i. Check safety limits, including pressure and

temperature switches.

6. Combustion Air Fan

If the fan and motor are ever removed, the following

should be observed in re-assembly.

a. There should be 1/16” overlap of inlet cone and fan.

b. Never re-use the fan to motor shaft set screws,

always use new screws of the same type and style

to maintain balance and fan retention.

c. When tightening the fan hub set screws, rotate the

fan to place the screws on the bottom. This way the

screw is not lifting the fan.

d. The motor shaft and fan hub must be clean and free

of burrs.

7. Ignitor Replacement

To remove the ignitor on the SC series from the

combustion head start by removing the housing cover

plate. Then use a 7/16” crowfoot wrench on a 24” (or

longer) extension to remove the ignition shoe from the

ignitor. Change the crowfoot out for a 9/16” socket and

unscrew the ignitor. Use a 3/8” baby crowfoot wrench to

guide the spark plug from the ignitor collar.

In order to put the spark plug back in place, place the

ignitor in the 7/16” socket and then put the ignitor in place

by pushing it all the way in. Secure the position of the

spark plug by tightening the compression tting with the

7/16” socket. Use the crowfoot wrench to put the ignition

shoe back onto the spark plug.

Page 29 General Maintenance And CareSC Manual

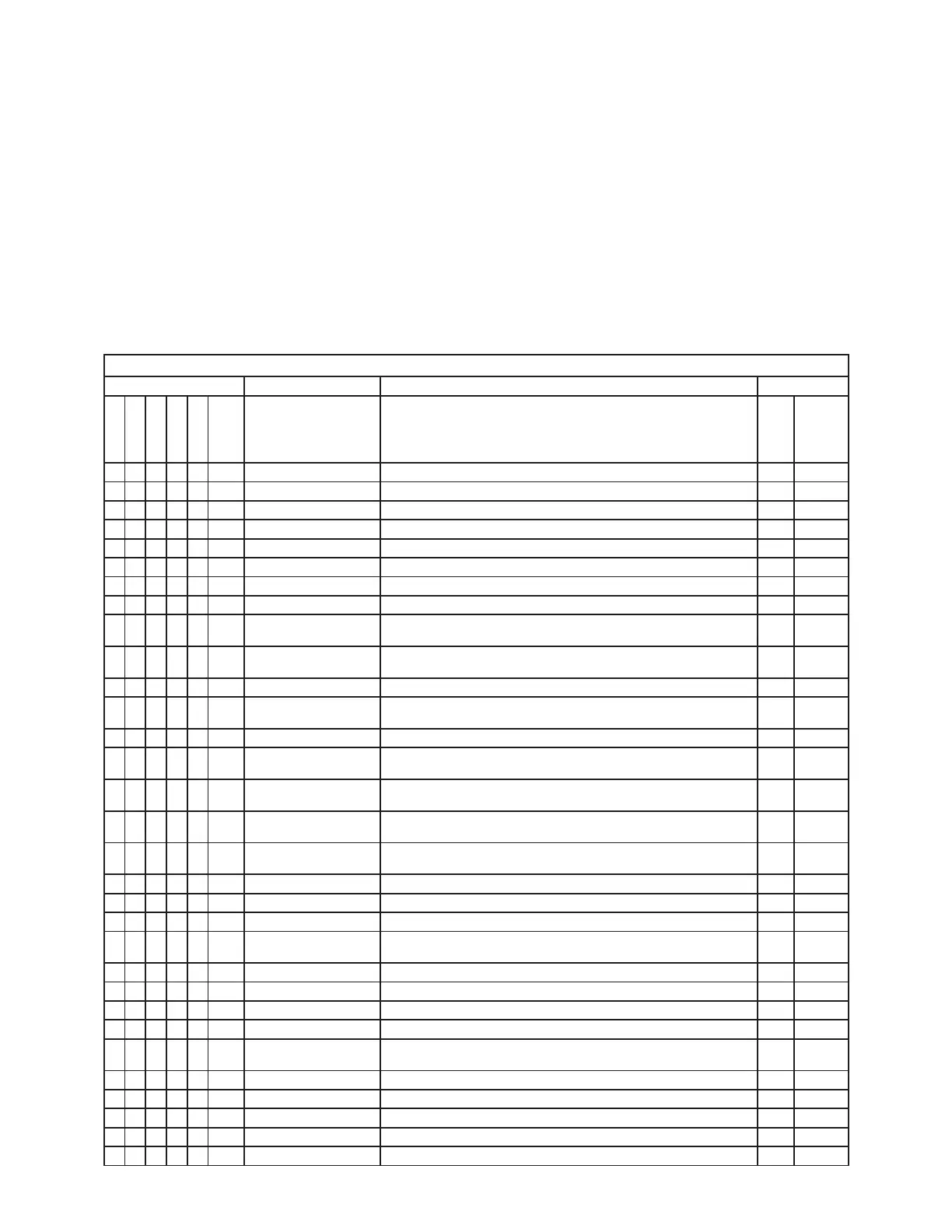

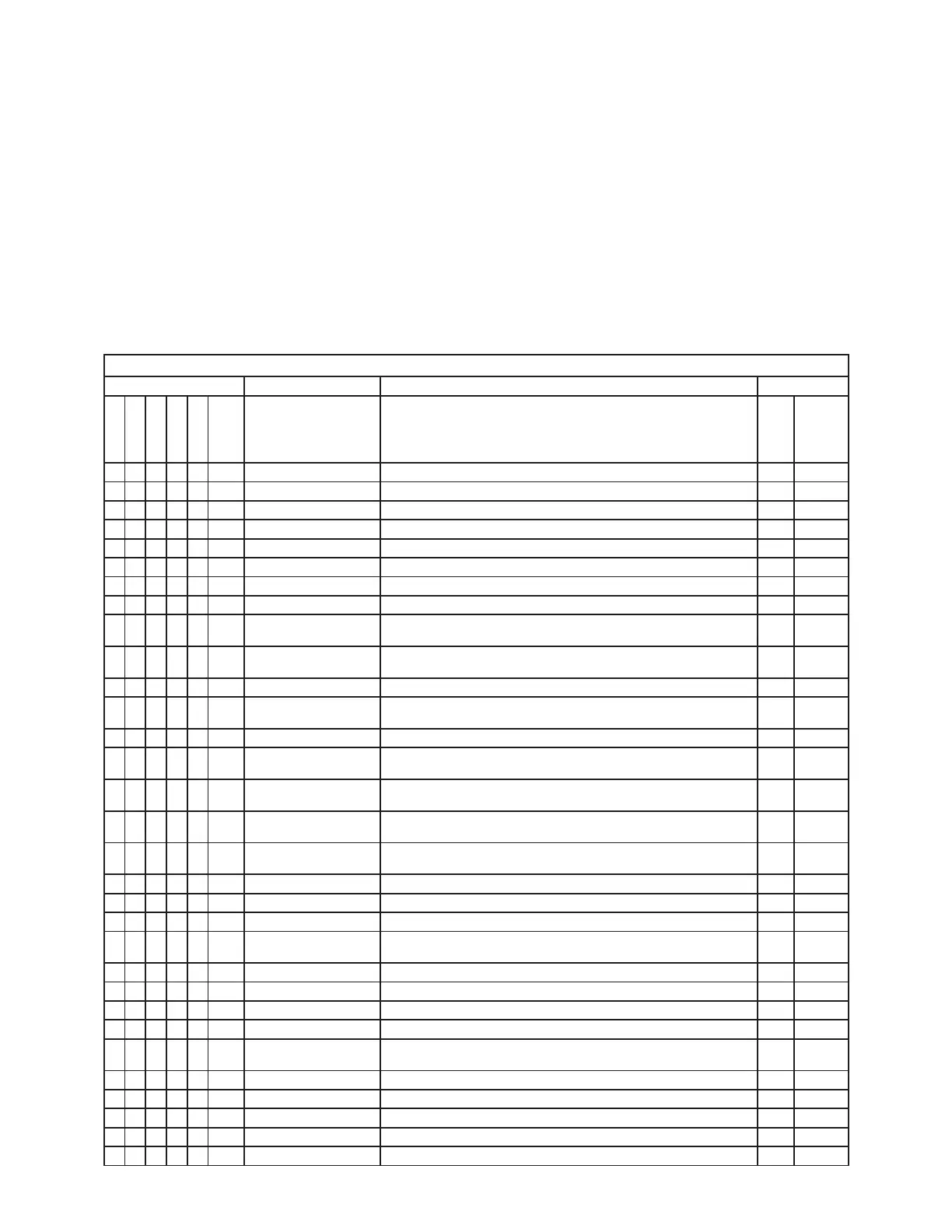

6 - Inspection and Maintenance Schedule

