Group

21 Reeondition

ing

engine

Cylinder head, e/eaning, inspeet

ion

(

=

,

..

St

e

llit

e

131

!i5O

1319

1.7-2.3 rnm

(Ö

.

Ö5;2_~

.

~749l!!}

'lG

n-

~~

(O

.

0670-0

.

0906

in)

"'

T"4

_5_

•.

~~

I

~~~~

i

~

11

9 861

In

let

Exheust

46

E

27

Tap valva

saa

t in

sa

rt

i

nto

cylinder

head

This operation

must

be carried

out

very

quickly,

with

in

3- 4 seconds to avoid temperature loss.

E28

Check

seat

fit

If seat

is

not secure, oversize

sea

t

mu

st

be

used.

After

replacing valve seat,

leat

must

be

ground

and valves

ground

-in.

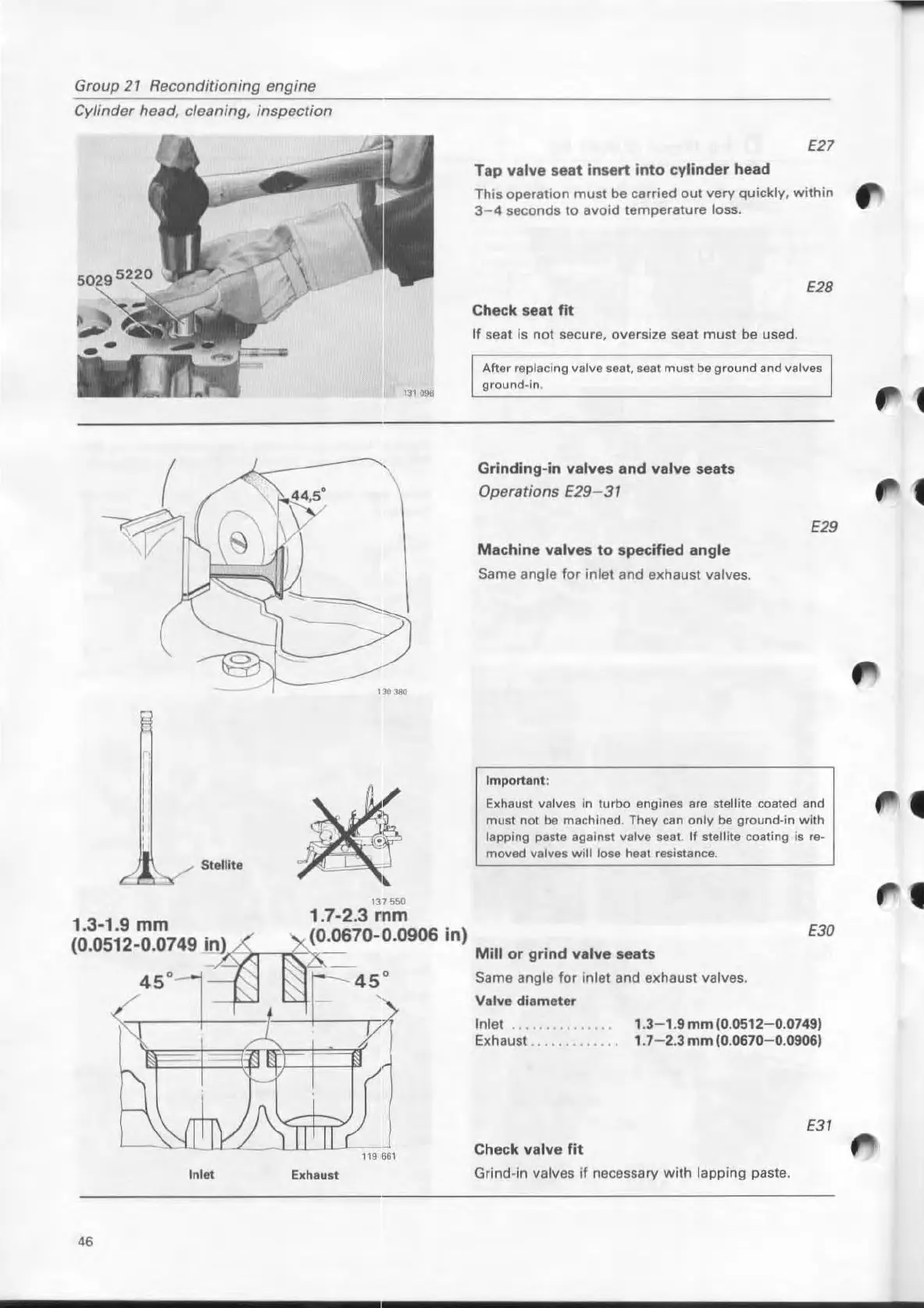

Grinding-in valves

and

valve

seats

Operations E29-

37

Machine valves

to

specified

angle

Same angle

for

inlet and exhaust valves.

Importent

:

E29

Exhaust

va

lves

in

turbo

engines are stellite coated and

must

not

be machined. They

ca

n

on

ly

be

ground-in

wi

th

lapping paste against valve seat.

If

stellite coating is re-

moved

valves

will

lose heat resista nce.

Mill

or

grind valve

seats

Same angle

for

in

let and exhaust valves.

Valve

di

a

meter

E

30

Inlet

Exhaust .

1.3- 1.9

mm

(0.0512- 0.0149)

1.7- 2.3

mm

(0

.0670- 0.0906)

E31

Check valve fit

Grind-in valves if necessary with lapping past

e.

1

Loading...

Loading...