1 Swing the superstructure to the side and raise

the track by using boom down operation and

dozer blade operation. For this movement,

operate the lever slowly.

2 Turn the track slowly in forward and reverse

direction several time. Stop the track while

moving in the reverse direction.

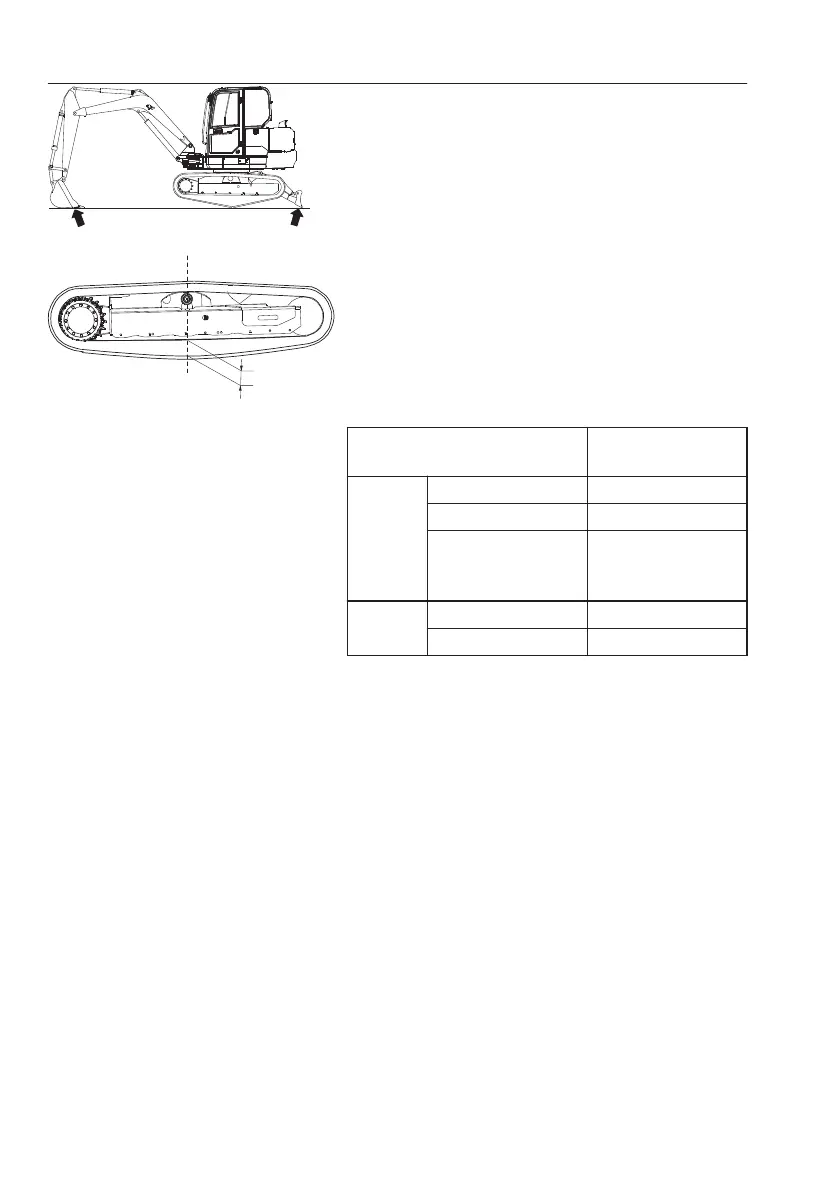

3 Measure the track slack (L) at the center of track

frame, the clearance between the bottom of

track frame and the upper surface of track shoe.

4 Adjust the track tension according to the soil

characteristics.

For more information, see page

287

.

Recommended track tension is as below,

Working condition Clearance ( L)

(mm) (in)

Steel

shoe

General soil 130-140 (5.1-5.5)

Rocky ground 120-130 (4.7-5.1)

Moderate soil like

gravel, sand,

snow, and so on.

140-150 (5.5–5.9)

Rubber

shoe

Rubber track type 63-73 (2.5–2.9)

Rubber pad type 130-140 (5.1-5.5)

1 Bottom side of frame

2 Upper side of shoe

266

Maintenance

Maintenance service, every 50 hours

Loading...

Loading...