6 7

Installation

PRE-INSTALLATION

Below are the services required to be in place prior

to the installation of the Vivreau ViTAP Dispensing

System. If you have any questions regarding these

or other services, please contact Vivreau Service

Toll-Free at 877-999-1044.

WATER SUPPLY

A potable 1/2” cold water supply terminating in a

1/2” Ball Valve, 1/2” female pipe thread.

IMPORTANT ________________________

Ball Valve must be accessible for service

and installation.

Minimum Water Pressure: 50 PSI

Minimum Water Flow: 80 gallons per hour

IMPORTANT ________________________

The Vivreau ViTAP Dispensing System

incorporates backow prevention. Any additional

backow devices required by State or Local

Code must also be supplied by the customer

prior to installation. There must not be any

other Filters/Pre-Filters inline before the unit.

ELECTRICAL OUTLET

Model ViTAP-2

(1) 20 Amp Electrical Recepticle (NEMA 5-20R)

120V, 60 Hz (11 Amps)

Model ViTAP-2H

(2) 20 Amp Electrical Recepticle (NEMA 5-20R)

120V, 60 Hz (11 & 13 Amps)

Model ViTAP-1

(1) 20 Amp Electrical Recepticle (NEMA 5-20R)

230V, 60 Hz (11 Amps)

Model ViTAP-1H

(2) 20 Amp Electrical Recepticle (NEMA 5-20R)

230V, 60 Hz (11 Amps)

All outlets must be mounted high in the cabinet to

avoid accidental contact with water.

CO

2

CO

2

Cylinder (Customer supplied) - Size should be

selected based on available space.

NOTE: If connecting to a bulk or existing CO

2

system, a CO

2

line terminating at a 1/4” Barbed

Shutoff Valve must be available within 40” of the

unit with 100 PSI minimum pressure.

DRIP TRAY AND DISPENSING HEAD

CUTOUTS

Cut out the holes for the Drip Tray and Dispensing

Head per the supplied template.

NOTE: The Dispensing Head must be mounted

on the work surface directly above the Chiller/

Carbonator.

DRIP TRAY DRAIN

Drip Tray must be plumbed to a drain. Customer

will need to supply a drain according to State and

Local Codes. Drain must be at least 1-1/4” ID.

VENTILATION

If the system is to be installed in an enclosed

space or in a cabinet, adequate ventilation must

be provided. Ventilation must be at the top and

bottom of the enclosure for proper air ow.

Failure to provide adequate

ventilation will cause system failure.

This unit is to be installed indoors only.

LOCATION OF SERVICES

All services must be accessible for installation and

service. Ensure all services are kept within 40” of

the Vivreau ViTAP Dispensing System.

Water Shutoff Valve to be located at low level.

Ensure there is sufcient room for a 6” long tting to

be connected to the Water Shutoff Valve.

Top of drain should be located between 12” and

18” from oor level.

SHIPPING DAMAGE/MISSING PARTS

Unpack and inspect the unit for shipping damage

and/or missing parts. If any damage or missing

parts are found, contact Vivreau Service Toll-

Free at 877-999-1044 and report the missing or

damaged parts.

