxic.

Same

Disposal procedures Recycle or reclaim. Same

Loading...

Loading...