Maintenance

12.3 Maintenance work

48

Operator’s manual | AS | 5100056974 | 06/2020 | [us]

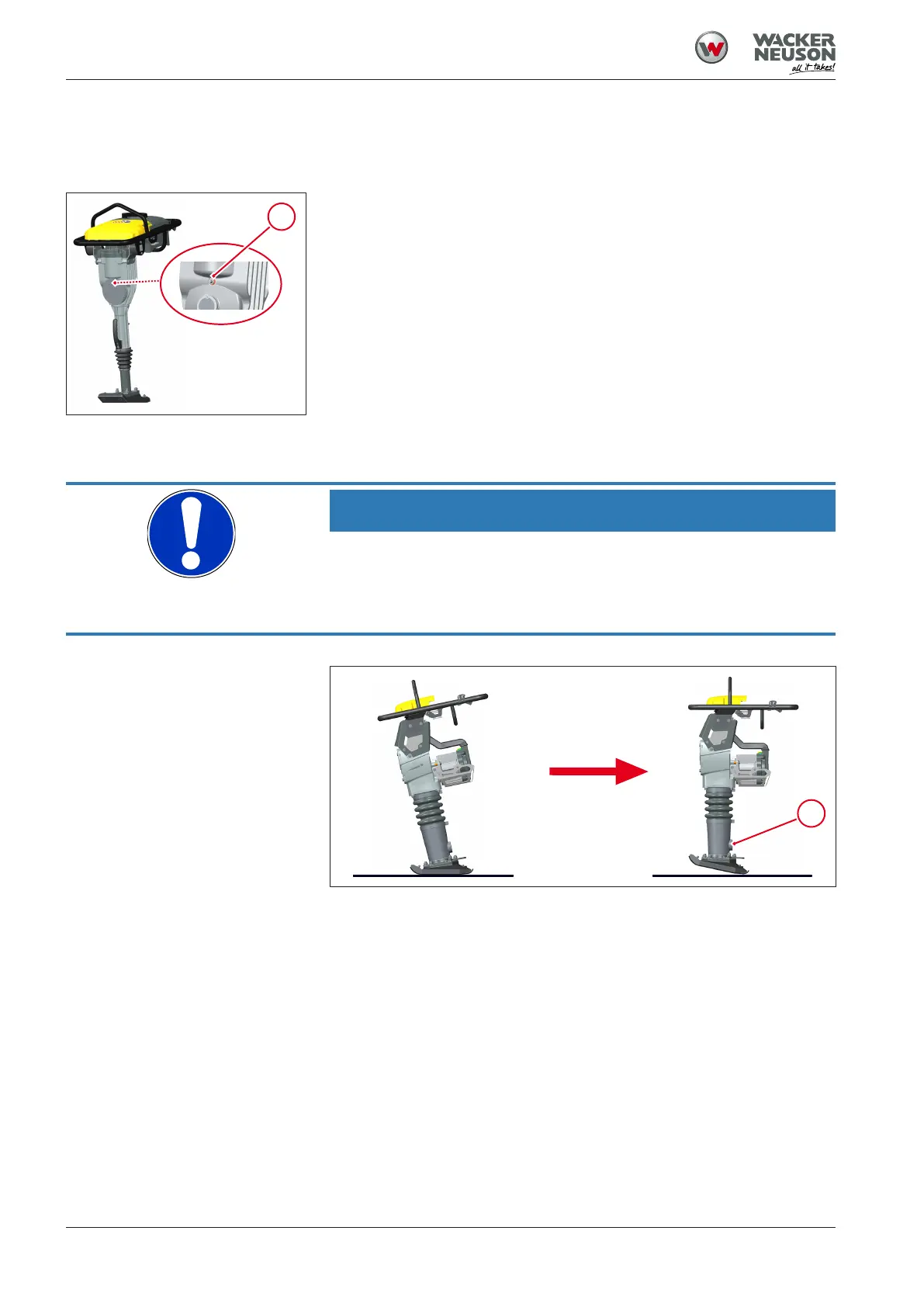

12.3.3 Grease ramming system

AS30e

1 Grease nipples

ü Remove dirt in the area of the grease nipple 1.

1. Place the filled grease gun on the grease nipple and actuate it ap-

prox. 20 times (approx. 30g).

2. Wipe the area of the grease nipple with a clean cloth.

12.3.4 Check oil level and top up

NOTICE

Damage to machine due to incorrect oil level!

A too high oil level can result in a hydraulic lock in the ramming system.

