Reference Illustrations

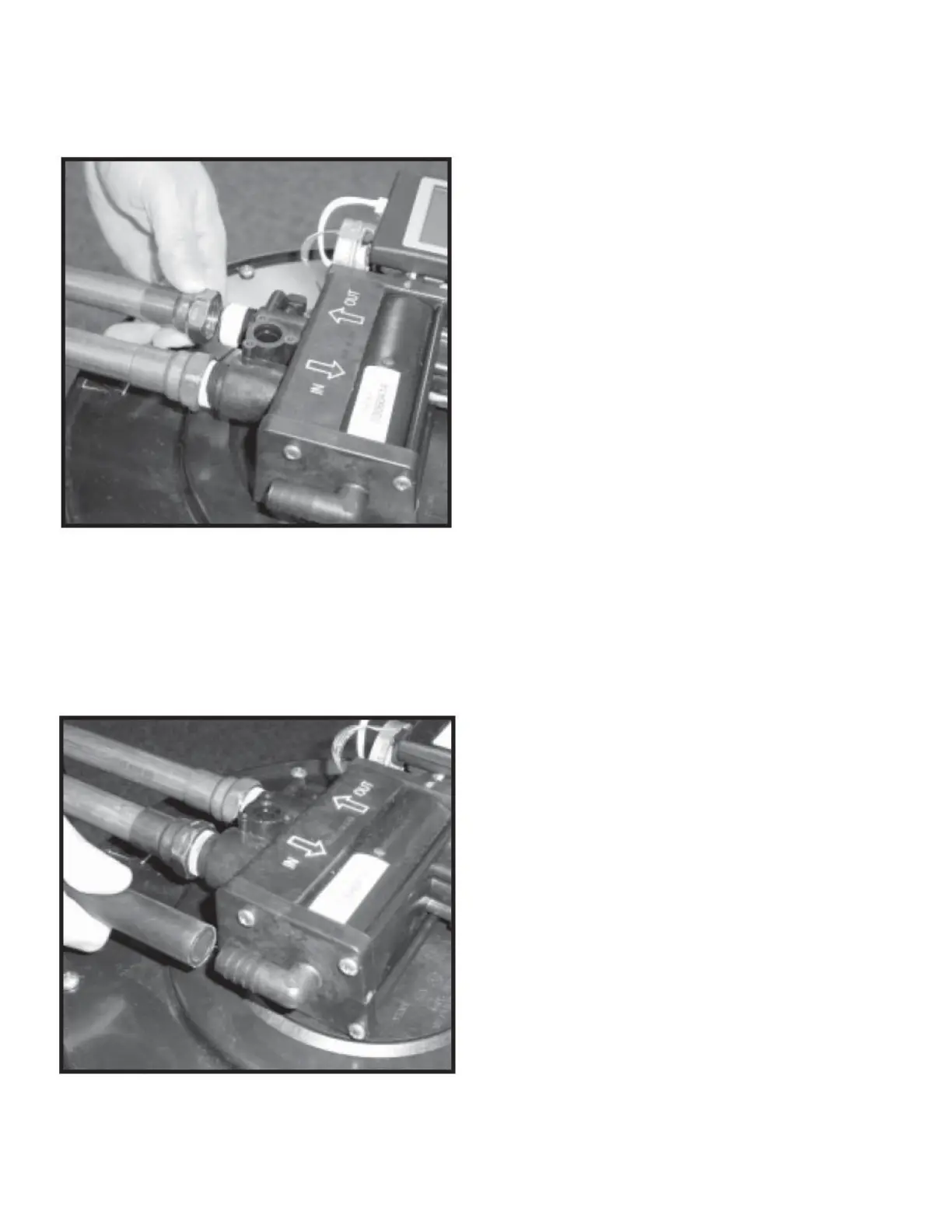

Figure 2

PLUMBING CONNECTIONS

Copper, brass, plastic or other fi ttings may be

used. DO NOT over-tighten fi ttings.

