STARTING PROCEDURE

STARTING BURNER

1. Be sure main switch is in “OFF” position, thermostat is

substantially above room temperature, the oil tank is

filled, all valves are open, and controls set for

operation.

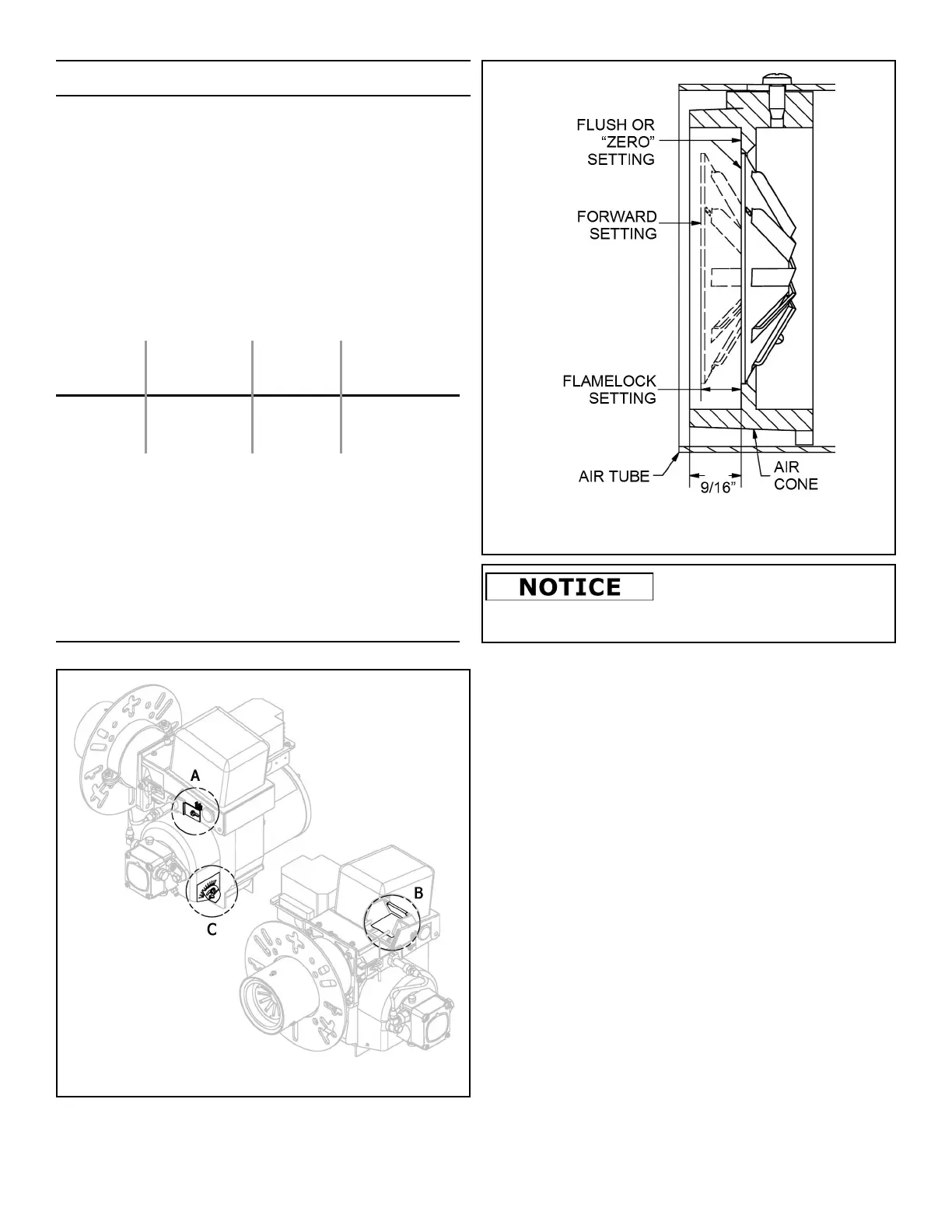

2. Adjust air supply on burner by loosening the screw on

the primary air damper, and open partially. (See

Figure 12 and Table 2 for inputs and damper

adjustments).

Table 2: Listed Burner Settings

GPH INPUT

FLAMELOCK

SETTING

“A”

STATIC

BAFFLE

ANGLE “B”

PRIMARY AIR

DAMPER

“C”

0.50 – 0.75 0 – (*0”) 65°

Set to optimal

CO

2

and trace

smoke.

0.85 – 1.75 2 – (*1/8”) 30°

2.00 – 3.00 8 – (*1/2”) 30°

Burner is equipped with Air Cone to fire 0.50 to 2.50 GPH,

and baffle to fire 0.50 to 0.75 GPH. Use air cone 100531-

001 for inputs over 2.50 GPH, and 30° baffle (packed

w/manual) for inputs over 0.75 GPH.

