UH

1

L

L

,

129

4S3

•

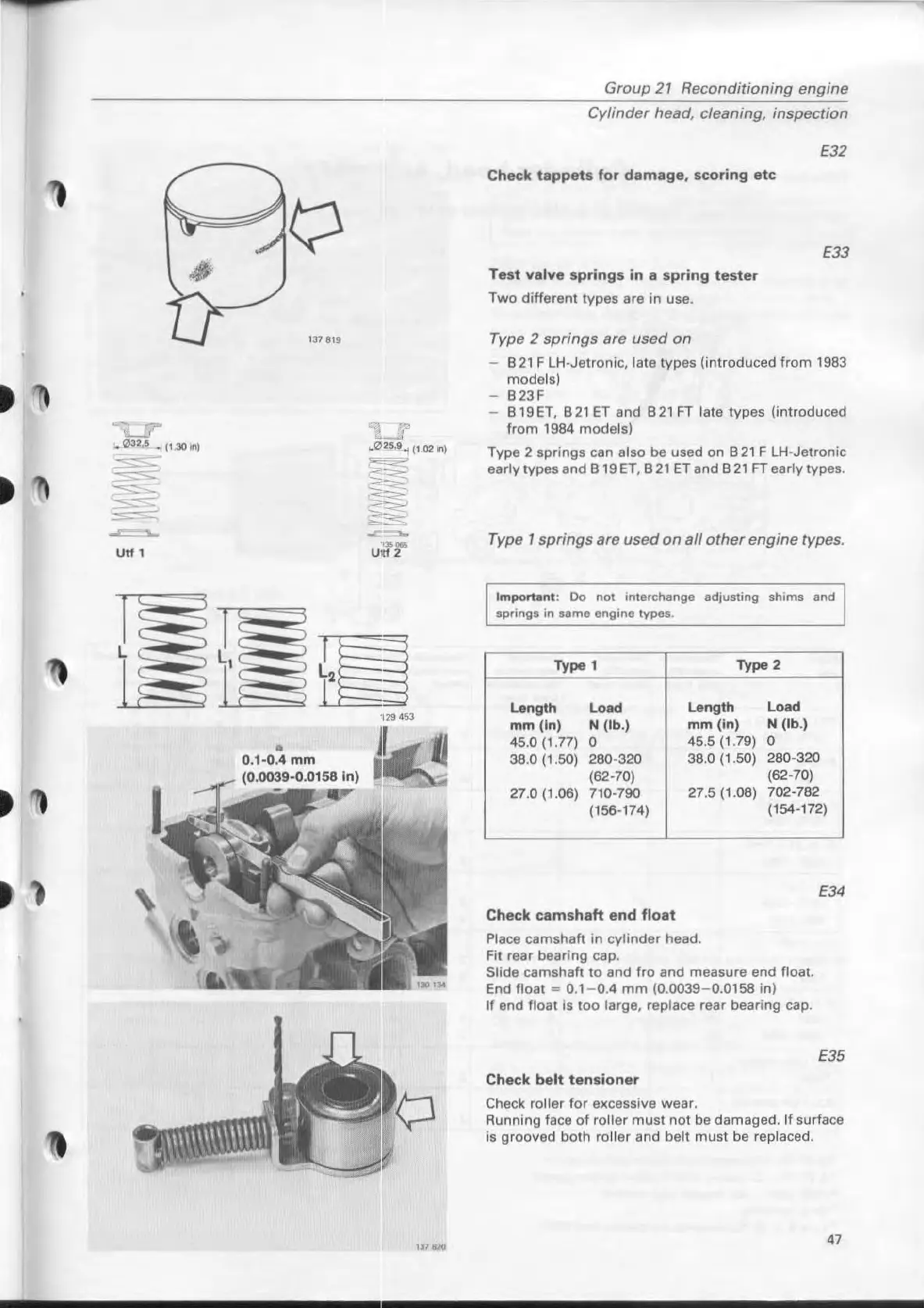

0.1-0.4

mm

(0.0039-0.0158 In)

Group

27

Reconditioning

engine

Cylinder

head, cleaning, inspection

Check

tappets

for

damage,

scoring

etc

Test valve

springs

in a spring

tester

Two

different types are in use.

Type 2

springs

are

used

on

E32

E33

B

21

F

LH

·Jetronic, late types (introduced

from

1983

modeis)

823

F

B

19

ET,

B

21

ET

and B

21

FT

late types (introduced

from

1984 modeis)

Typa 2 springs can also be used on B

21

F LH·Jetronic

early

types and B

19

ET,

B

21

ET

and B

21

FT

early types.

Type 1

springs

are

used

on

all

other

engine

types.

Import.nt:

Do

not

interchange

adjusting

shims

and

springs

in

same

engine

types.

