8 9

INSTALLER’S CHECKLIST

Below are the services required to be in place prior

to the installation of the Vivreau ViTAP Dispensing

System. Please review and check all services

before beginning work. If anything is missing or not

correct, do not start the installation. Call Vivreau

Service for instructions at 877-999-1044.

WATER SUPPLY

A potable 1/2” cold water supply terminating in a

1/2” Ball Valve, 1/2” female pipe thread.

IMPORTANT ________________________

Ball Valve must be accessible for service and

installation.

Any water line or valve less than 1/2” is not

acceptable. Must be a direct supply with no

other Inline Filters.

ELECTRICAL OUTLET(S)

All Electrical Outlets must be within 40” of unit. No

Extension Cords.

Model ViTAP-2

Chiller/Carbonator

20 Amp Electrical Recepticle (NEMA 5-20R)

120V, 60 Hz (11 Amps)

Model ViTAP-2H

Chiller/Carbonator

20 Amp Electrical Recepticle (NEMA 5-20R)

120V, 60 Hz (11 & 13 Amps)

Boiler

20 Amp Electrical Recepticle (NEMA 5-20R)

120V, 60 Hz (11 & 13 Amps)

Model ViTAP-2HD

Chiller/Carbonator

15 Amp Electrical Circuit (NEMA 5-15) 120V, 60

Hz

Boiler

20 Amp Electrical Circuit (NEMA L6-20) 230V, 60

Hz

Model ViTAP-1

Chiller/Carbonator

20 Amp Electrical Recepticle (NEMA 5-20R)

230V, 60 Hz (11 Amps)

Model ViTAP-1H

Chiller/Carbonator

20 Amp Electrical Recepticle (NEMA 5-20R)

230V, 60 Hz (11 Amps)

Boiler

20 Amp Electrical Recepticle (NEMA 5-20R)

120V, 60 Hz (11 & 13 Amps)

CO

2

CO

2

Cylinder (Customer supplied) must t within

the allotted space.

CO

2

Cylinder must always remain vertical.

If connecting to a bulk or existing CO

2

system, a

CO

2

line terminating at a 1/4” Barbed Shutoff Valve

must be available within 40” of the unit with 100

PSI minimum pressure.

DRIP TRAY AND DISPENSING HEAD

CUTOUTS

Cut out the Holes for the Drip Tray and Dispensing

Head per the template.

The Dispensing Head must be mounted on the

work surface directly above the Chiller/Carbonator.

The Dispensing Head lines must never be

extended.

DRIP TRAY DRAIN

Drip Tray must be plumbed to a drain. Customer will

need to supply a properly trapped drain according

to State and Local Codes. The drain must be large

enough to accommodate a 1” OD exible pipe.

VENTILATION

If the system is to be installed in an enclosed

space or in a cabinet, adequate ventilation must

be provided. Ventilation must be at the top and

bottom of the enclosure for proper air ow.

Failure to provide adequate

ventilation will cause system failure.

This unit is to be installed indoors only.

INSTALLATION

IMPORTANT ________________________

Installation must be performed by properly

trained and qualified persons and comply with

Federal, State Local Codes for connection

to electrical supplies, water supplies and

pressurized gas systems.

Note: Vivreau cannot be held responsible for any

damage caused by improper installation.

LOCATION

A completed Pre-installation Checklist must be

available prior to installation. The Vivreau ViTAP

Dispensing System must be installed indoors

where the ambient air temperature will not exceed

90°F.

The Vivreau ViTAP Dispensing System should not

be exposed to spills, spray, steam or high humidity.

A suitable location should be chosen within 40” of

the electrical and water supply connections.

