32

Installation manual

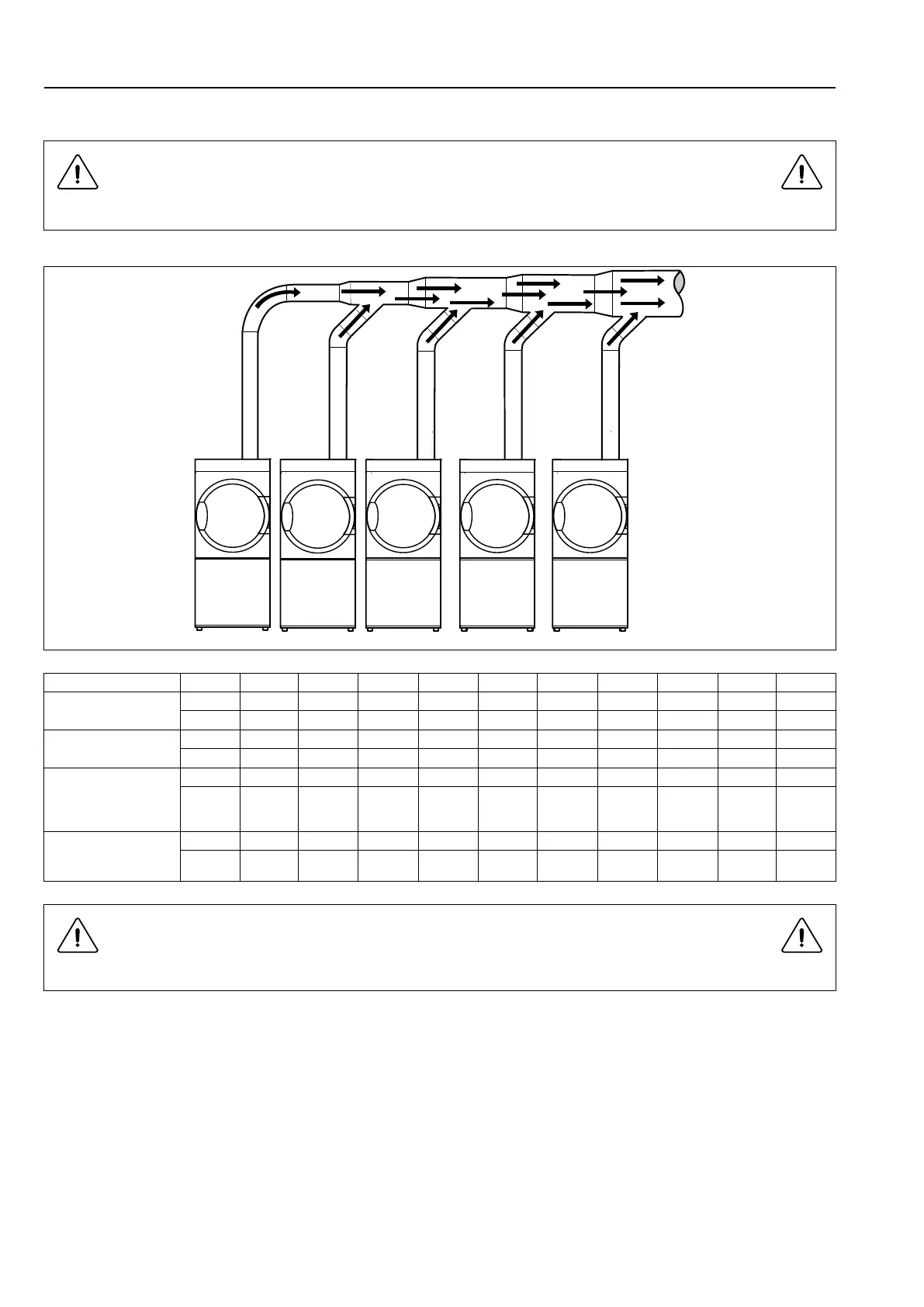

6.4 Shared exhaust duct

It is recommended that each machine is connected to a separate exhaust duct.

When several machines shall use the same exhaust duct the exhaust duct must increase after each machine.