Frequency Performed By

Daily

Weekly

Monthly

Seasonal

Annual

Annual As

Required

Component / Item Recommended Action or Test

Boiler

Operator

Trained

Burner

Technician

X Burner Flame Visual inspection of burner ame. X

X Air Damper Visual inspection for smooth and free travel. X

X Fuel Metering Valves Visual inspection for smooth and free travel. X

X Draft Controls (Stack) Visual inspection for smooth and free travel. X

X Gas Fuel Pressure Record in log book, compare trends. X

X Oil Pressure Record in log book, compare trends. X

X Atomizing Air Pressure Record in log book, compare trends. X

X Pilot Visually inspect pilot ame, check and record ame signal strength if metered. X

X Flame SafeGuard - Pilot

Test

Close manual fuel valve on pilot during cycle and check for safety shutdown,

recording time.

X

X Flame SafeGuard - Main

Flame

Close manual fuel valve on pilot during cycle and check for safety shutdown,

recording time.

X

X Flame SafeGuard Check ame safeguard components, including scanner. X

X Flame SafeGuard Replace ame safeguard components in accordance with manufacturers

instructions.

X

X X Pilot Turndown Test Conduct pilot turndown test annually or after any component change. X

X X Hot Refractory Test Conduct hot refractory hold in test. This test is required annually or after any

component change.

X

X Oil Pressure and Tem-

perature Interlocks

Check oil pressure and temperature switch for smooth operation and correct

