11 Maintenance

100_0101_mt_0009.fm 29

11.2.2 HMS

11.3 Maintenance work

Working in the workshop

Perform maintenance work in a workshop on a workbench. This has the following advantages:

Protection of the equipment from dirt on the construction site.

A level and clean working surface makes work easier.

Small parts are easier to see and therefore are harder to lose.

Visual inspection for damage

Check all components of the HMS for damage.

Check the drive motor for damage or cracks.

Check to ensure the ON/OFF switch of the drive motor is functioning.

11.3.1 Clean HMS

Clean the HMS after application.

Wipe down the drive motor and flexible shaft with a damp clean cloth.

Clean the ventilation slots with an appropriate, non-metallic auxiliary tool.

Clean the vibrator head and protection hose with water.

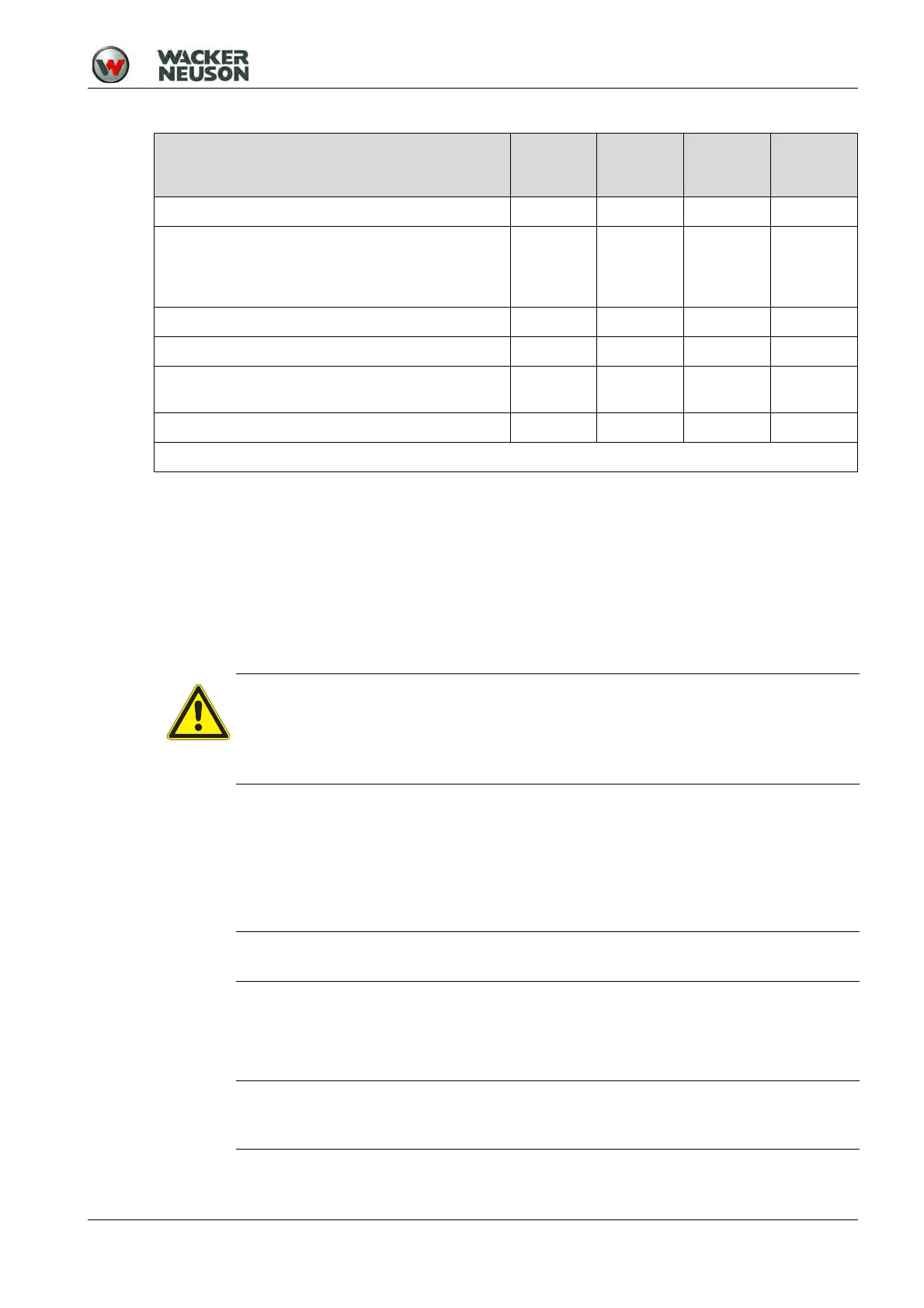

Activity Daily

before

operation

Every 50

hours

Every 100

hours

Every 300

hours

Visual inspection of all elements for damage.

Check to ensure the connection links are firmly seated:

Flexible shaft – vibrator head: tighten if necessary.

Flexible shaft – drive motor: securely lock the

coupling into place if necessary.

Clean HMS.

Check wear dimensions of the vibrator head.

Lubricate the flexible shaft and exchange the plastic

bushing.

Replace the oil in the vibrator head.*

*

Have this work performed by the service department of your Wacker Neuson contact partner.

WARNING

Damage to an equipment part or power cable can lead to physical injury from electric

shock.

Do not operate damaged equipment.

Have damaged equipment repaired immediately.

NOTICE

Do not clean the equipment with high pressure or steam cleaners!

NOTICE

With the equipment running, you can remove the concrete residue from the vibrator head

by immersing it in a gravel bed.

Loading...

Loading...