Valvole brevettate per compressori rotativi a vite e pistoni

Patented valves for piston and screw rotary compressor

V.M.C. s.p.a. Via Palazzon 35 – 36051 Creazzo (VI) – ITALY

Internet www.vmcitaly.com - Phone +390444/521471 +390444/341115 - Fax

TIPO

TYPE

REVISIONE

REVISION

DATA

DATE

GRUPPO

LINE

ARTICOLO

ARTICLE

MODELLO

MODEL

Pagina 38 di 43

6.2 TIPS FOR THE STARTING PHASE

After carrying out the topping-up operations for the Pack Smart, start the machine and switch it off

after 2 seconds at the latest so as to load some air.

The machine will not load air, if the air-end shaft does not turn in the right direction as indicated by

the arrow on the case (see point 5.1 in the Runbook).

If the direction of shaft rotation is not correct, you have to act on it through the motor electrical

connections (see chapter 5.1).

Start the machine again if you want to check the right direction of rotation.

The direction of shaft rotation can be checked as follows:

- For belt drive, check the direction of pulley rotation. It must be the same as the direction

indicated by the arrow on the air-end case.

- For spring drive, check the rotation direction of flexible coupling through the slits of bell

housing. The direction of rotation of flexible coupling must be the same as the rotation

indicated by the arrow on the air-end case.

- For gearing drive, check the rotation direction of the electric motor cooling fan. It must be

the other way round compared to the arrow on the air-end case.

6.3 LONG PERIODS OF INACTIVITY OF THE PACK SMART

If during the life of the compressor there are long periods of inactivity of the same (> 1 week) we

recommend to start the machine for about 5 minutes in idle mode. This will allow an optimal

lubrication of the system.

