Fuel Installation

Fuel Supply

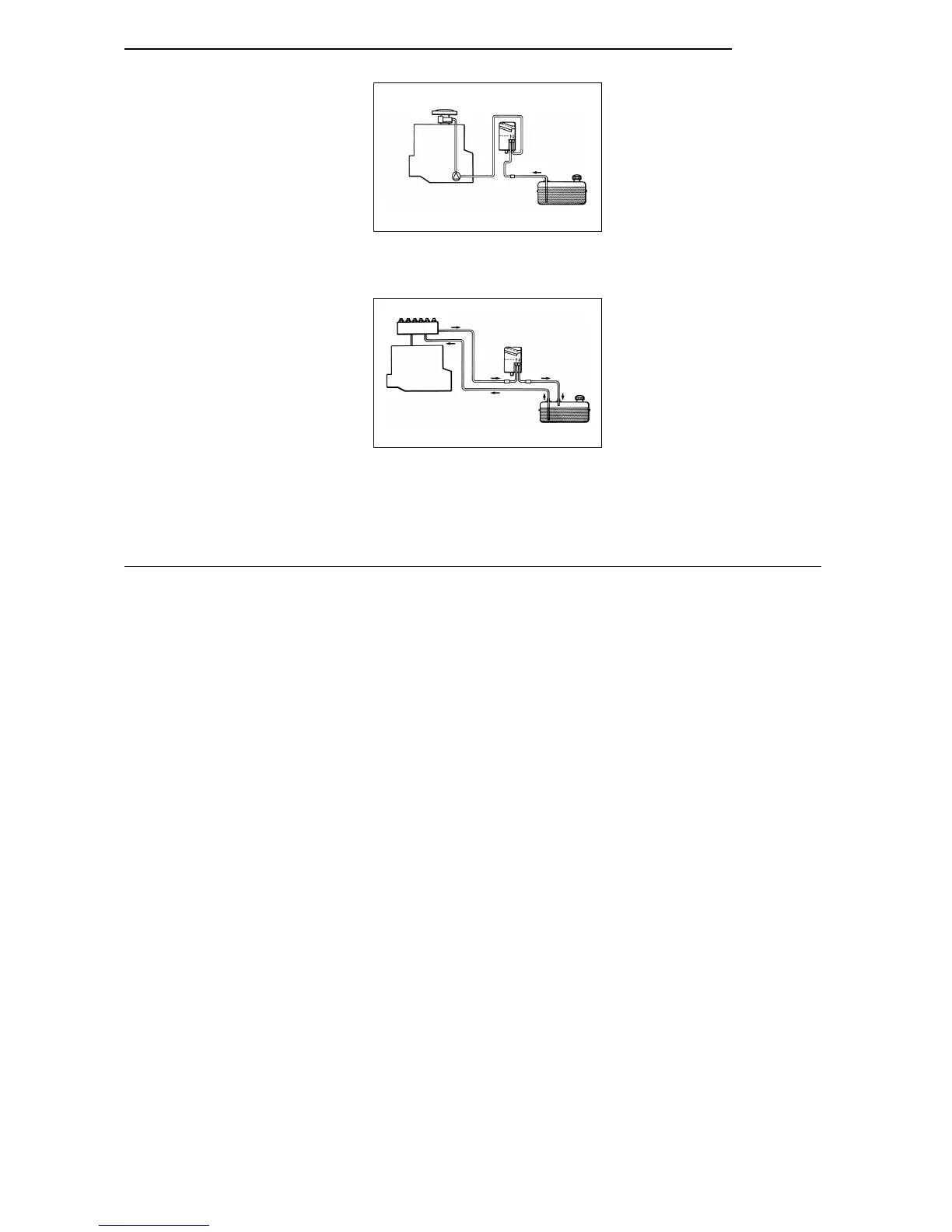

In the case of carburetor or injection engines equipped

with return line, the heater’s fuel supply circuit must be inte-

grated in the return line as shown in Fig. 8.

The direction arrows provided on the heater must be ob-

served.

