Document P/N:

2P121260

Release Date: 02/27/2017

Revision: E

25 of 41

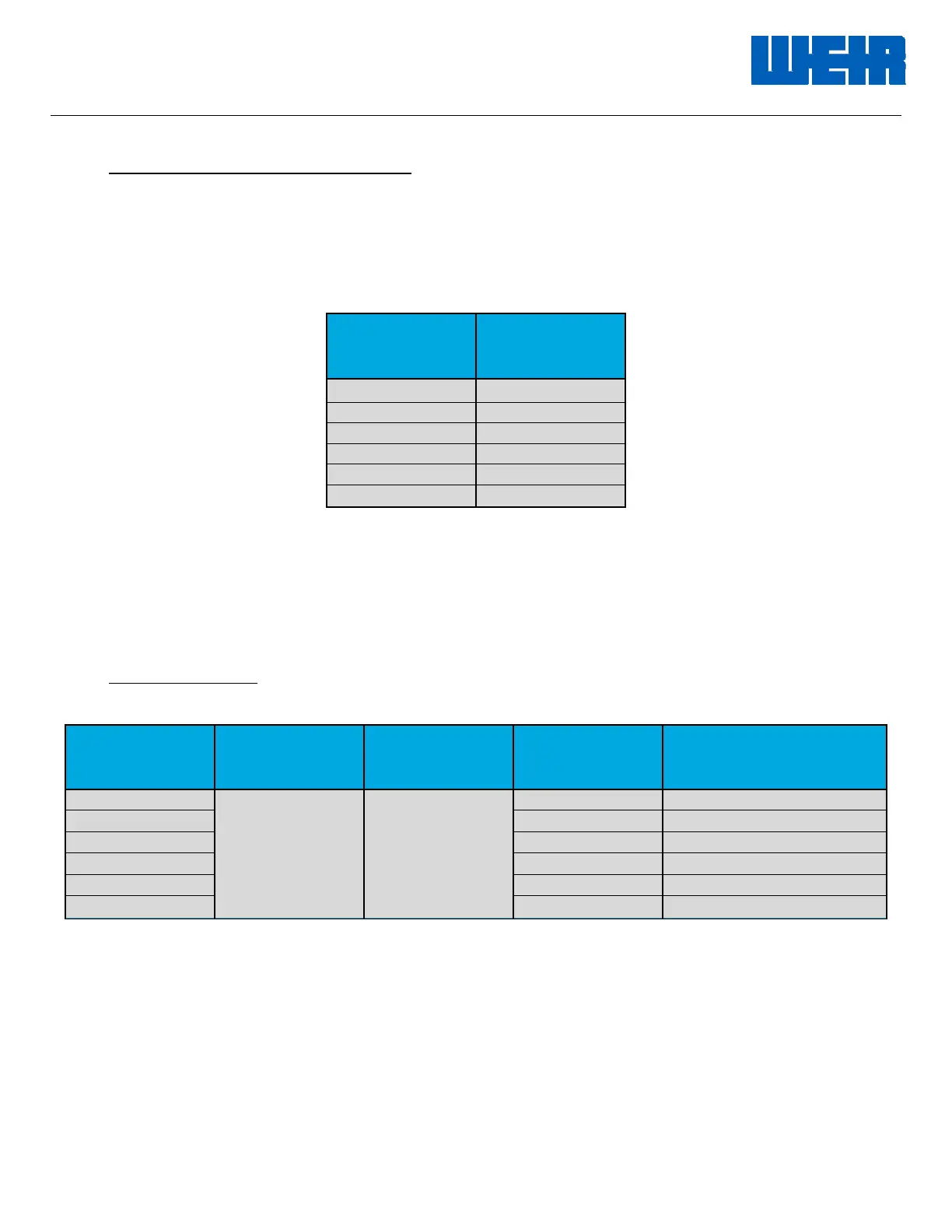

C. Plunger Pump Valve Seating Procedure:

1. In order to protect the fluid cylinder from washing before sustained pumping begins, the tapered

valve seats must be pressured up and fully seated creating a positive fluid seal.

2. Adjust the test choke for high pressure/low pump RPM. Shift the transmission to 1st gear and

slowly increase the throttle setting, to achieve the values in the table below, for 2 to 3 minutes or

until a series of audible popping noises are heard. This indicates the seats have properly set in

the taper. The desired pressure for each plunger size is as follows:

PLUNGER

DIAMETER

IN (MM)

SEATING

PRESSURE

PSI (MPA)

2 1/2 (63.5)

9,400 (64.8)

2 3/4 (69.9)

9,400 (64.8)

3 (76.2)

9,400 (64.8)

3 1/2

(88.9)

4,600 (31.7)

4 (101.6)

4,600 (31.7)

4 1/2 (114.3)

4,600 (31.7)

During this portion of the startup procedure, closely observe the plunger pump for any unusual

noise, vibration, fluid leaks, and oil leaks. Record all pertinent information such as elapsed time,

ambient temperature, power end lube oil temperature, power end lube oil pressure, supercharge

pressure, etc. After returning the engine to idle and transmission to neutral, physically inspect the

plunger pump before proceeding further.

