Benchmark Platinum-Edge: Operation-Service Manual

SECTION 4 – INITIAL START-UP

OMM-0137_D • GF-211 • 7/16/2019 Technical Support • (800) 526-0288 • Mon-Fri, 8 am - 5 pm EST Page 44 of 146

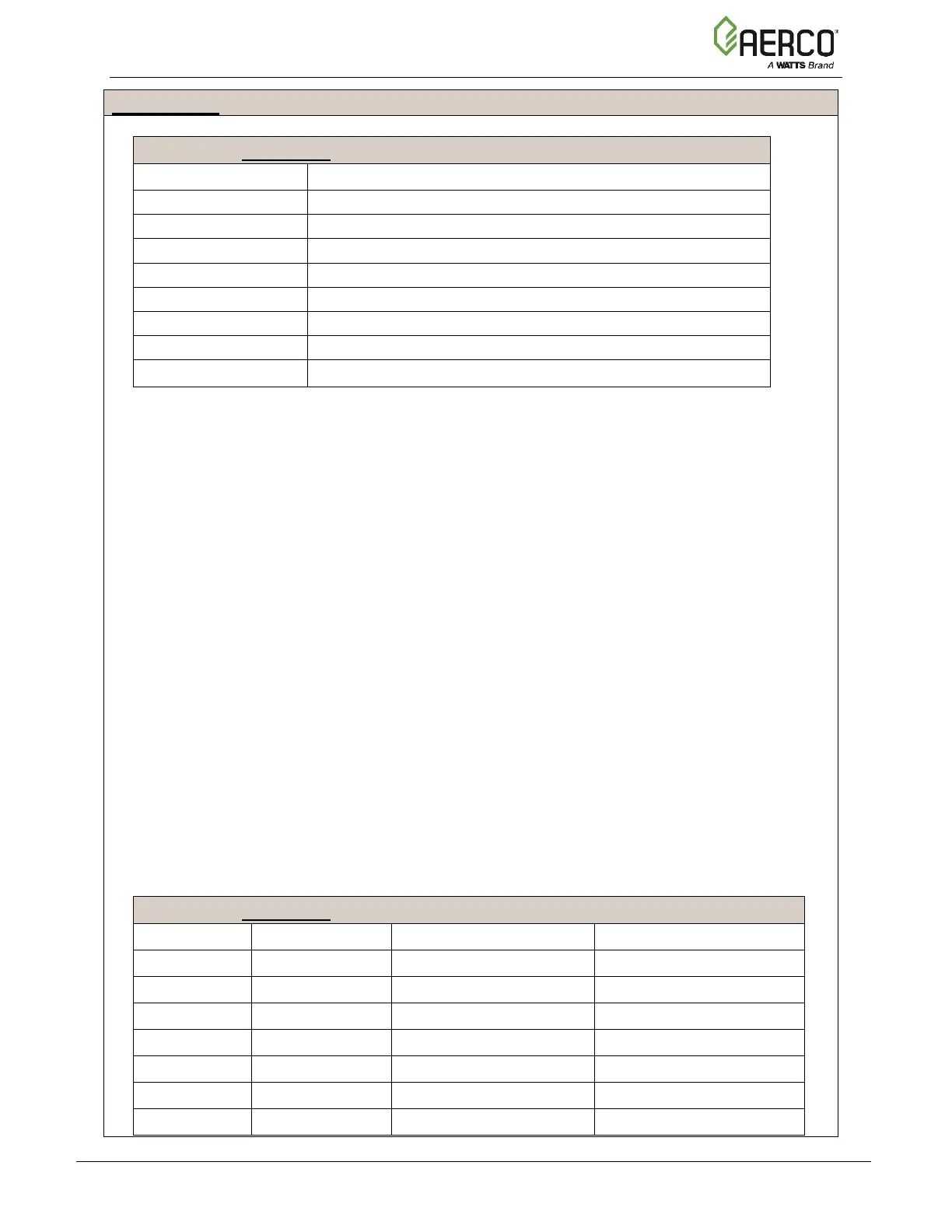

PROPANE Combustion Calibration Instructions

TABLE 4-4: PROPANE Gas Pressure Range @ 100% Fire Rate

Model Nominal Gas Pressure

3.9” W.C. ± 0.2” W.C. (0.97 kPa ± 0.05 kPa)

7.6” W.C. ± 0.2” W.C. (1.89 kPa ± 0.05 kPa)

1.4” W.C. ± 0.1” W.C. (0.35 kPa ± 0.02 kPa)

2.5” W.C. ± 0.1” W.C. (0.62 kPa ± 0.02 kPa)

2500DF & 2500P 2.0” W.C. ± 0.1” W.C. (0.50 kPa ± 0.02 kPa)

1.6” W.C. ± 0.1” W.C. (0.40 kPa ± 0.02 kPa)

2.0” ± 0.2” W.C. (0.50 to 0.05 kPa)

6000DF & 6000P 4.2” ± 0.2” W.C. (1.05 to 0.05 kPa)

16. With the valve position still at 100%, insert the combustion analyzer probe into the exhaust

manifold probe opening (see Figure 4-2a – 4-2c in Section 4.2.3) and allow enough time

for the combustion analyzer reading to stabilize

17. Compare the combustion analyzer’s oxygen (O

2

) reading to the O

2

value in the Reading

column (Figure 4-9). If they differ, go to the Main Menu Calibration Input/Output

Oxygen Sensor screen and adjust the O2 Offset parameter, up to ±3%, to make the on-

board O

2

sensor match the value from the combustion analyzer. If your combustion

analyzer is correctly calibrated, and the on-board O

2

sensor cannot be made to match the

analyzer, the sensor may be defective and need to be replaced.

