6 | WECM / Emerald eZA Manual

www.weg.net

5. INSTALLATION

DANGER!

g

Make sure the AC power supply is disconnected and protected against acciden-

tal energization before starting the installation;

g

Check the motor direction of rotation, turning it without load before it is coupled

to the load;

g

To prevent accidents, ensure that the grounding connection has been performed

according to the applicable standards and that the shaft key has been securely

fastened before the motor is started;

g

Do not lift and/or carry the product holding by the input cables.

Motors must be only installed in places compatible with their mounting features and in applications

and environments for which they are intended.

Those motors with feet must be installed on bases duly planned in order to prevent vibrations and

assure perfect alignment. The motor shaft must be properly aligned with the shaft of the driven

machine. Incorrect alignment, as well as improper belt tension, will certainly damage the bearings,

resulting in excessive vibrations and even causing the shaft to rupture. The admissible shaft radial

and axial loads for standard bearings are specified on the table below. Use flexible coupling when-

ever possible.

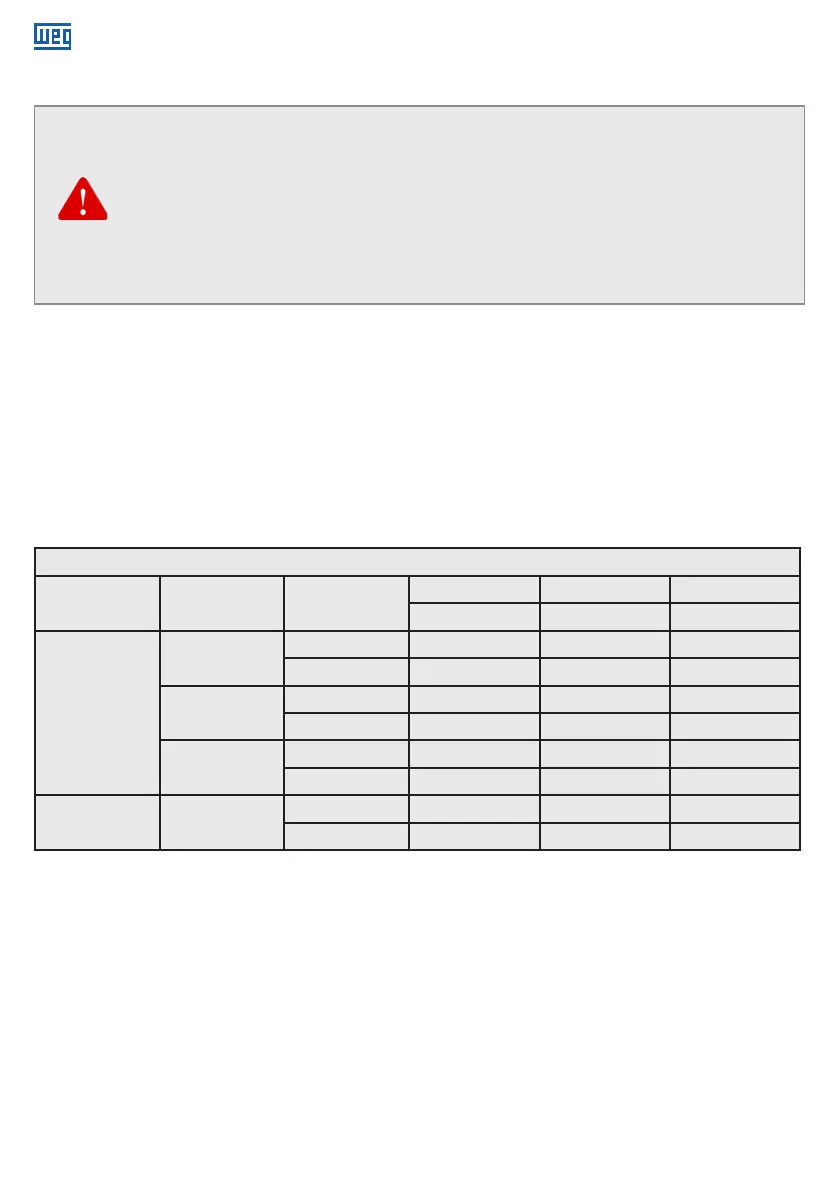

Maximum permissible thrust - Fr in (kN) 26280 hours

Direction

Mounting

position

Type

1500rpm 1800rpm 3000rpm

Force (kN) Force (kN) Force (kN)

Axial*

Horizontal

Pushing 0.31 0,29 0.25

Pulling 0.17 0.16 0.12

Vertical shaft

down

Pushing 0.35 0.33 0.27

Pulling 0.14 0.14 0.10

Vertical shaft

up

Pushing 0.27 0.27 0.23

Pulling 0.23 0.20 0.15

Radial** All

L 0.11 0.11 0.12

L/2 0.19 0.19 0.16

Table 1 - Allowed loads for Emerald eZA (NEMA 48) motors

Loading...

Loading...