action.

X

X Atomizing Air Pressure Check air atomizing pressure interlock switch for smooth operation and cor-

rect action.

X

X Interlock Controls Check other interlocks that may be used on the burner for smooth operation

and correct action.

X

X Firing Rate Control Check ring rate control and verify settings. X

X Combustion Tuning Conduct a combustion test, verify setting and NOx emission levels. X

X Pilot and Main Fuel Valves Make visual and manual check for proper sequencing of valves. X

X Pilot and Main Fuel Valves Check all coils, diaphragms, interlock switch & other parts of all safety shutoff

valves.

X

X Pilot and Main Fuel Valves Perform leak tests on all safety shutdown control valves. X

X Low Pressure Air Switch Test low air pressure switch for proper operation and adjustment. X

X Mod Damper Switch Check damper low re proving switch per manufacturers instructions. X

X Combustion Air Fan Clean combustion air fan and housing X

X X

Burner Components Visually check the burner components for signs of cracks, deformation, slip-

page or other unusual indication.

X

X Burner Mounting Check burner mounting clamps and brackets for tightness. X

X Refractory and Seals Check burner refractory for cracks or signs of leakage. X

X Oil Nozzle Check and clean oil nozzle. X

X Air Compressor Check air compressor for lubrication oil and air lter. X

X Air Compressor Check air compressor relief valve operation. X

Loading...

Loading...