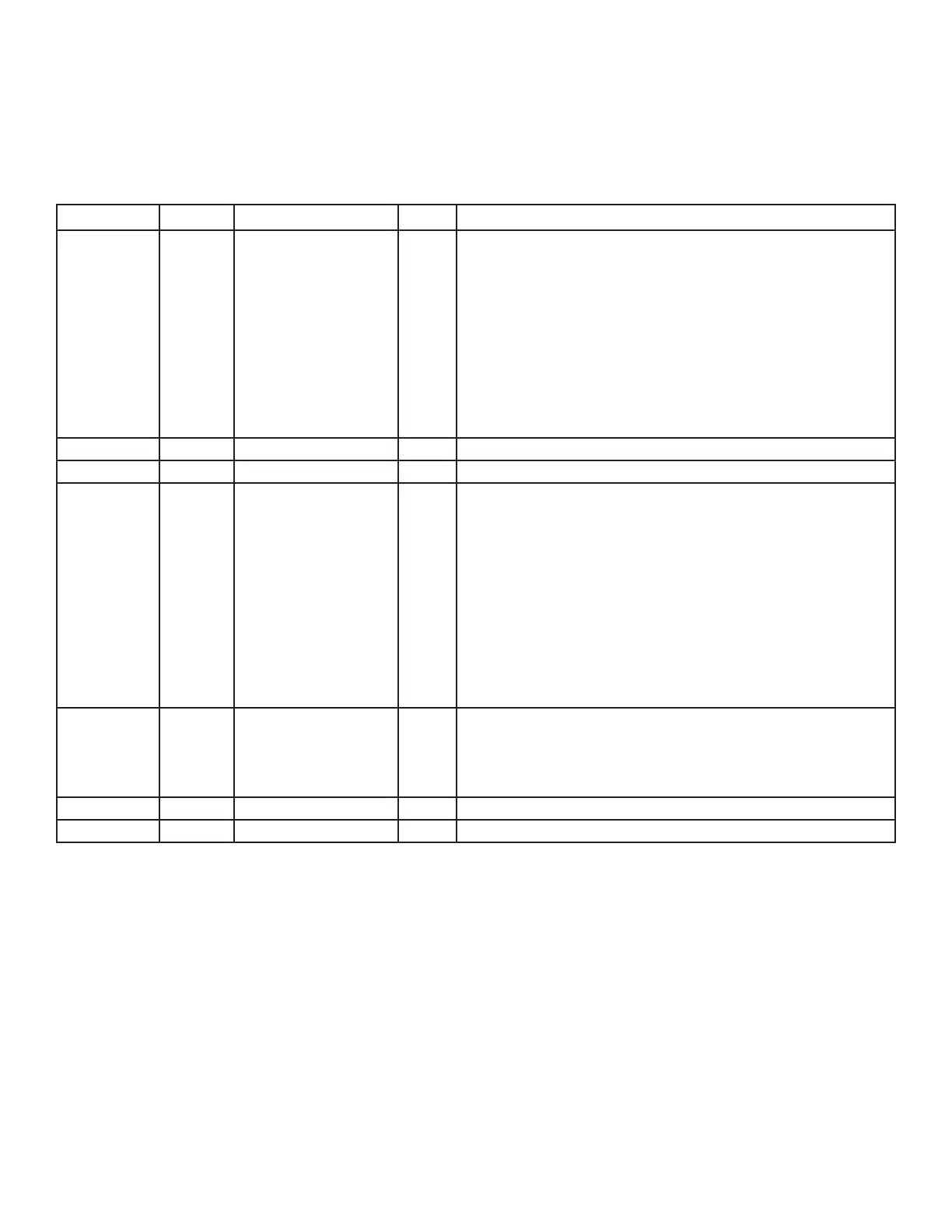

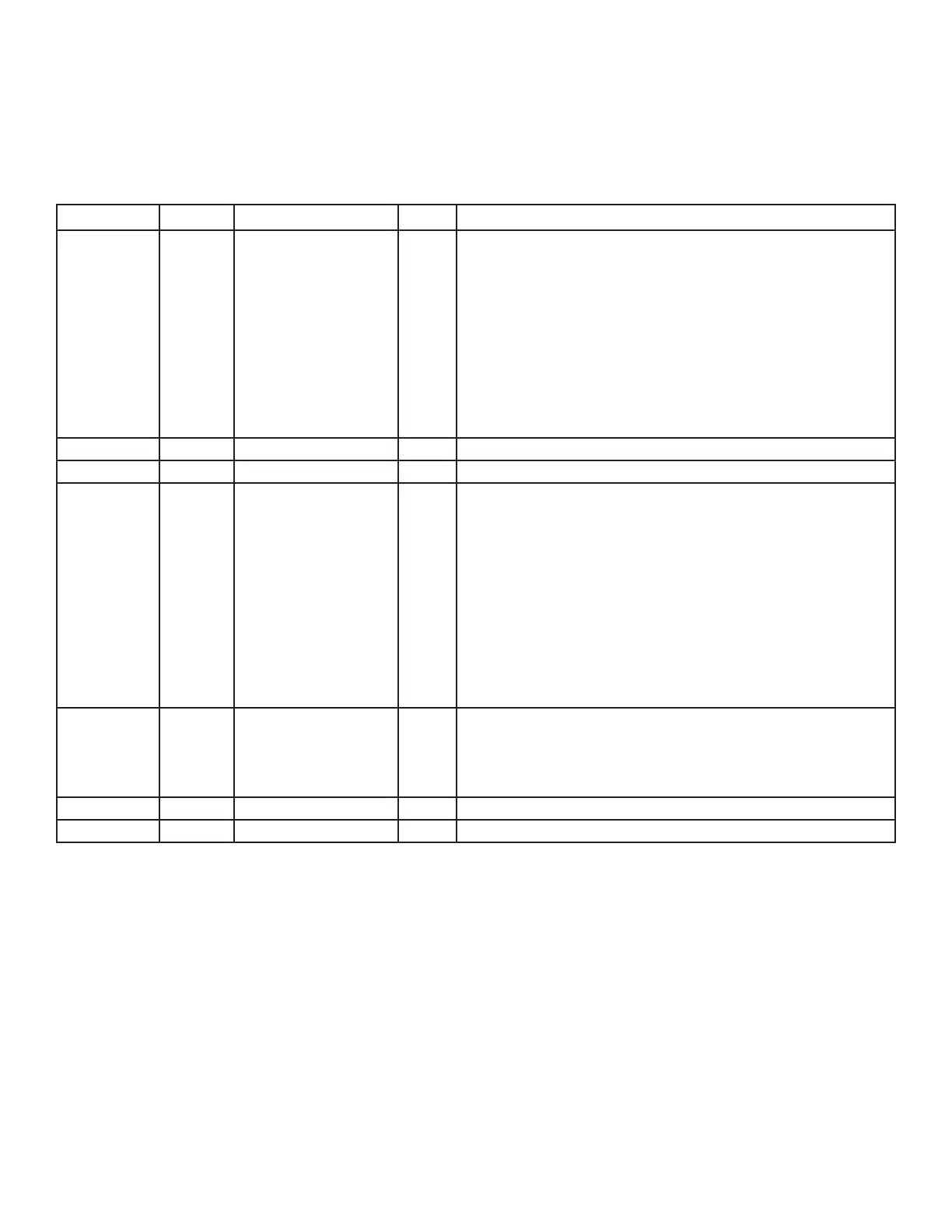

Parts Diagrams

I/O Adapter Assembly

Figure 14

Figure# Part# Item Qty. Description

1 54510 3/4”I/O Assembly 1 Makes the connection between the plumbing and Main Valve Body.

Also, contains the “Hard Water” Blending Valve. The seal areas of

the O-rings at the Main Valve Body inlet and outlet must be smooth

and free of defects and debris, and be lubricated with silicon grease

before assembly. When attaching to the Main Valve Body, put the

O-rings on the male bosses on the Main Valve Body and push the

Adapter into place. A “snap” can be heard when the ADAPTER

slides into place; if not, the O-rings may be “pinched.” If O-rings are

pinched, replace with new ones. The I/O Adapter comes pre-assem-

bled with the sensor housing and turbine axle.

These are not fi eld serviceable and if damaged, must be replaced

with a new assembly.

2 90232 Sensor Cap 1 The Sensor Cap should be snapped in place.

3 90809 Screw, Sensor Cap 1

4 93858 Turbine Sensor

Assembly

1 Picks up the magnetic fi eld from the Turbine and relays it to the

Controller. The three wire assembly connecting the “black-wafer”

Hall-Effect Sensor or the Controller board must not be severely bent

(folded over), cut, or broken. Care should be taken when putting the

Sensor into the Sensor Housing. The “spring” fl ap below the Sensor

must be gently bent over (on top of) the Sensor, and then the Sensor

slide all the way into the Sensor Housing. The round hole of the Sen-

sor mounting tab is then placed down over the mounting screw boss.

The cap is then put in place and the mounting screw is installed. A

slot is provided in the cap for the wire way to exit. The three-wire

socket connector must be properly installed in the controller. Stops

on the connector prevent improper (upside down) assembly. Do not

force the connector past the stops.

5 90522 Turbine Assembly 1 The Turbine must have a 1/8” diameter Rare Earth magnet pressed

into place adjacent to the axle opening. When assembled to the

axle, the Turbine should spin freely. Do not use any lubricants. If the

Turbine should become “jammed,” clean and fl ush

the Turbine and I/O assembly.

6 93229 Flow Director 1

7 93838 O-Ring 2

25

Loading...

Loading...