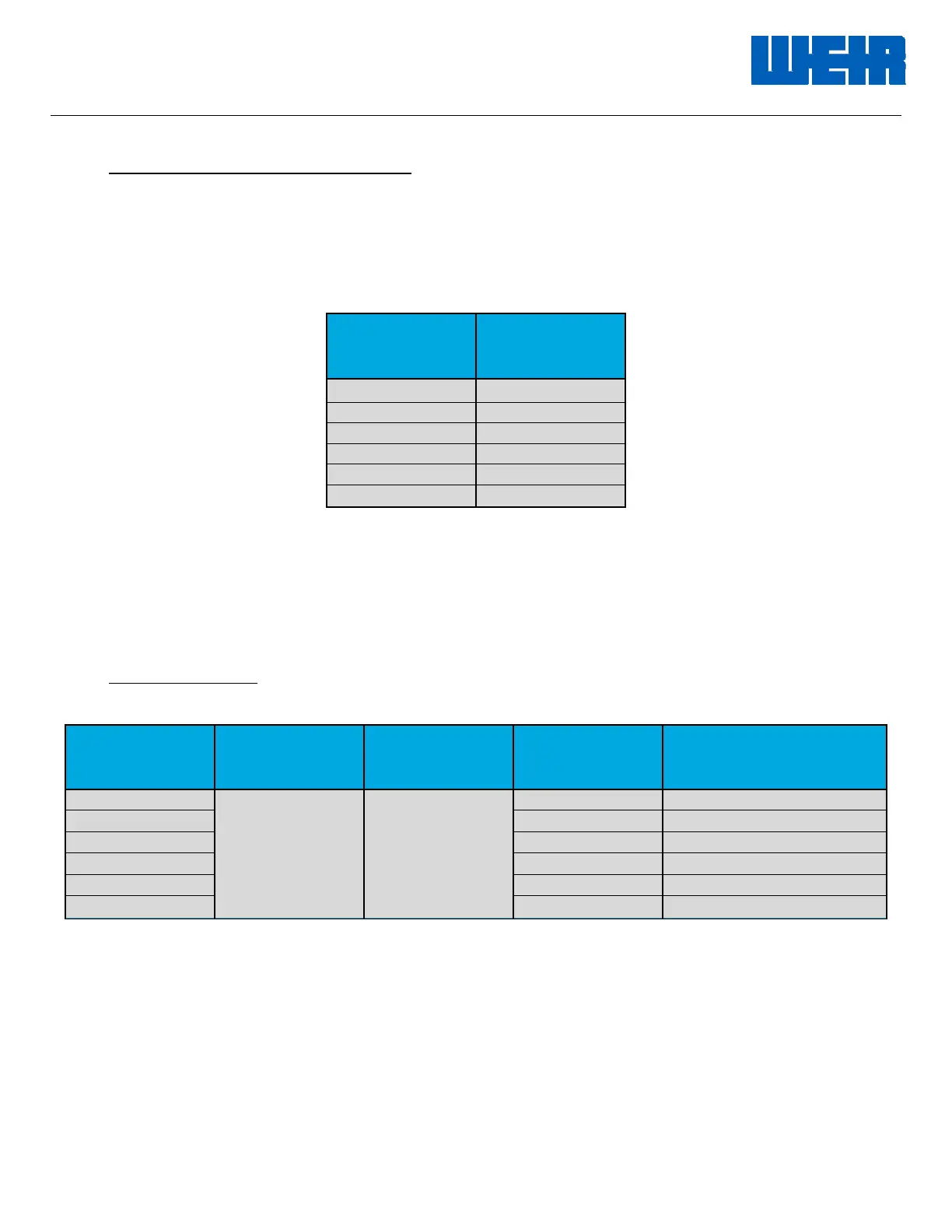

D. Break-In Procedure:

1. Adjust the test choke, engine, and transmission according to the values below. These settings

should be approximately as follows:

PLUNGER

DIAMETER

IN (MM)

INPUT SPEED

PINION PUMP

RPM

POWER

BHP KW

PRESSURE

PSI MPA

FLOW RATE

GPM BPM LPM

2 1/2 (63.5)

1400 304 270 201.3

3586 24.7 116 2.8 440

2 3/4 (69.9)

2963 20.4 141 3.3 532

3 (76.2)

2490 17.2 167 4.0 633

3 1/2 (88.9)

1829 12.6 228 5.4 862

4 (101.6)

1401 9.7 297 7.1 1126

4 1/2 (114.3)

1107 7.6 376 9.0 1425

Run the plunger pump at this setting for one hour. During this time, closely observe the plunger

pump for any unusual noise, vibration, fluid leaks, and oil leaks. Record all pertinent information

such as elapsed time, ambient temperature, power end lube oil temperature, power end lube oil

pressure, supercharge pressure, etc. After returning the engine to idle and the transmission to

neutral, physically inspect the plunger pump before proceeding further.

Loading...

Loading...