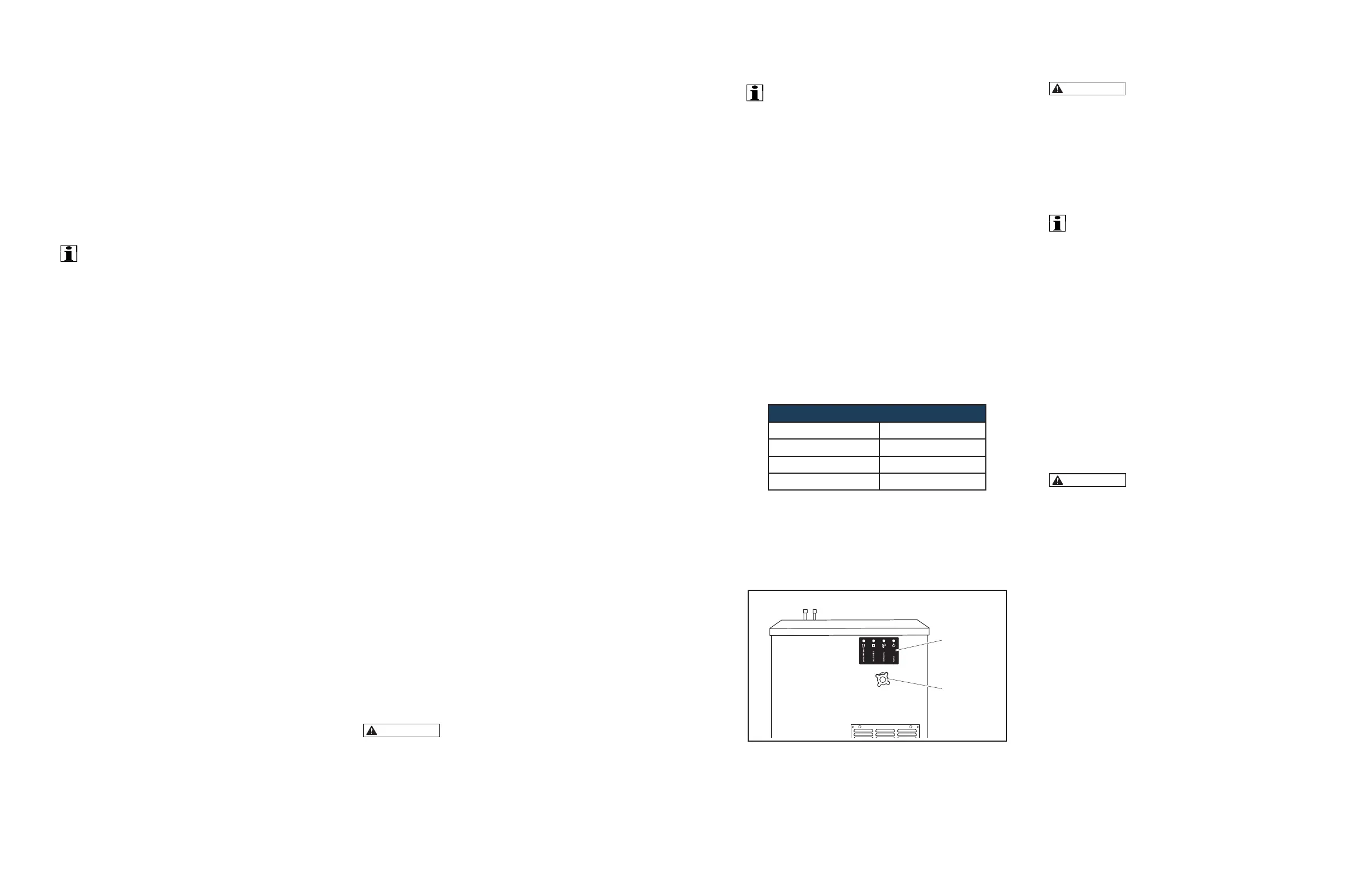

Installation Clearance for Chiller Unit

Left side 2”

Right side 2”

Rear 2”

Above Open

Do not obstruct air vents.

Install the system on a rm, level oor or base.

Chiller/Carbonator should be installed with LED

Panel and Overow Drain Tube facing out for

visibility and ease of access.

CONTROL PANEL FACING FRONT

LED Panel

Overflow

Drain Tube

Plug

LED Panel and Overow Drain Tube Plug Location

CONNECTIONS

This appliance must be

electrically grounded.

ELECTRICAL

Power Supply: 120V 60Hz

Power Supply Connection Type: NEMA 5-20

Grounded, with proper circuit protection.

IMPORTANT ________________________

When a Carbonator is used – follow the

Carbonator’s installation instructions.

CO

2

Mount the CO

2

Regulator in a secure location

where it will not be subject to damage.

A Cylinder of food-grade CO

2

gas is required. Only

use non-syphon type Cylinders.

NOTE: Before connecting, with the Cylinder Outlet

turned away, open Valve for short blast and close

immediately. This will clear any debris from the

outlet.

CO

2

Cylinder must be installed vertically and

secured with a Chain, Strap or Bracket.

CO

2

Cylinders should always be

secured in the vertical position with the Outlet

Valves positioned at the top. This will help

prevent injury caused by the entry of liquid

Carbon Dioxide into the Pressure Regulator.

Loading...

Loading...