18. Compare the O

2

value in the Target and Reading columns. If they don’t match, adjust the

Blower Voltage until the O

2

value in both columns match; use either the + or – controls,

or press on the field and type the value directly.

19. If adjusting the blower voltage is not sufficient to get the O

2

Reading column to match the

Target column, then repeat Step 15 to adjust the gas pressure up or down within the range

shown in the table, then repeat Step 18. Continue repeating Steps 15 and 18 until the gas

pressure is within the range in Table 4-4 and the O

2

Reading column to matches the

Target column.

20. Enter the downstream manometer’s gas pressure reading in the Downstream Gas

Pressure field. Note, this field appears only when Valve Position % = 100%.

21. Compare the measured nitrogen oxide (NOx) and carbon monoxide (CO) readings to the

Target values (shown in the Table 4-5 as a reference only). If you are not in a “NOx-

limited” area and/or do not have a NOx measurement in your analyzer, set the O

2

to the

value in the Oxygen (O

2

) % column in the table below.

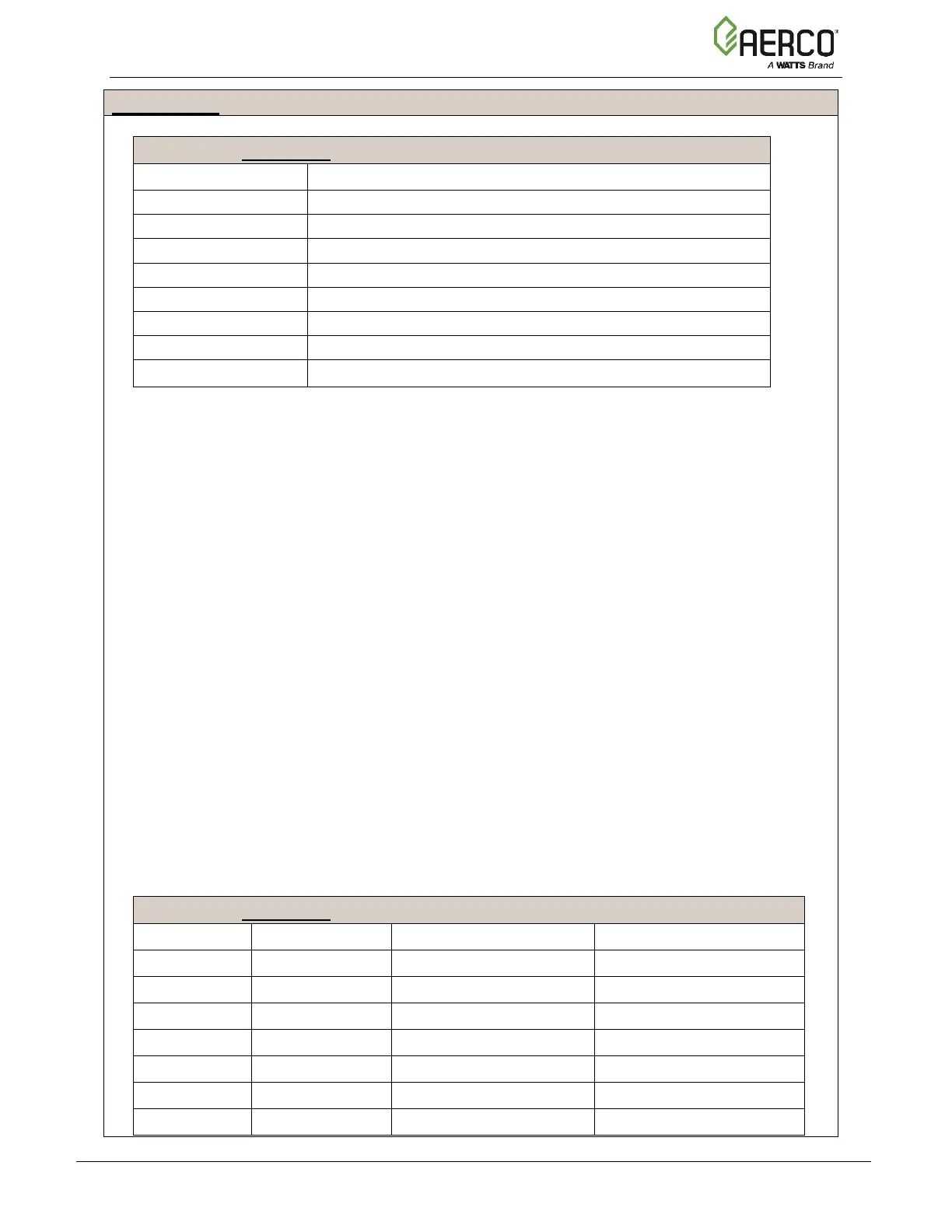

TABLE 4-5: PROPANE Calibration Readings at 100% Valve Position

2

1500 5.2% ± 0.2%

<150 ppm

Loading...

Loading...