22

OPERATING MANUAL

VERSION 01/2013 ORDER NUMBER DOC 2333538

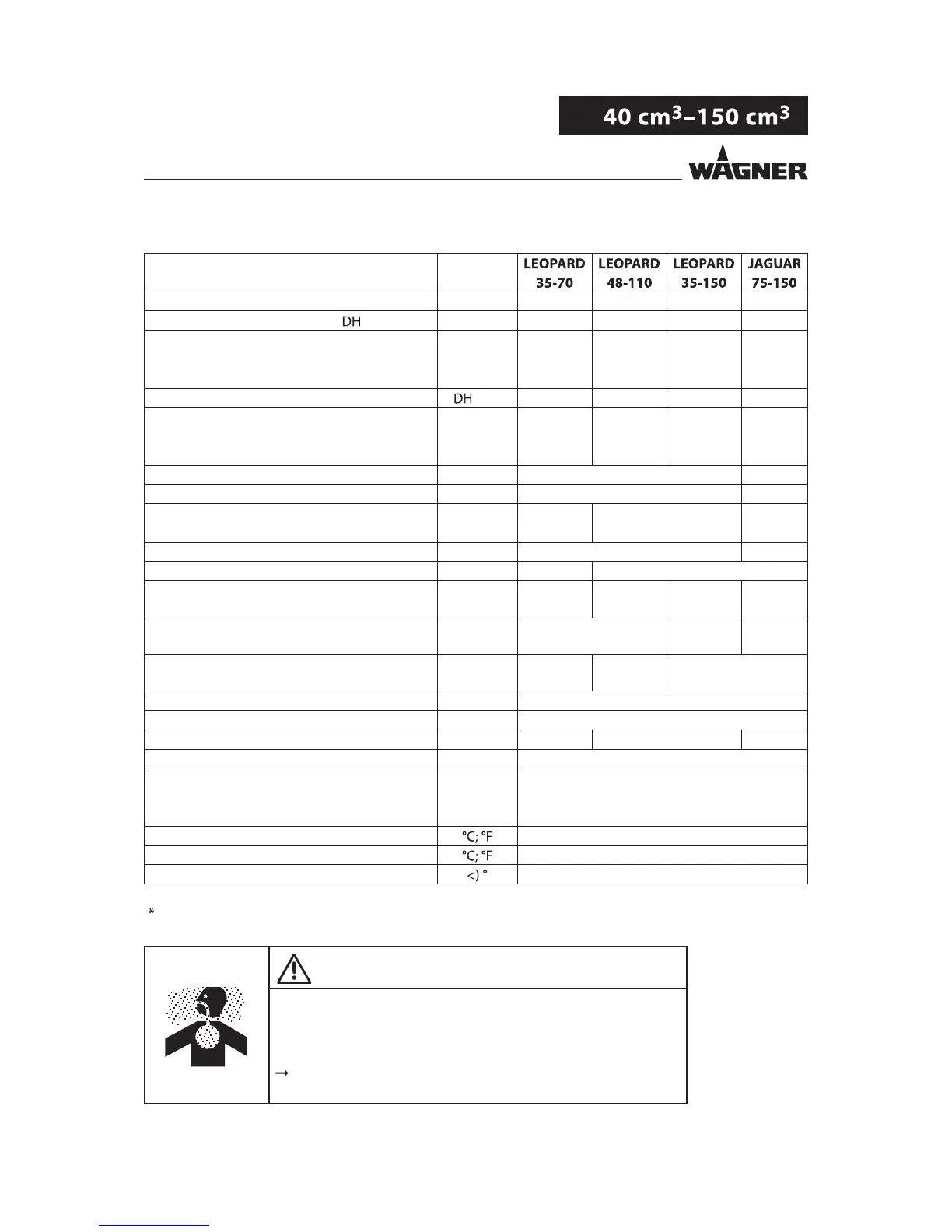

Description Units

Pump ratio 35 : 1 48 :1 35 : 1 75:1

Volume ow per double stroke ( ) cm; cc 70 110 150 150

Maximum operating pressure MPa 25 37 27 53

bar 250 370 270 530

psi 3,626 5,366 3,916 7,687

Maximum possible strokes in operation

/min 60 60 60 60

Minimum / maximum air inlet pressure MPa 0.25-0.71 0.25-0.8 0.25-0.77 0.25-0.71

bar 2.5-7.1 2.5-8 2.5-7.7 2.5-7.1

psi 36-103 36-116 36-112 36-103

Ø air inlet connection (inside thread) inch G1/2" G1"

Minimum Ø of the compressed air supply line mm; inch 13; 0.51 25; 0.98

Air consumption at 0.6 MPa; 6 bar; 87 psi per

double stroke

nl 18.6 37.3 79.9

scf 0.66 1.32 2.82

Diameter piston of air motor mm; inch 150; 6 220; 8.7

Air motor piston stroke mm; inch 75; 3 150; 6

Sound pressure level at maximum permissible

air pressure*

dB(A) 77 78 80 83

Sound pressure level at 0.6 MPa; 6 bar; 87 psi

air pressure*

dB(A) 74 78 81

Sound pressure level at 0.4 MPa; 4 bar; 58 psi

air pressure*

dB(A) 71 69 74

Ø material inlet connection (outside thread) mm M36x2

Material outlet (outside thread) mm M24x1.5

Weight kg; lb 26; 57 36; 79 53; 117

Material pH pH 3.5 ÷ 9

Maximum material pressure at pump inlet MPa 2

bar 20

psi 290

Material temperature

+5 ÷ +80; +41 ÷ +176

Ambient temperature +5 ÷ +60; +41 ÷ +140

Allowable inclination for operation ± 10

A rated sound pressure level measured at 1 m distance, LpA1m according to DIN EN 14462: 2005.

Reference measurements have been made by SUVA (Swiss accident insurance institute).

5.3.3.3 TECHNICAL DATA FOR LEOPARD AND JAGUAR

Outgoing air containing oil!

Risk of poisoning if inhaled.

Air motor switching problems.

Provide compressed air free from oil and water (quality standard

5.5.4 according to ISO 8573.1) 5.5.4 = 40 m / +7 / 5 mg/m³.

WARNING

Loading...

Loading...