Part Number: 2A33687

Release Date: 8/27/2015

Revision: B

47

Vessel Test Procedures:

Prior to shipment, product testing procedure 4S12497 requires that each emergency valve pass a one-time

vessel test at 150% it’s rated working pressure; then, when conducting subsequent vessel tests on used or re-

certified valves, limit the pressure to 100% of rated working pressure as required by 4S12497.

Emergency relief valves should always be vessel tested in accordance with product testing procedure 4S12497.

A fully assembled emergency relief valve should NEVER be pressure tested with the outlet discharge port.

A FULLY ASSEMBLED EMERGENCY RELIEF VALVE SHOULD NEVER BE PRESSURE TESTED

WITH THE OUTLET DISCHARGE PORT CAPPED OR BLOCKED OFF!

Below is an excerpt from 4S12497 regarding the proper vessel testing procedure on used emergency relief

valves:

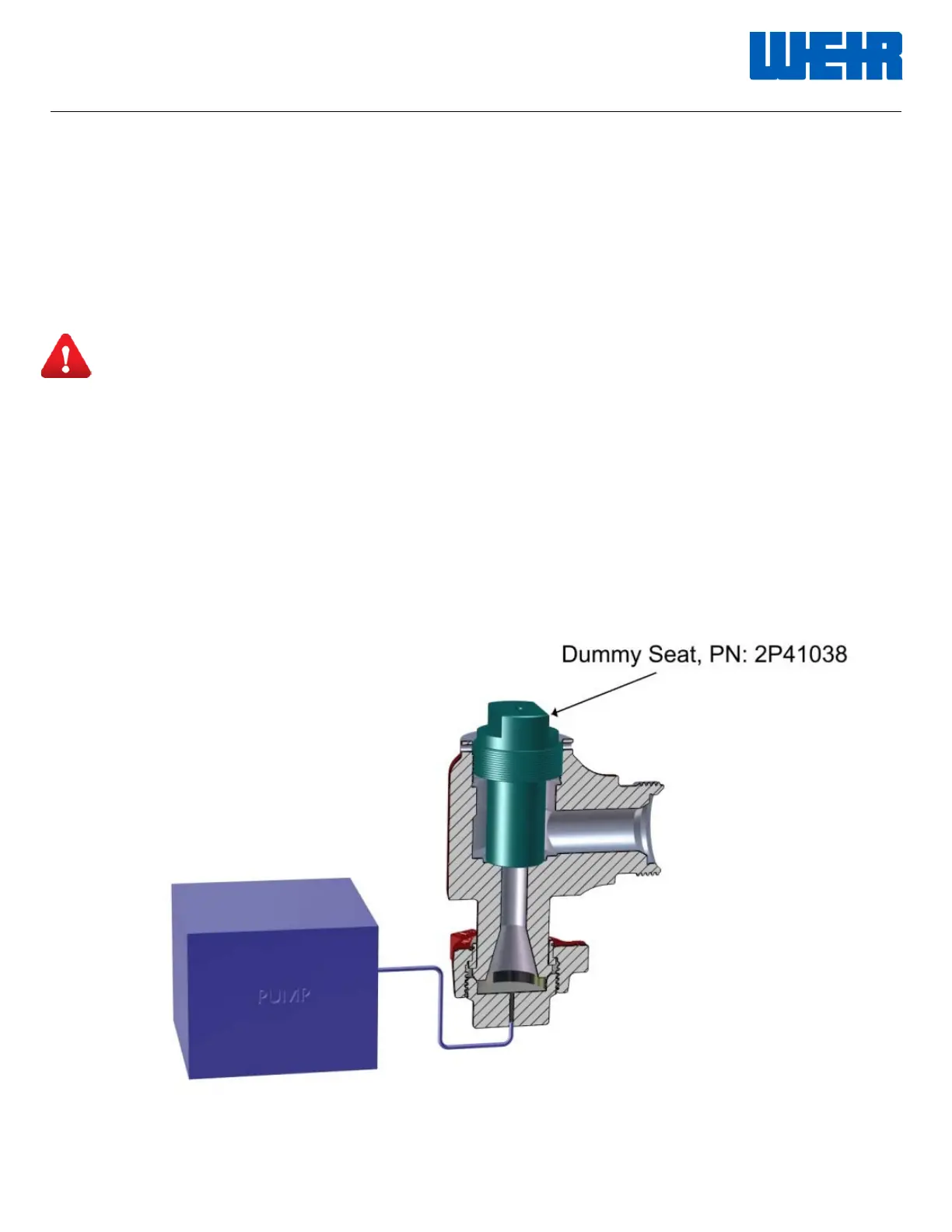

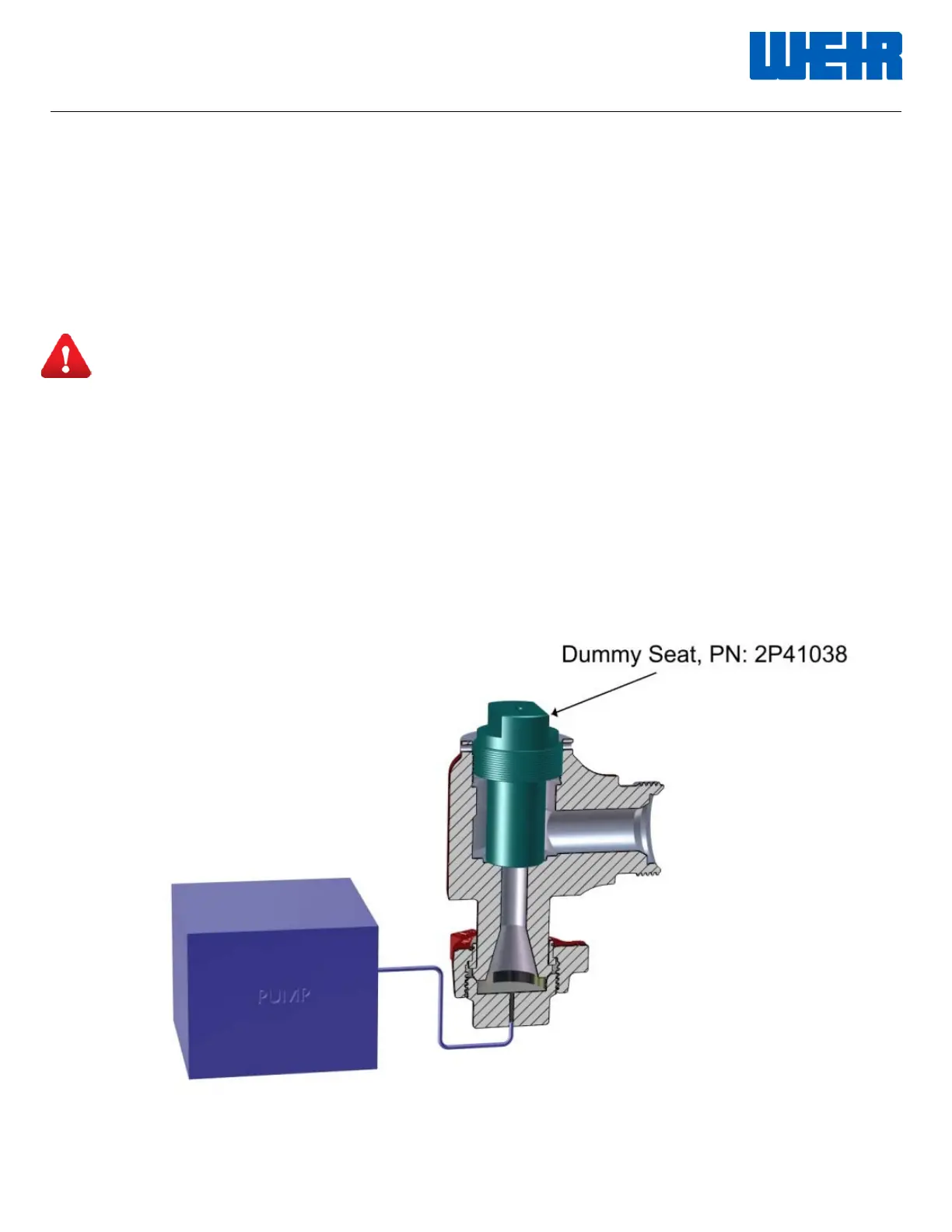

1. Assembly valve body with threaded blanking dummy seat (SPM

®

PN 2P41038) as shown here for

testing purposes only.

2. Attach valve to testing pump.

3. Fill with water and bleed off all air from the system prior to test.

4. Hydrostatically test by pressuring to 100% of product’s designed working pressure.

5. Hold pressure for the duration of time specified in 4S12497 spec.

6. Reduce pressure to zero.

Loading...

Loading...