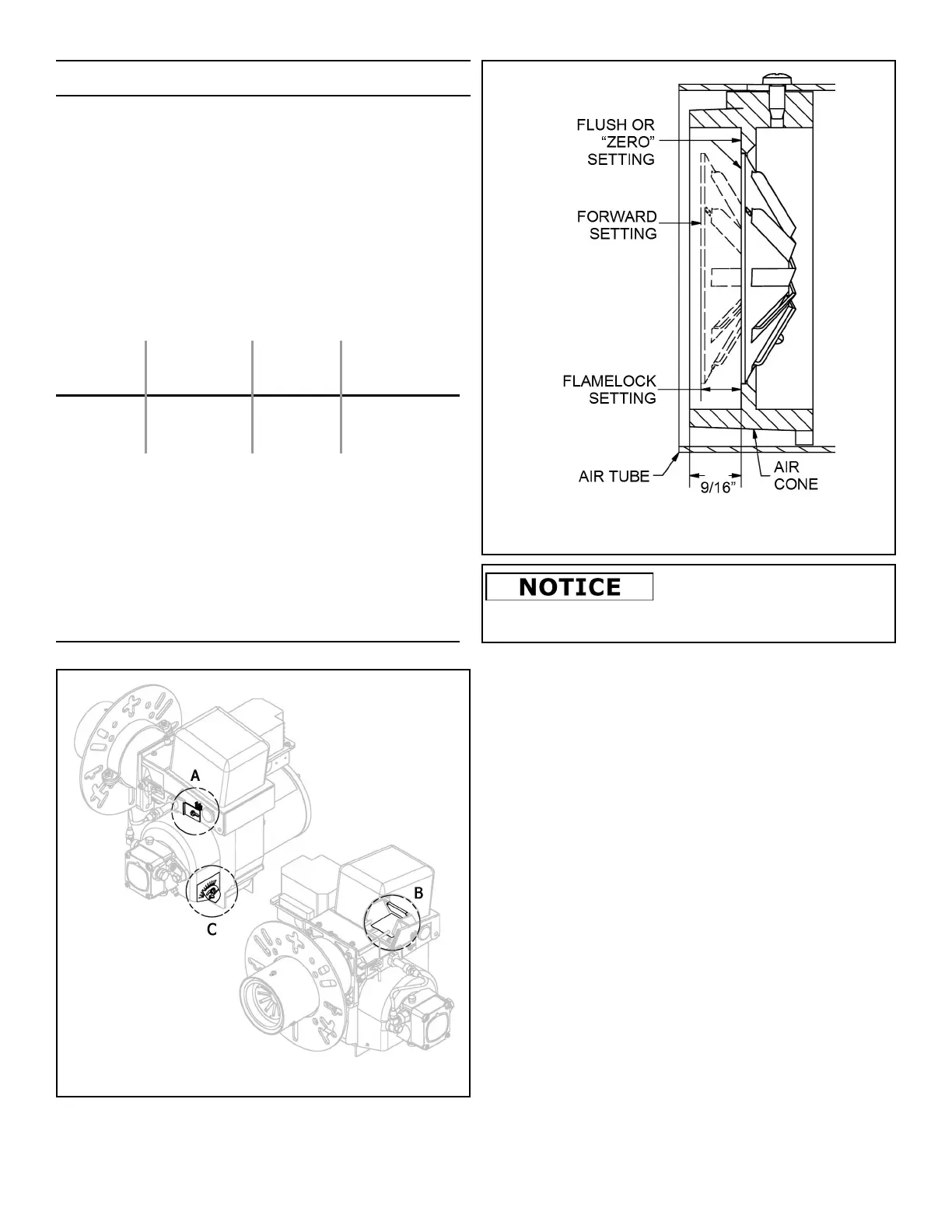

Setting “A” - Flamelock™ settings are a direct reading in

1/16” steps. A number 2 setting indicates the Flamelock™

is 1/8 inch ahead of the Air Cone “Flush Setting”. (See

Figure 13)

Figure 12: Burner Settings

Figure 13: Flamelock Diagram

Note the direction of the air

cone when installing it in the

air tube. The beveled side of the inner diameter is

installed toward the burner.

3. Open the inspection door and turn on switch.

4. Prime pump according to the pump manufacturer’s

recommendations and check pressure. If safety

lockout occurs, reset after one or two minutes. Do not

run fuel pump dry for more than five minutes.

5. When fire is established make a temporary air

adjustment for a clean combustion flame, reduce air

supply until flame tips appear slightly smoky, then

readjust so flame tips are clean looking.

6. Leave inspection door open until chamber is dry.

7. When normal temperatures are reached, close

inspection door. (See page 3 under “Draft

Regulators”).

FINAL ADJUSTMENTS

1. At this point, a final adjustment should be made by the

use of a COMBUSTION TEST KIT.

2. After operating ten minutes to warm up the unit, a

smoke tester should be used to take a smoke reading.

Smoke test should read no greater than #1 (Shell

Bacarach scale), and less than a #1 smoke is desired.

At times, a new heating unit requires more time than

this to burn clean due to the oil film on the new heater

unit surfaces.

7

Loading...

Loading...