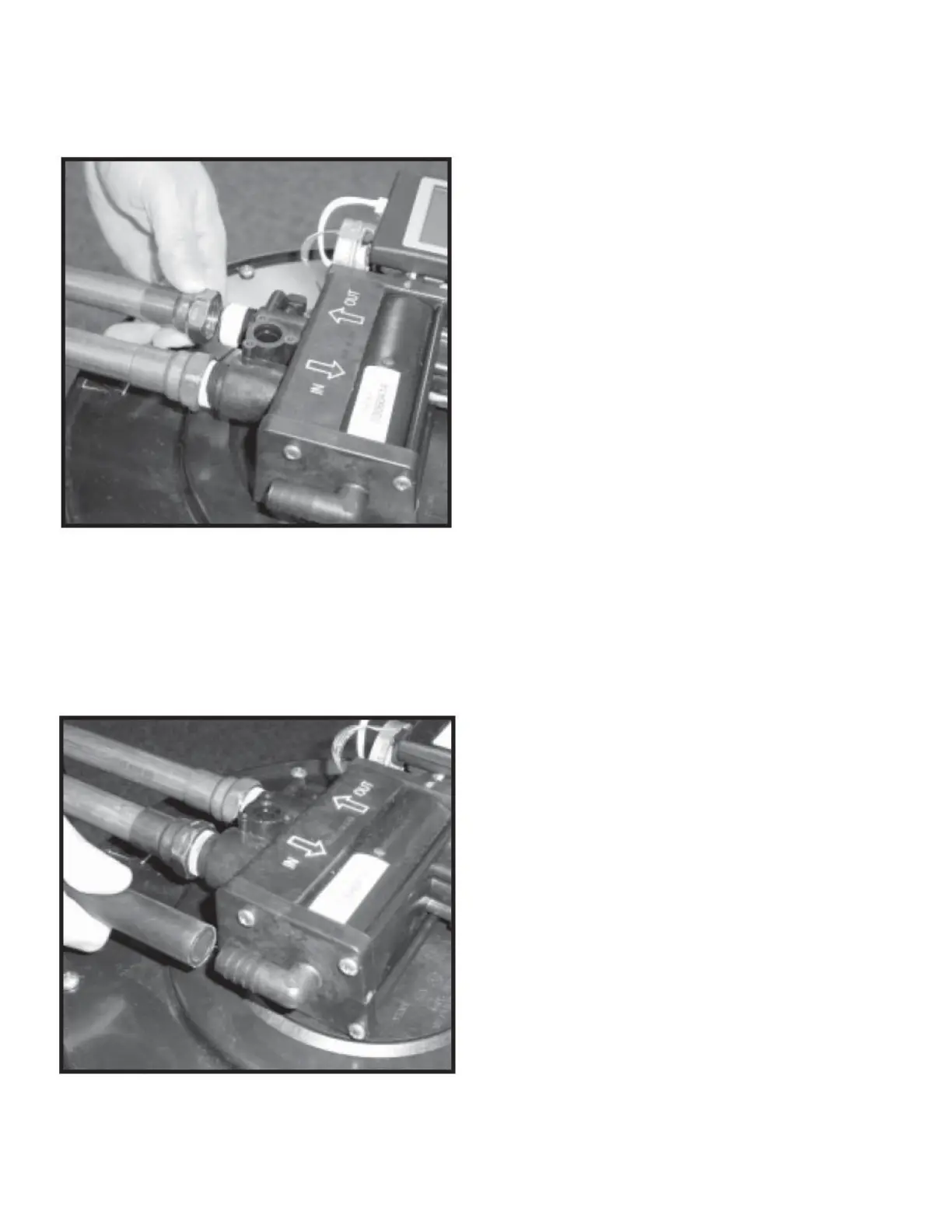

Figure 3

INSTALLATION TIP

When preparing the male threaded fi ttings

of the I/O adapter, follow the guidelines to

avoid damage to the plastic pipe threads.

1. For best results, use 1/2” wide Tefl on®

tape and wrap the threads three times with

each consecutive wrap on top of the

previous wrap. To prevent tearing of the

the tape, use Tefl on® paste on the fi rst two

threads only. This lubricates the tape and

fi lls the small void areas that may exist

between the threads. When the joint is

complete, there will be a small bead of

sealant at the fi tting interface indicating a

properly joined connection.

2. When preparing copper fi ttings, it is al-

ways advisable to use a union where there

is a threaded connection to facilitate

repairing a potential leak in one of your

soldered joints.

3. To prevent heat damage to the plastic

pipe threads of the adapter, prepare the

copper tail assemblies ahead of time so they

can cool down before fi nal assembly. The

copper tube length should be a minimum of

4-1/2” long. To prevent cross threading, turn

the fi tting counterclockwise until you feel the

threads engage, then tighten.

Do not overtighten the fi ttings.

CAUTION NOTE: To avoid damage, do

not allow heat from the torch to be trans-

ferred to the plastic valve component.

9

Loading...

Loading...