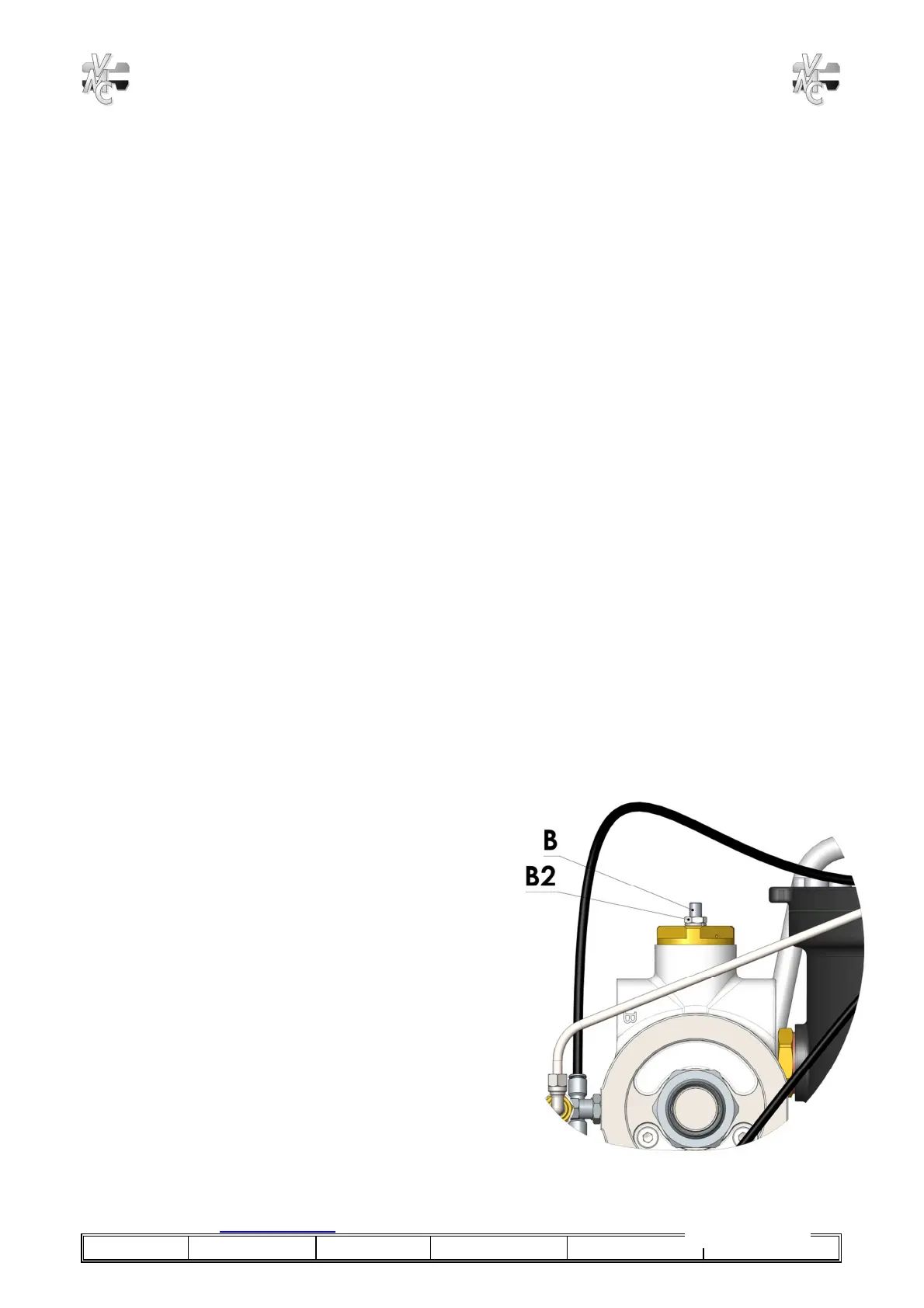

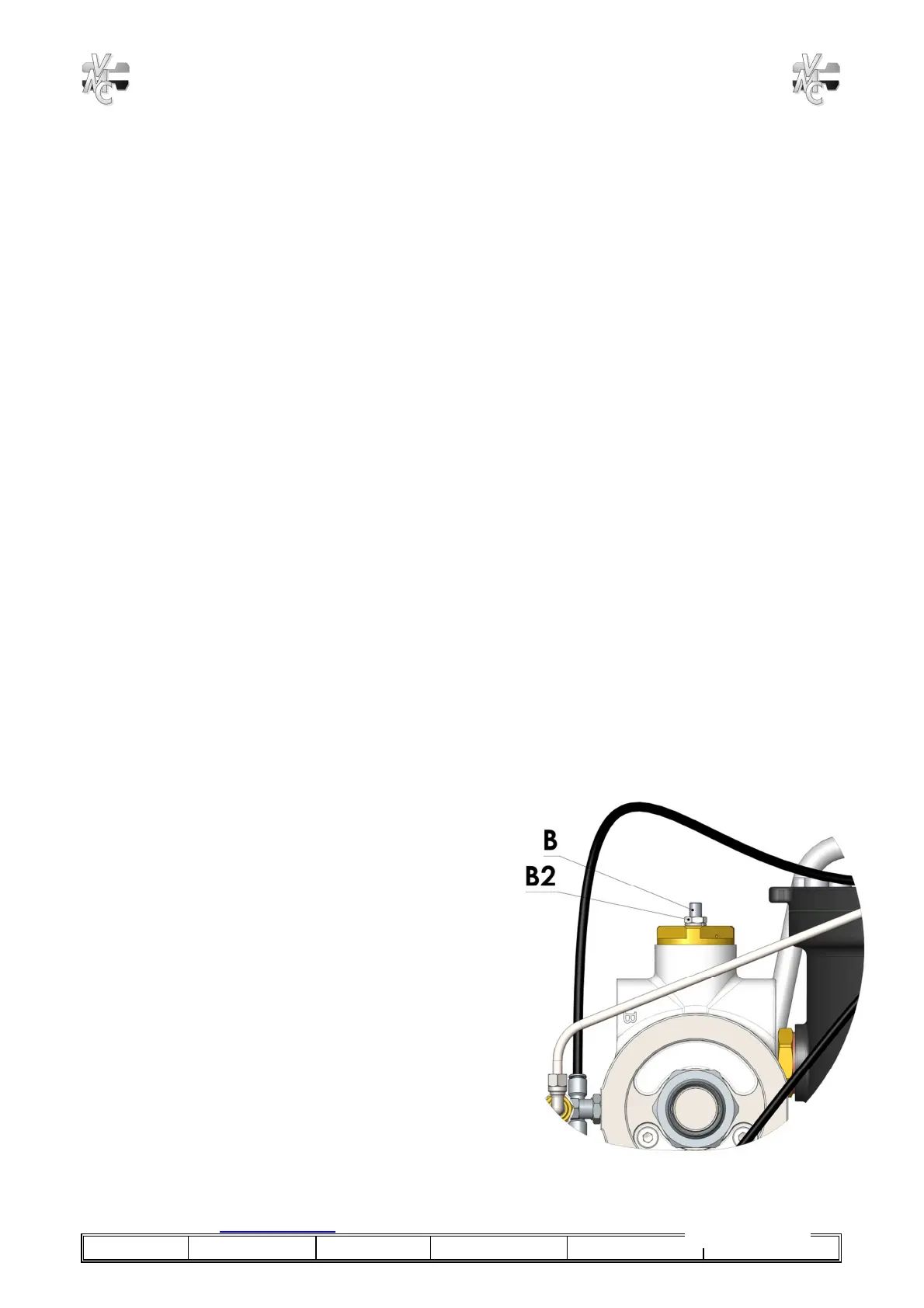

6.4 INSTRUCTIONS TO FOR A MINIMUM PRESSURE VALVE

CALIBRATION

IF YOU WANT TO INCREASE THE

CALIBRATION OF A MINIMUM PRESSURE

VALVE:

Unscrew the stop nut (B2) and screw the pressure

control screw slowly (B). When you reach the

desired pressure, screw the stop nut (B2) so that

the result is fixed (picture 11)

IF YOU WANT TO DECREASE THE

CALIBRATION OF A MINIMUM PRESSURE

VALVE:

Unscrew the stop nut (B2) and unscrew the

pressure control screw slowly (B). When you reach

the desired pressure, screw the stop nut (B2) so

that the result is fixed. (

picture 11)

Picture 11

Loading...

Loading...