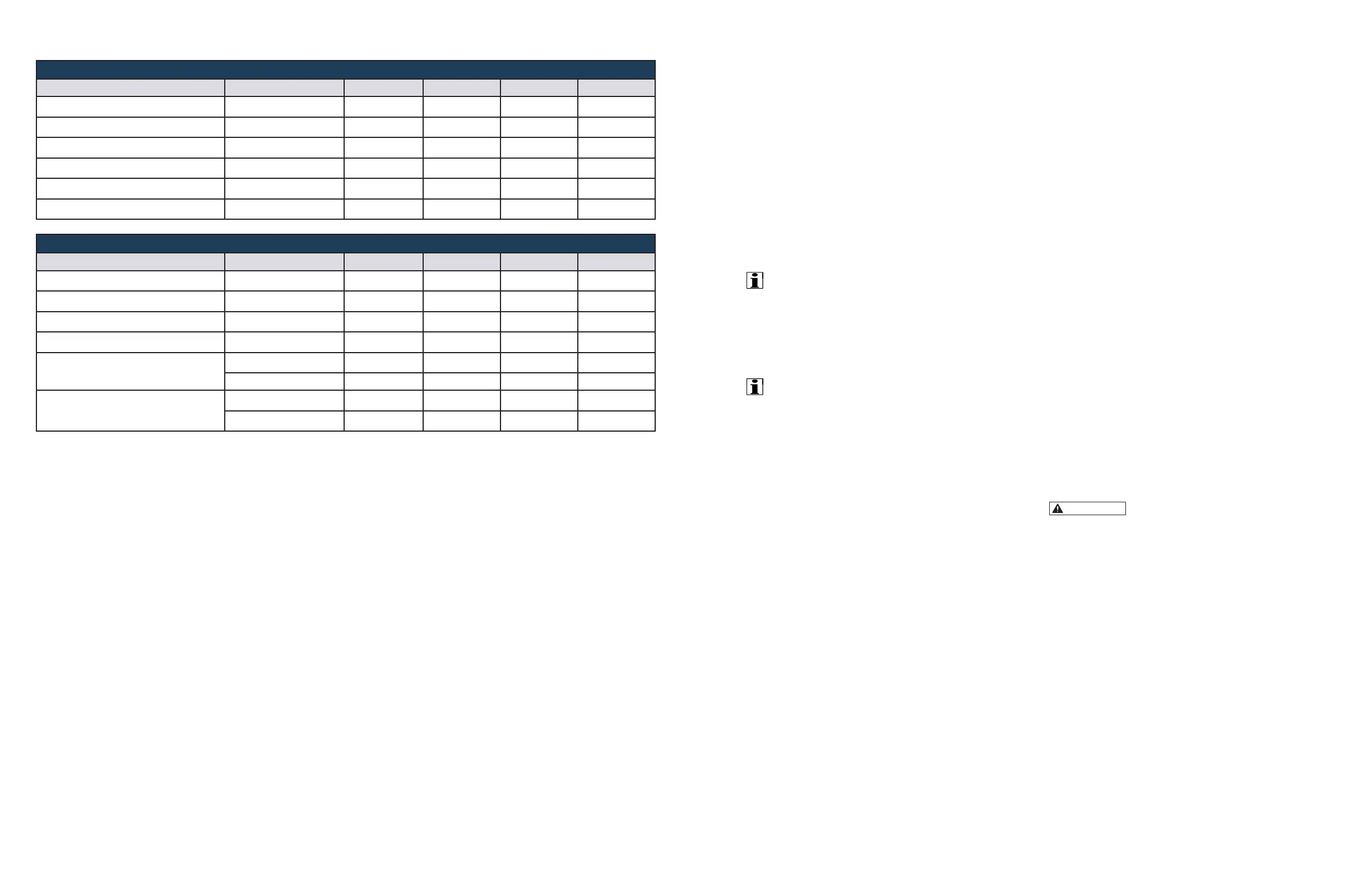

Cooler/Carbonator Specications

Description Specication ViTap-2 ViTap-2H ViTap-1 ViTap-1H

Width

15”

ü ü

8.25” 8.25”

Height

20”

ü ü

19” 19”

Depth

18.5”

ü ü

14" 14”

Weight

39.6 lb.

