Page 13 Burner Mounting CriteriaSC Manual

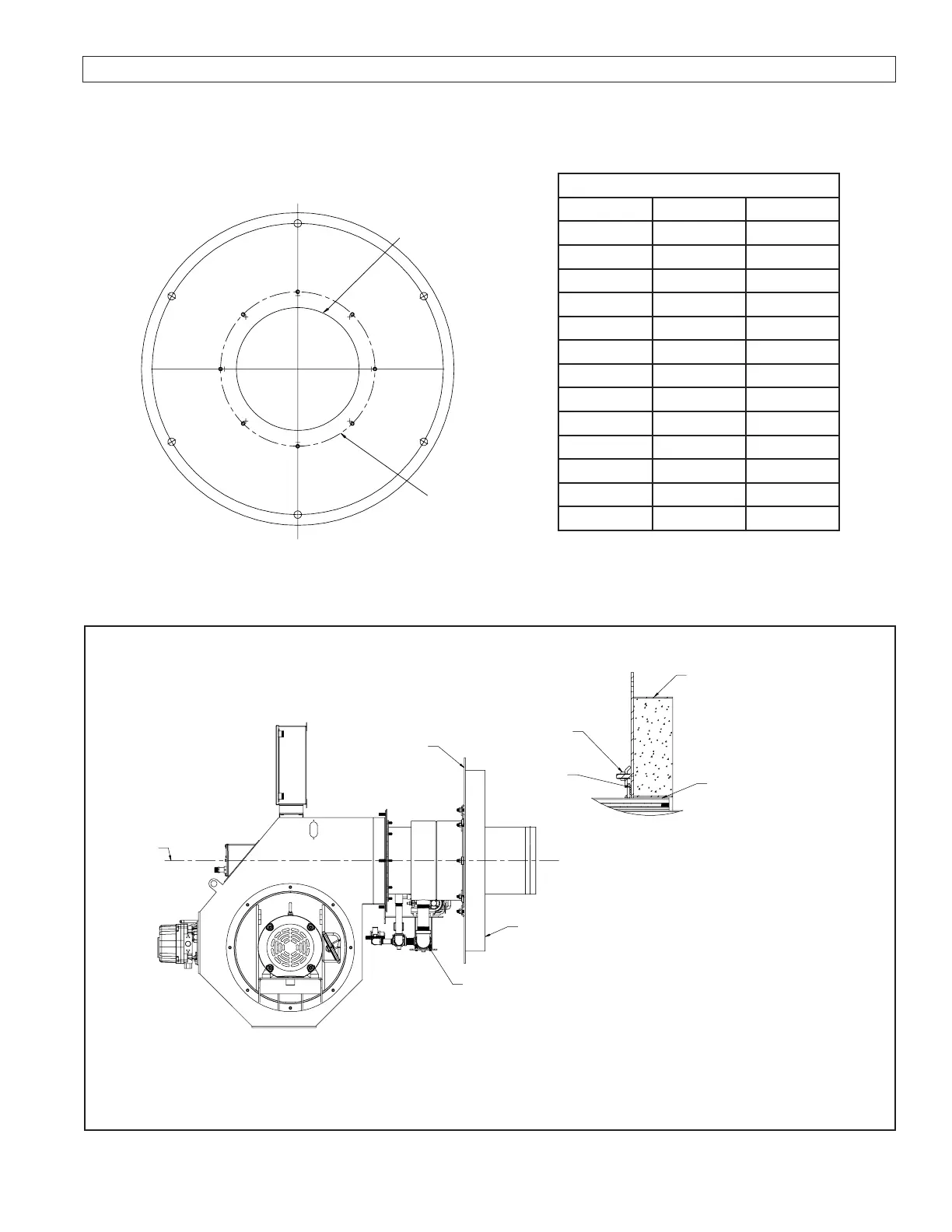

E. BURNER MOUNTING CRITERIA

It is of vital importance that the burner be properly mounted to the boiler or appliance being red. Improper mounting

can cause leakage of the hot gases back around the burner head resulting in warpage and deterioration. The follow-

ing illustrations show the proper way the burner must be installed to validate warranty conditions.

