Part Number: 2A33687

Release Date: 8/27/2015

Revision: B

49

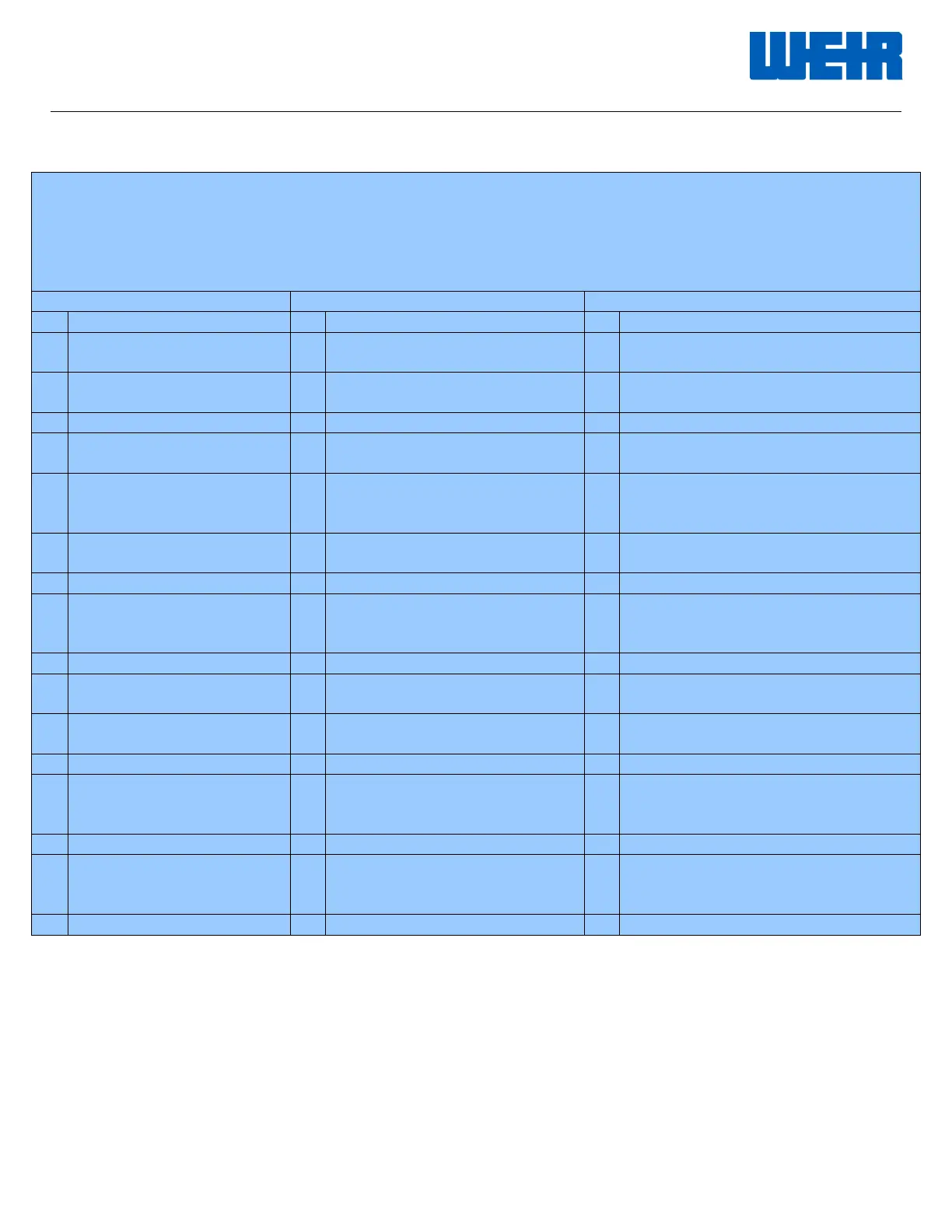

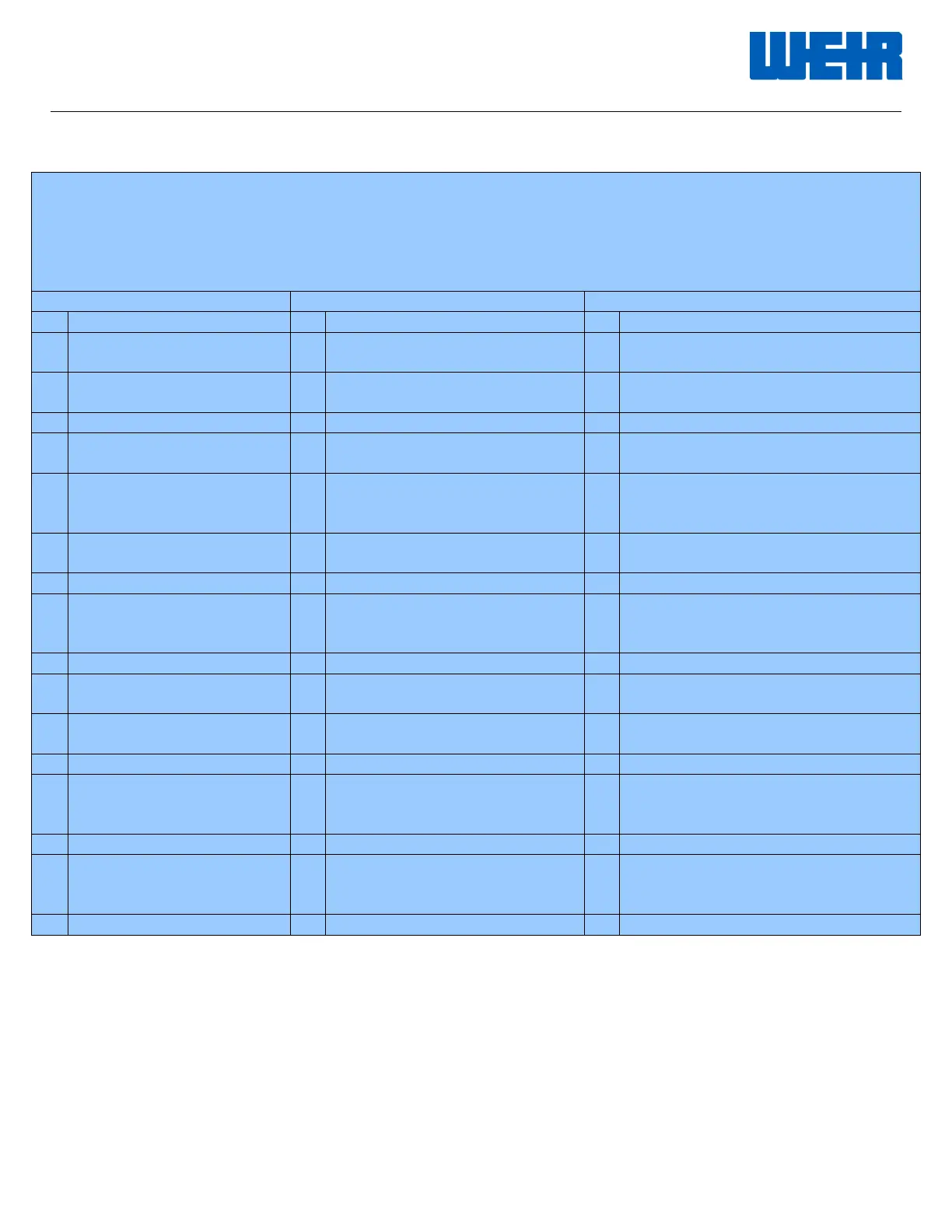

Troubleshooting Guide

Always follow existing Weir Oil & Gas procedures concerning identifying equipment for inspection, and removing

equipment from service. The following is intended as a general guide in helping resolve most problems

encountered in repairing emergency relief valves. If problems not covered here are encountered, contact Weir Oil

& Gas for assistance.

SYMPTOM PROBLEM SOLUTION

1. Rapid erosion a) Used as continuous bypass a) Use only as an emergency back

pressure relief device

b) Used beyond rated capacity b) Install sufficient quantity of valves to

meet capacity requirements

2. Shuddering (Rapid

opening and closing)

a) System pressure hovering at

set pressure

a) Raise set pressure slightly

b) Back pressure relief valve

located too close to pump’s

discharge

b) Relocate EXL Back Pressure Relief

Valve. Refer to service literature for

information on proper location.

c) Valve installed before pressure

dampener

c) Relocate relief valve behind pressure

dampener

3. Loss of pressure (Valve

does not seal or loses fluid

through discharge)

a) Valve not set properly a) Set valve correctly.

b) Damaged nozzle or valve gate b) Replace damaged parts

c) Damaged high pressure

cylinder connection

c) Replace damaged parts

d) Contaminants trapped between

valve gate and nozzle

d) Clean affected parts

4. Valve leaks through

weephole or between

valve body and cap

a) Damaged inner or outer or both

flange seals

a) Replace damaged seals

5. Valve releases higher or

lower than intended relief

pressure

a) Valve set incorrectly a) Reset valve to desired pressure per

instructions in Section II

Loading...

Loading...