ENGLISH

9.4. Maintenance

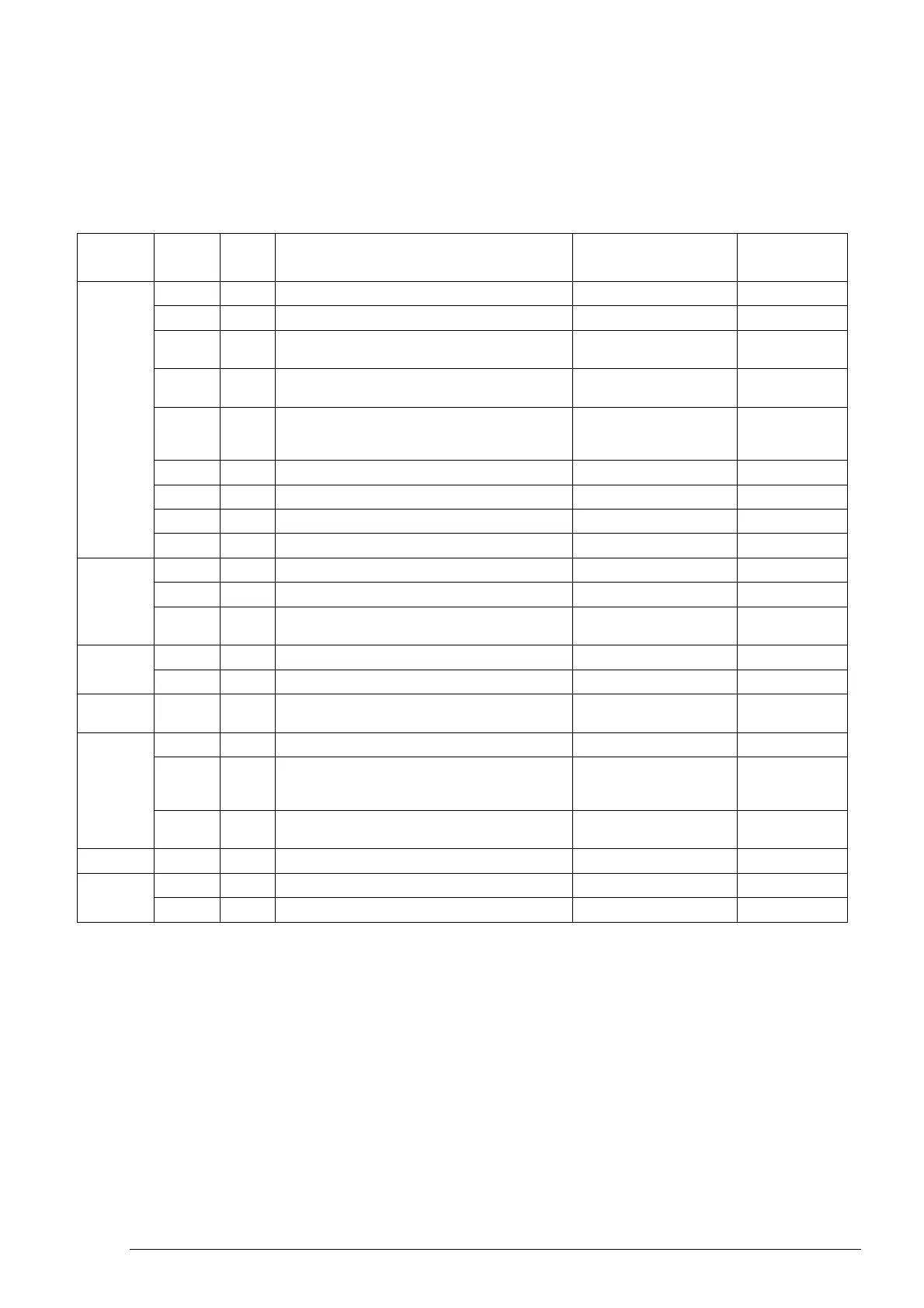

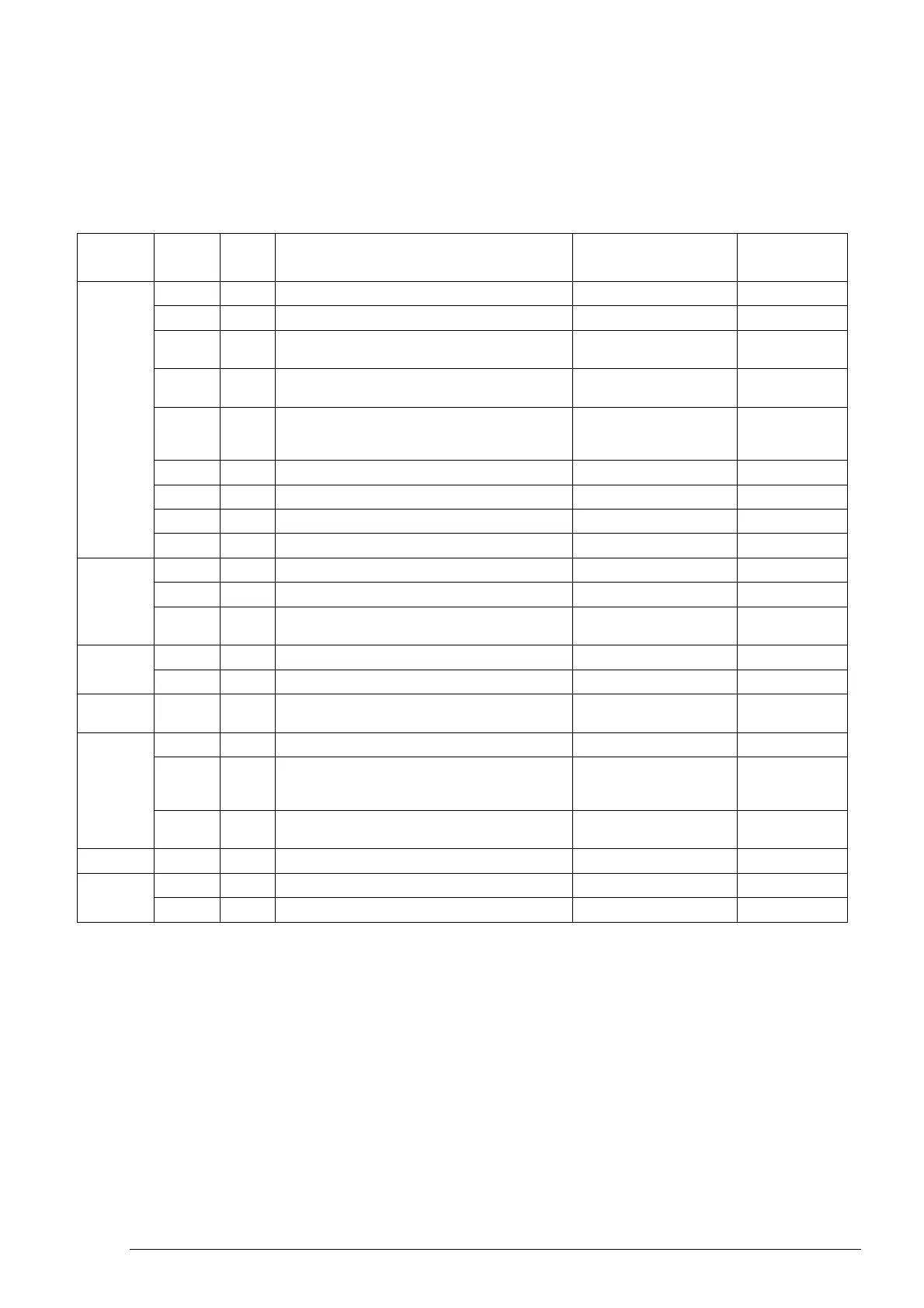

The table below indicates the Person Responsible for each procedure.

O = Operator

T = Trained Personnel.

Interval Person

Resp.

Key Description Procedure Lubricant/Fluid

Daily O 1 Pad(s) Check, flip or replace

O 1 Brush(es) Check, clean

O 6 Squeegee Clean, check for damage

and wear

O 8 Scrub head skirt Check for damage and

wear

O 2 Recovery tank Drain, rinse, clean float

shut-off screen and debris

tray

O 3 Solution tank Drain, rinse

O 4 Severe Environment tank (option) Check, refill CAD

O 5 Automatic battery watering tank (option) Check, refill DW

O 7 Batteries Charge if necessary

Weekly O 7 Battery cells Check electrolyte level DW

O 7 Battery compartment Check for liquid

O 6 Squeegee assembly drip trap reservoir (dual disk

model)

Check. Clean

50 Hours O 2 Recovery tank lid seal Check for wear

O 9 Solution tank filter Remove and clean

100 Hours O 7 Battery watering system (option) Check hoses for damage

and wear

200 Hours O 7 Batteries, terminals and cables Check and clean

T 13 Steering chain Lubricate, check tension,

and check for damage and

wear

GL

T 14 Steering cable Check tension, Check for

damage and wear

750 Hours T 10 Vacuum motor Replace carbon brushes

1250

Hours

T 11 Propel motor Replace carbon brushes

T 12 Brush motor(s) Replace carbon brushes

LUBRICANT/FLUID

DW Distilled water

CAD Commercial approved detergent

GL SAE 90 weight gear lubricant

Loading...

Loading...