10 11

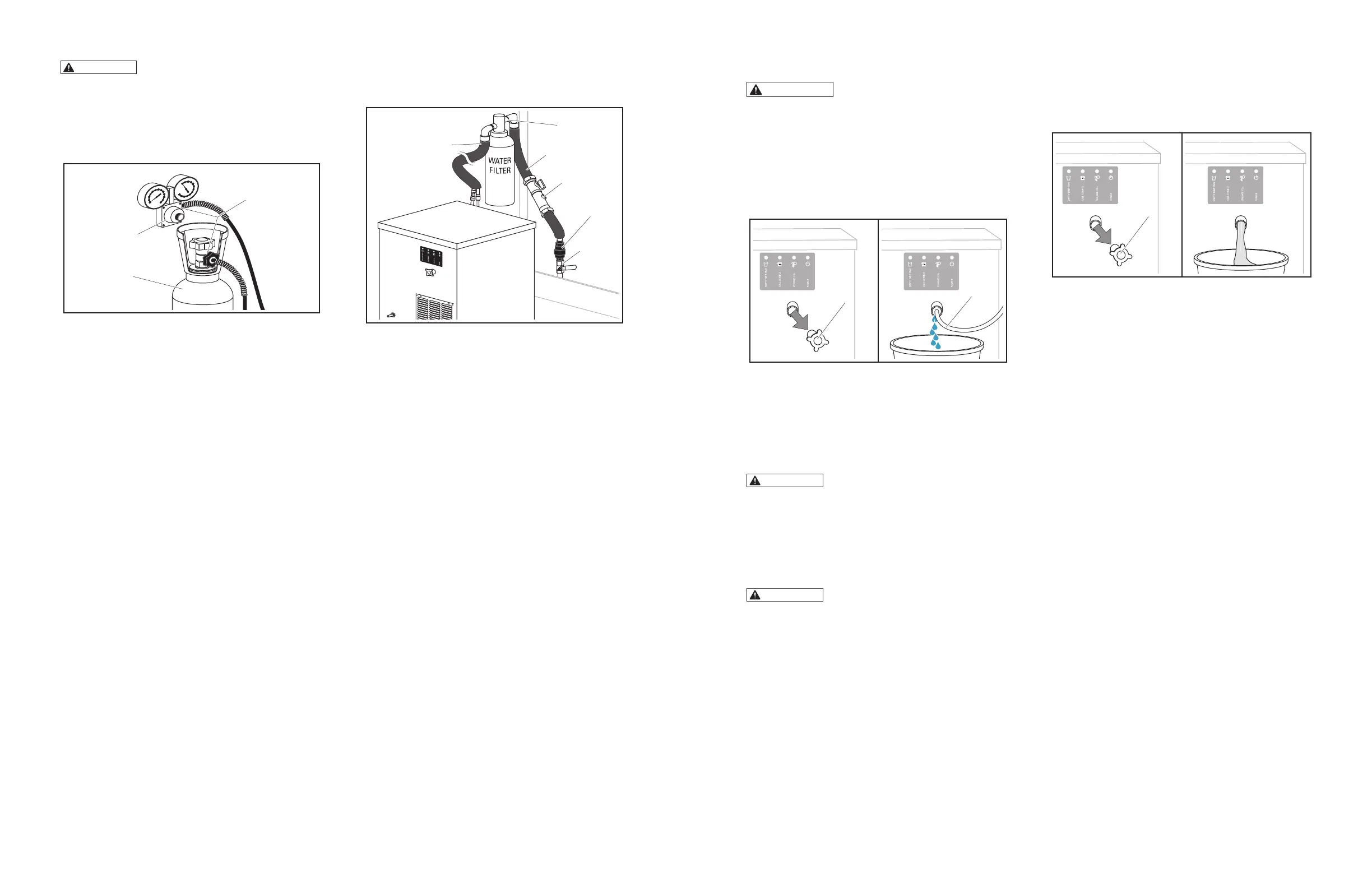

Never open the Gas Cylinder

Dispensing Head without the Gas Regulator

installed.

Ensure the Sealing Washers are positioned

between the Gas Regulator / Regulator Hose and

Cylinder and connect the Cylinder.

Regulator

Sealing

Washers

CO2 Cylinder

Sealing Washer Locations

Connect the Regulator to the unit using the supplied

Installation Kit. Tighten all connections.

In the event of a CO

2

leak, close the Cylinder Valve,

retighten connection(s) and retest. If leak persists,

report leak to Vivreau.

CO

2

Pressure: 65 – 70 PSI. Adjust Regulator as

needed.

WATER

The Vivreau ViTAP Dispensing System provides

backflow prevention, however, it must be installed

with adequate backflow protection to comply

with applicable Federal, State and Local Codes.

Additional backflow prevention must be installed

prior to connecting the unit to the water supply.

The water supply to the unit must be cold, potable

water with an accessible Shutoff Valve.

Water Inlet connection to the unit is 3/8” tube. A

Retaining Clip must be used to attach the tube

within the connection on the unit.

Insulate the pipe to prevent condensation.

The supply water pressure must be 50 PSI minimum

with a minimum ow of 1.5 gal/min. A Booster Pump

(for low pressure) or Pressure Regulator (for high

pressure) may be required to ensure the pressure.

1/2"

Shutoff

Valve

Water

Block

Insulate Pipe

Dual Check

Valve

3/8"

Connection

To

Chiller/

Carbonator

Water Connections

WATER BLOCK

A device called a Water Block (supplied by

Vivreau), must be installed between the Water

Supply Shutoff Valve and the Water Inlet to the unit.

This device is normally open but will close

automatically after it senses a continuous ow of

about 1.5 gallons.