Type1

Type 2

Length Load

Length

Load

mm (in) N

(Ib.)

mm

(in)

N (Ib.)

45.0 (1.77) O

45.5 (1.79) O

38.0 (1.50)

280-320

38.0

(1.50)

280-320

(62-70)

(62-70)

27.0 (1.06) 710-790

27.5 (1.08)

702-782

(156-174)

(154-172)

E34

Check

camshaft

end

float

Place camshaft

in

cylinder

head.

Fit rear bearing cap.

Slide camshaft

to

and

fro

and measure end float.

End

floal - 0.1- 0.4

mm

(0.0039-0.0158 in)

If end float is

100

large, repiace rear bearing cap.

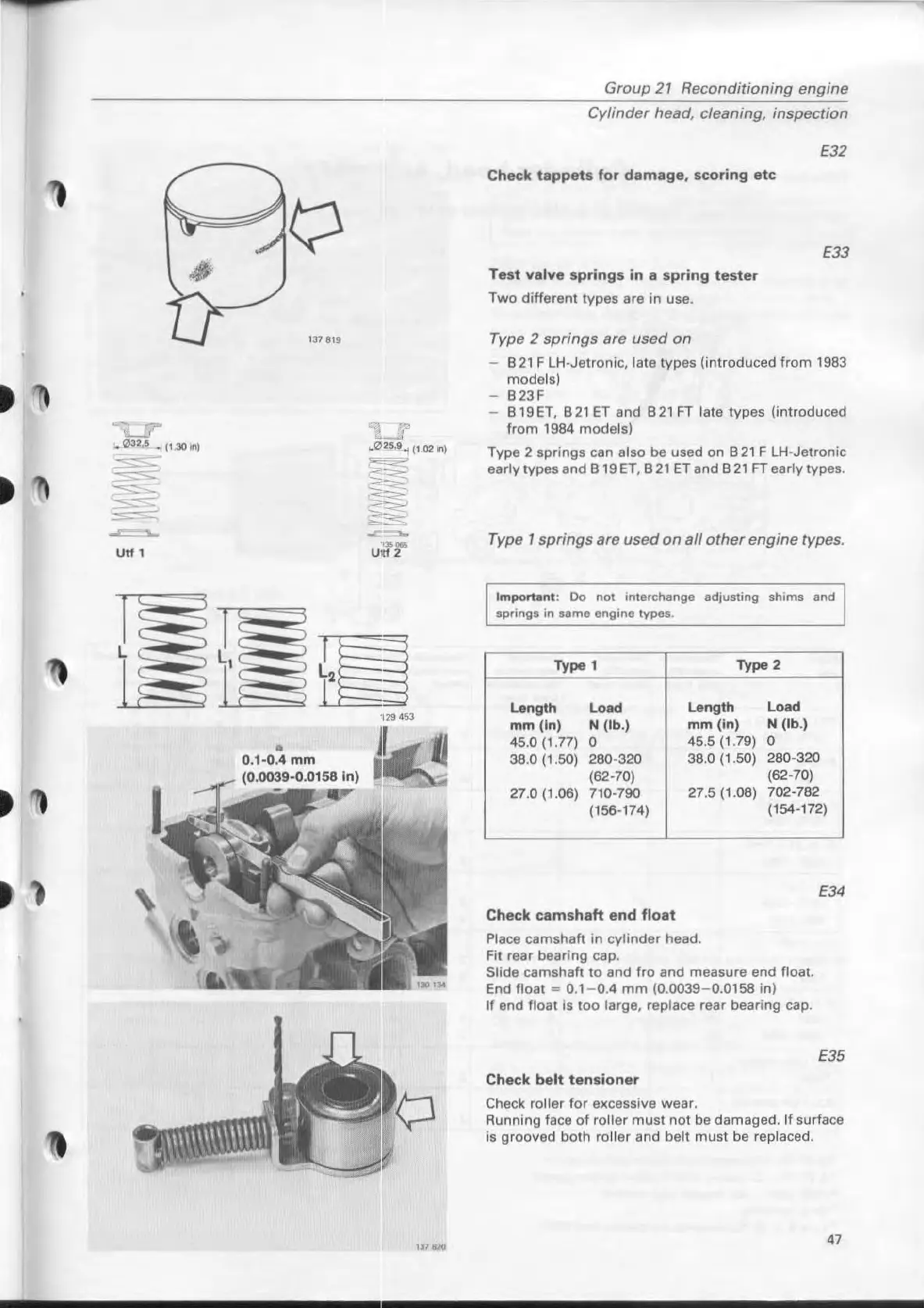

Check

belt

tensioner

Check roller

for

excessive wear.

E35

Running face

of

roller

must

not be dam

ag

ed.

If surface

is

grooved both roller and belt

must

be replaced.

47

Loading...

Loading...