ü ü

44.6 lb 44.6 lb

Voltage

110/120 VAC/60 Hz

ü ü ü ü

Amperage

11A

ü ü ü ü

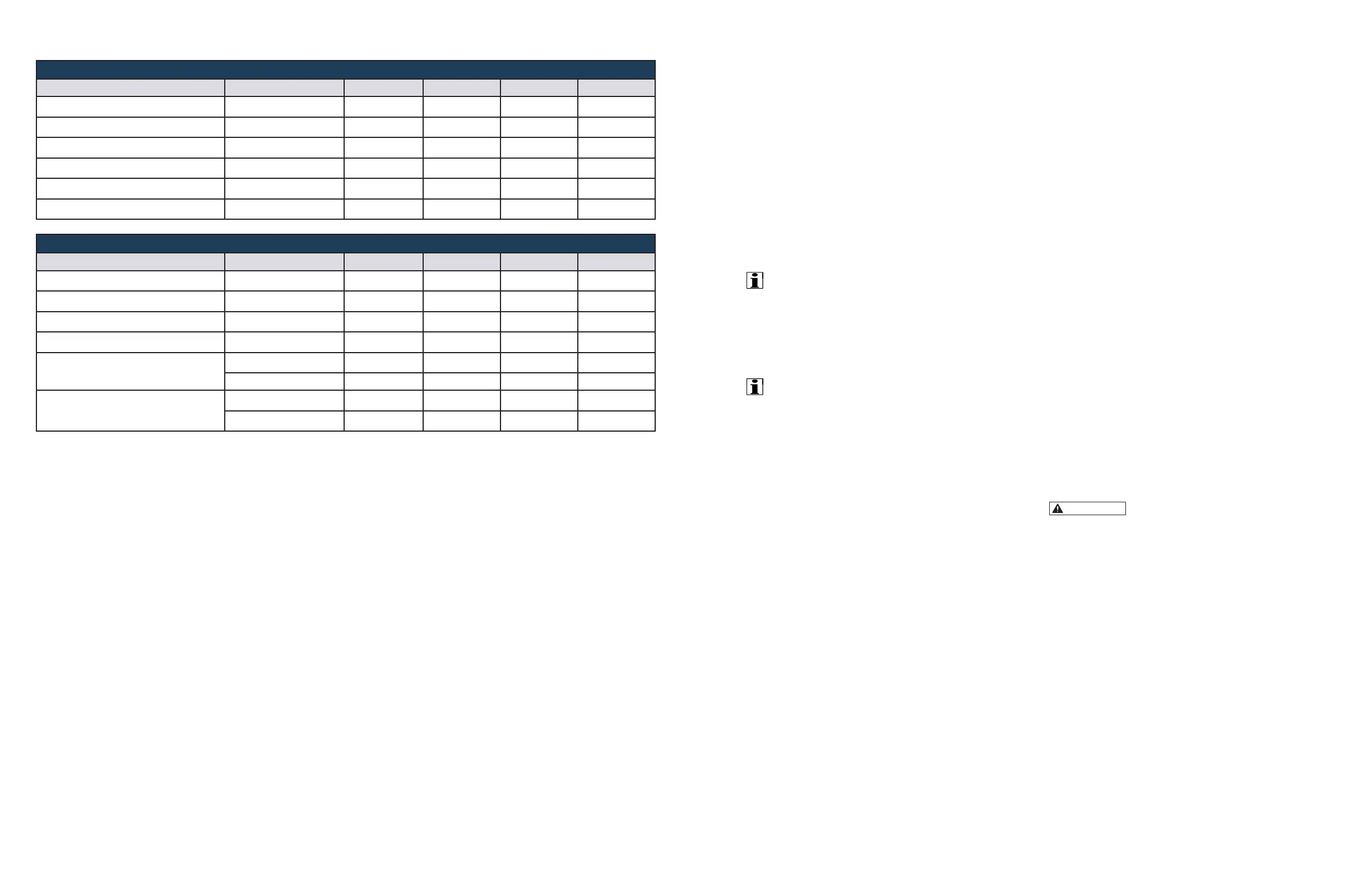

Boiler Specications

Description Specication ViTap-2 ViTap-2H ViTap-1 ViTap-1H

Width

5.25” NA

ü

NA 5.37”

Height

22” NA

ü

NA 21”

Depth

15.75” NA

ü

NA 15.62”

Weight

30.8 lb NA

ü

NA 18.2 lb

Voltage

110/120 VAC/60 Hz NA

ü

NA 120 V

230/240 VAC/60 Hz NA NA NA 240 V

Amperage

13A NA

ü

NA

ü

11A NA NA NA

ü

Loading...

Loading...