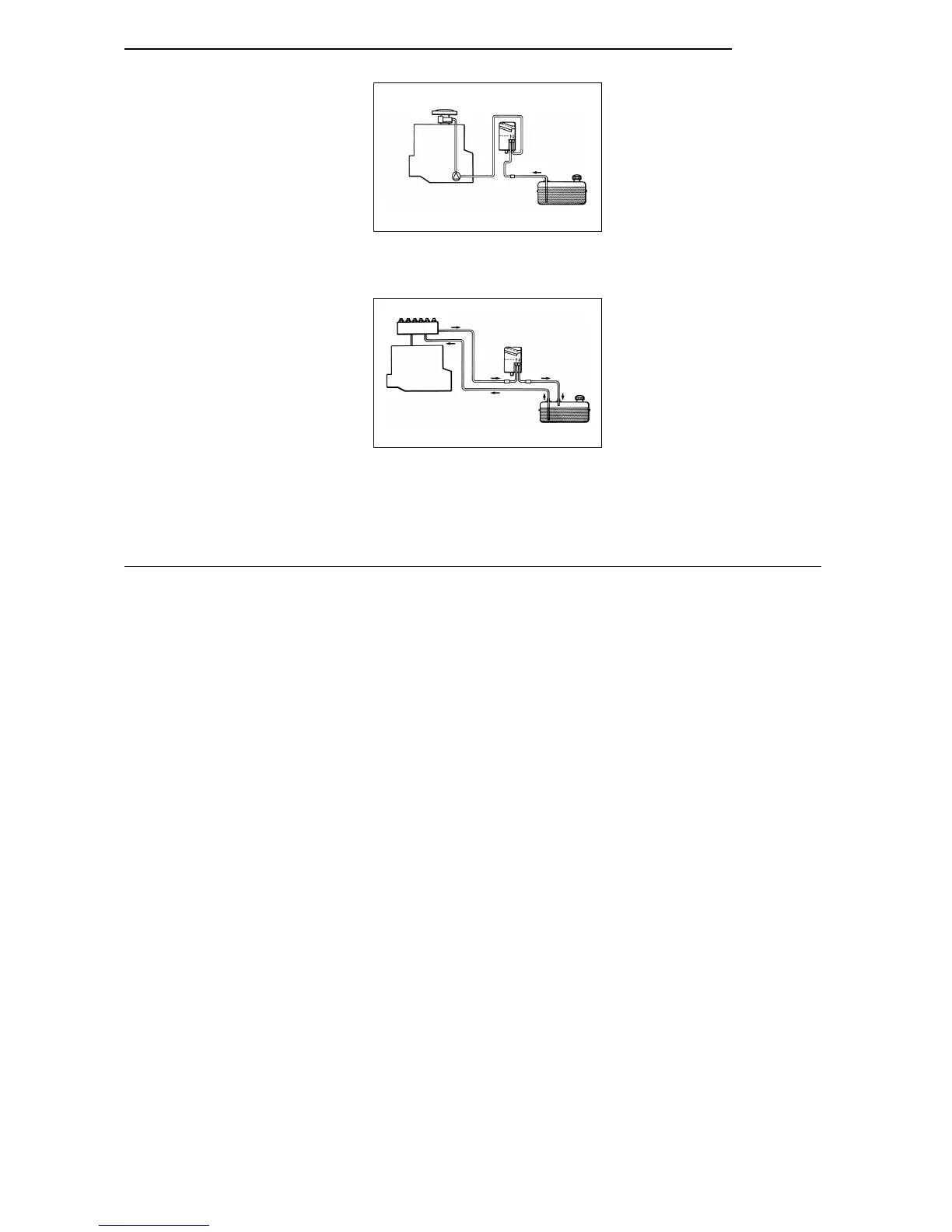

In the case of carburettor engines without return line, the

fuel supply circuit of the heater must be integrated in the

flow line between vehicle fuel tank and pump as shown in

Fig. 7.

ANNOTATION

A fuel flow line can usually be identified by the in-line fuel

filter.

NOTE:

If the fuel system of the vehicle is equipped with a degass-

ing device, fuel extraction is to take place upstream of

same.

Fuel Lines

Only the special hoses supplied with the heater by We-

basto must be used as fuel lines between fuel connections

and heater. When using hoses, the joints are to be se-

cured using hose clamps. To prevent any sagging the fuel

line must be secured with clips.

Prior to cutting the fuel line open it must be clamped off or

a suitable vessel placed underneath the pipe.

Any fuel that may have leaked is to be removed from the

engine or heater prior to starting up the vehicle or heater

The fuel lines - not cut to length as yet - are to be con-

nected to the vehicle’s return line.

Keeping slack to a minimum, they are then to be routed

along any obstructing vehicle parts up to the fuel connec-

tions of the heater and the length thus obtained is to be

marked.

The fuel lines are to be cut off 35 cm longer than marked.

The excess length of the fuel lines of 35 cm is to be dis-

tributed evenly. The fuel lines are to be so fastened that

they will not be damaged by vehicle parts that may come

in contact with them.

The lines must be mounted in such a way that they are pro-

tected from mechanical damage (e.g. stones) and thermal

influence (e.g. exhaust pipe). If the fuel line is damaged

there is a danger of fire.

NOTE:

The hose clamps are to be tightened to a torque of 1.0 +

0.4 Nm.

Combustion Air Supply

Combustion air is to be drawn in from a location as cool as

possible and splash-proof via a combustion air line.

The combustion air line which is contained in the installa-

tion kit must not be extended.

It may be shortened to a min. of 500 mm.

The combustion air line may feature several bends (total of

270°, smallest bending radius 50 mm).

NOTE:

The combustion air line consists of an inside and outside

part.

Shorten combustion air line only at the end that is not pro-

vided with a fastening clip.

fuel pump

engine

carburator

Fig. 7: Fuel Supply Circuit in the Single Line Sys-

tem (Carburetor Engine without Return Line)

“Inline Integration between Pump and Car-

buretor”

engine

injection system

flow pipe

return pipe

Fig. 8: Fuel Supply Circuit in the Double Line Sys-

tem (Carburetor or Injection Motor with Re-

turn Pipe) “Inline Integration in Return Flow”

Thermo Top

21

Loading...

Loading...