This can lead to faulty operation and damage to the ramming system.

► Do not overfill the ramming system with oil.

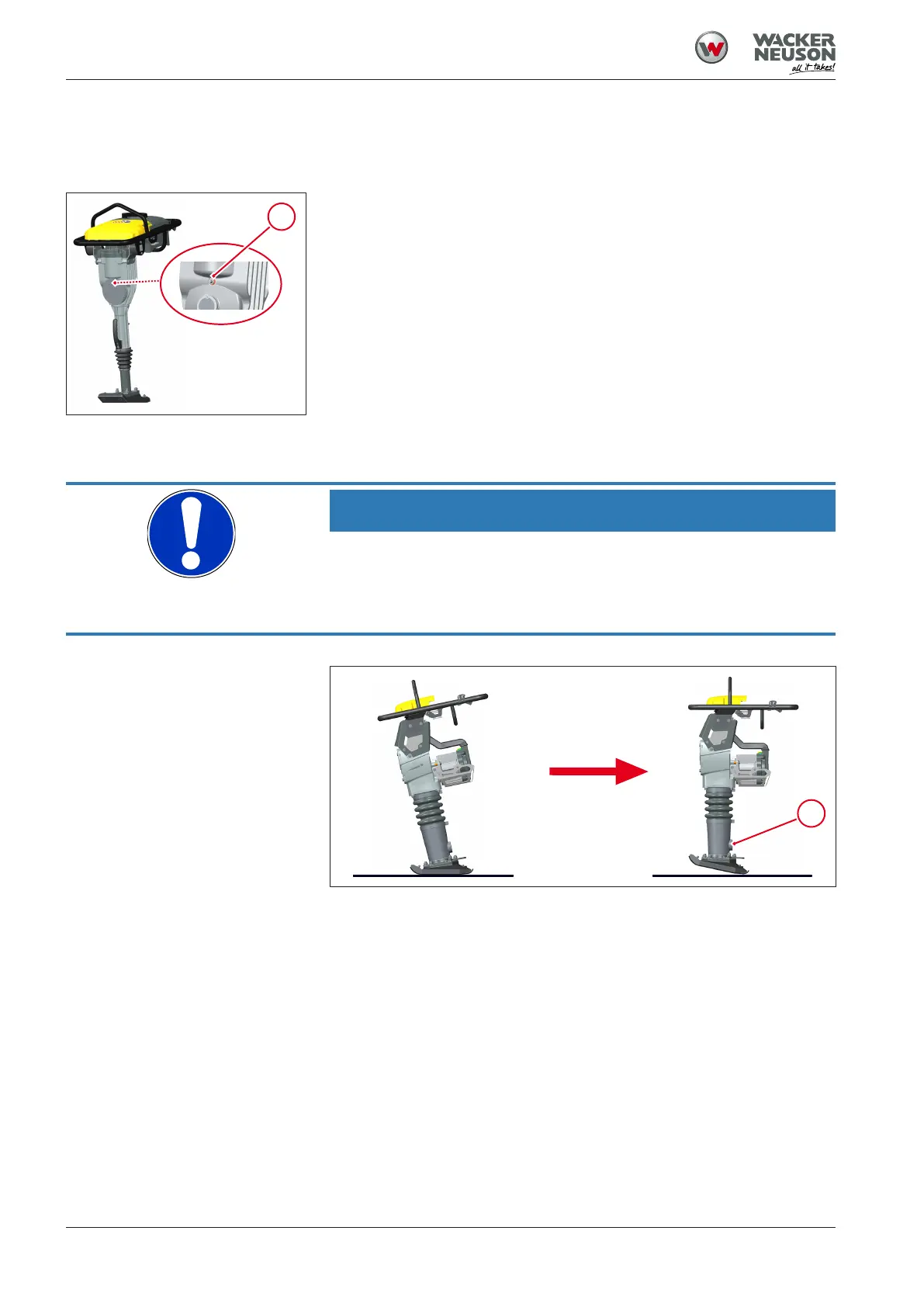

ü After transporting or storing the machine in a horizontal position, it is

necessary to let it be in an upright position for at least 15 minutes be-

fore checking the oil level.

1. Remove dirt in the area of the oil sight glass 1.

2. Tilt the machine so that it forms a right angle b to the floor.

3. Check the oil level by using the oil sight glass.

ð Oil level must be between ½ and ¾.

4. Add oil if the oil level is low. For oil specifications see Technical data

on page 56.

Loading...

Loading...