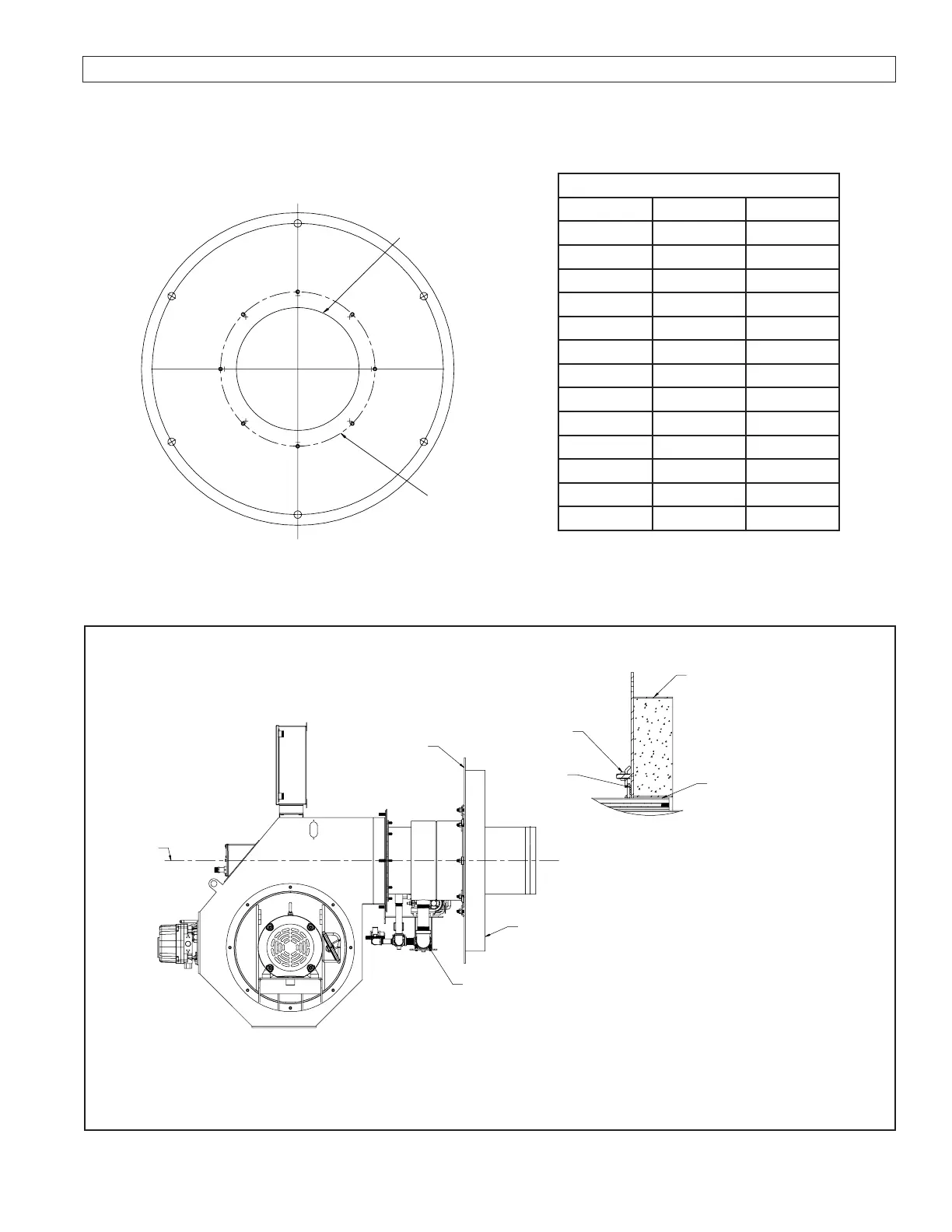

A

B

TYPICAL SC BURNER REFRACTORY FRONTPLATE

Dimensions - Inches

MODEL DIM. A DIM. B

SC8 9.25” 14.00”

SC10 11.25” 16.00”

SC12 13.25” 17.00”

SC12.3 13.56” 19.00”

SC13 15.00” 19.00”

SC13.8 15.00” 19.00”

SC14 15.25” 19.00”

SC15 17.00” 20.50”

SC15.8 17.00” 20.50”

SC16 17.25” 20.50”

SC18 19.25” 22.50”

SC20 21.25” 24.50”

SC24 25.25” 28.50”

Figure E-1

Refractory Dimension

Contact Webster for more detailed

refractory drawings.

Figure E-2

Burner Mounting Instruction

BURNER MUST

BE LEVEL

REFRACTORY

FRONT PLATE

IF GAP IS OVER 3/16”

WRAP BURNER NOSE WITH

HIGH TEMPERATURE

CERAMIC INSULATION ROPE

FILL VOIDS BETWEEN FRONT

PLATE AND VESSEL WITH

CERAMIC BLANKET 4” DEEP

OR AS DEFINED BY VESSEL

MANUFACTURER

THIS SURFACE MUST

BE SEALED AGAINST

THE VESSEL. CHECK

VESSEL MOUNTING

REQUIREMENTS.

THIS SURFACE

MUST BE SEALED

AGAINST THE

VESSEL. CHECK VESSEL

MOUNTING

REQUIREMENTS.

ATTACHMENT TO VESSEL VARIES WITH MANUFACTURE.

(FOLLOW VESSEL MANUFACTURER’S RECOMMENDATION)

THE GAS PIPING FROM THE BURNER TO THE

TRAIN SHOULD HAVE AS FEW ELBOWS AS

POSSIBLE TO REDUCE PRESSURE DROP.

Loading...

Loading...