UNDER-COUNTER INSTALLATION

The Under-Counter Chiller/Carbonator System

is intended to be located directly under the

Dispensing Head.

The Drip Tray is positioned in the counter under

the Dispensing Head and should have lateral play

of no more than 1/8”.

Dispensing Head Connection Tubes are to be

connected to the Under-Counter System directly

using the Installation Kit supplied by Vivreau.

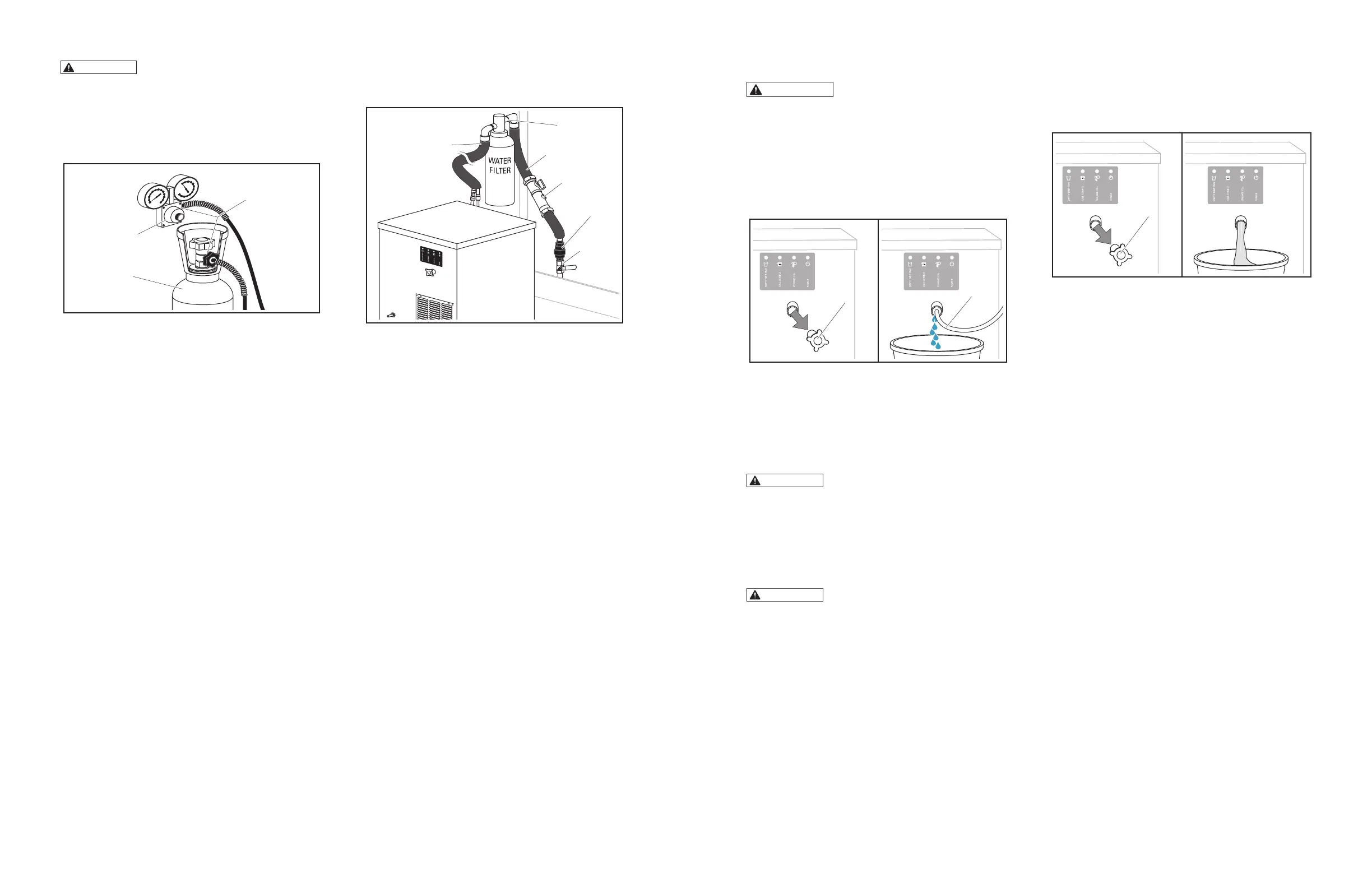

FILLING THE WATER TANK

Disconnect unit from electrical

power supply.

Before making the nal water connection to the unit:

Remove the Overow Plug on the front of the unit.

Prop the back of the unit up about 1”.

Slowly ll the Water Tank using the Water Supply Line.

Catch any water that overows.

Remove

Overflow

Drain

Tube Plug

Water

Supply

Line

Drain Overow

Level the unit.

Replace the plug.

Connect Water Supply Line to unit.

Clean up any spills.

Do not leave the Water Hose

unattended while filling.

Make sure no water spills onto electrical

components.

Unless approved by Vivreau, do not use

de-ionized water or add any substance to the

water.

The installer must stay on site

until a full icebank has formed. Water will be

displaced and exit from the overflow.

OVERFLOW

The Overow Drain will pass water displaced by the

formation of the icebank on initial thermal pulldown.

This water must be collected and drained.

Remove

Overflow

Drain

Tube Plug

Remove Overow Drain Tube Plug

Remove the Overow Drain Tube Plug and catch

any water draining from the Overow Tube.

Replace plug.

BOILER INSTALLATION

Vi Tap-2H and Vi Tap-1H

Electrical Installation:

Connect to 110-120 VAC Circuit with a NEMA

5-20 Plug.

This unit must be connected to a Grounded Outlet.

Refer to Rating Plate for further electrical

information.

Loading...

Loading...