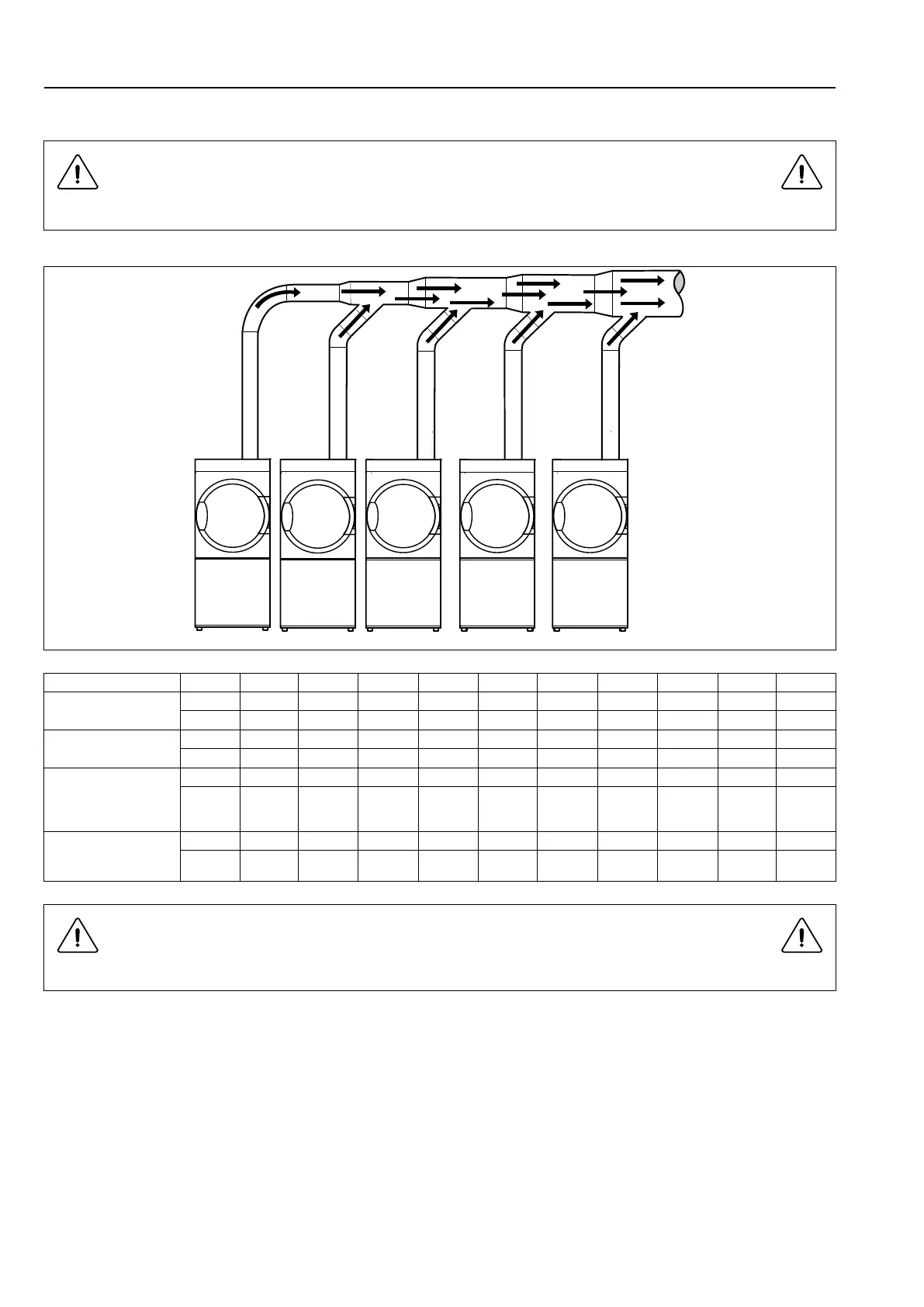

Number of machines 1 2 3 4 5 6 7 8 9 10

Exhaust duct

⌀ mm

200 315 400 400 500 500 630 630 630 800

⌀ inch 8 11 14 16 18 20 22 24 24 26

Recommended area

of fresh air intake

m

2

0.16 0.39 0.63 0.63 0.98 0.98 1.56 1.56 1.56 2.51

ft

2

1.72 3.34 5.38 7 8.83 10.87 13.24 15.72 15.72 18.4

Minimum area of

fresh air intake

Gas heated/Electric

heated

m

2

0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4 0.45 0.5

ft

2

- - - - - - - - - -

Minimum area of

fresh air intake

Steam heated

m

2

0.039 0.078 0.117 0.156 0.195 0.234 0.273 0.312 0.351 0.39

ft

2

0.42 0.84 1.26 1.68 2.1 2.52 2.94 3.36 3.78 4.2

The exhaust duct diameter must not be reduced.

6.5 Exhaust dimensioning

It is important that the machine has correct air volume compared to each machines power.

If the air flow is smaller or larger this will result in a longer drying period.

The machine is designed to work with the maximum static back pressure according to the table in the technical data

section.

The exhaust duct must be designed so the static back pressure measured 1 m / 39 3/8 inch from the exhaust outlet

does not exceed the maximum allowable back pressure specified in Technical data.

If the outlet pipe is longer or the ventilation is not properly designed we recommend to clean the outlet pipes

periodically.

All cover panels must be mounted in order for the machine to work in the best way.

Loading...

Loading...