ASSEMBLY & ADJUSTMENTS

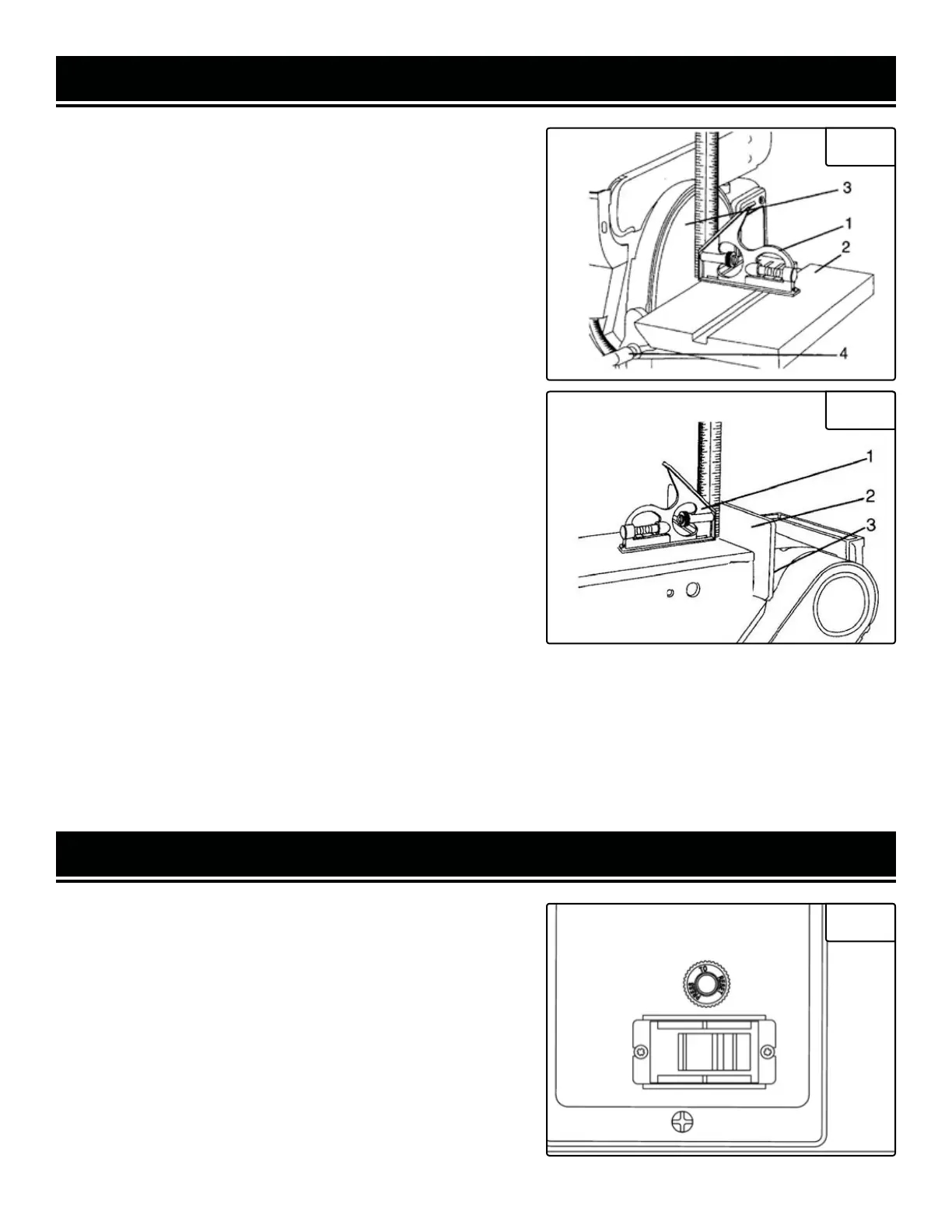

SQUARING THE TABLE

To ensure accurate end sanding, the work table (Fig. 10 - 2)

must be square to the sanding surfaces prior to using the tables

for disc sanding.

1. Adjust the table to be 90° with the sanding surface.

2. Using a combination square (Fig. 10 - 1), place one end on

the table with the ruler end against the sanding surface (Fig. 10

- 3). Check that the table is 90° to the sanding surface.

3. If the table is not 90° to the sanding surface, loosen the han-

dle (Fig. 10 - 4), adjust the table, tighten the handle and recheck

with the square.

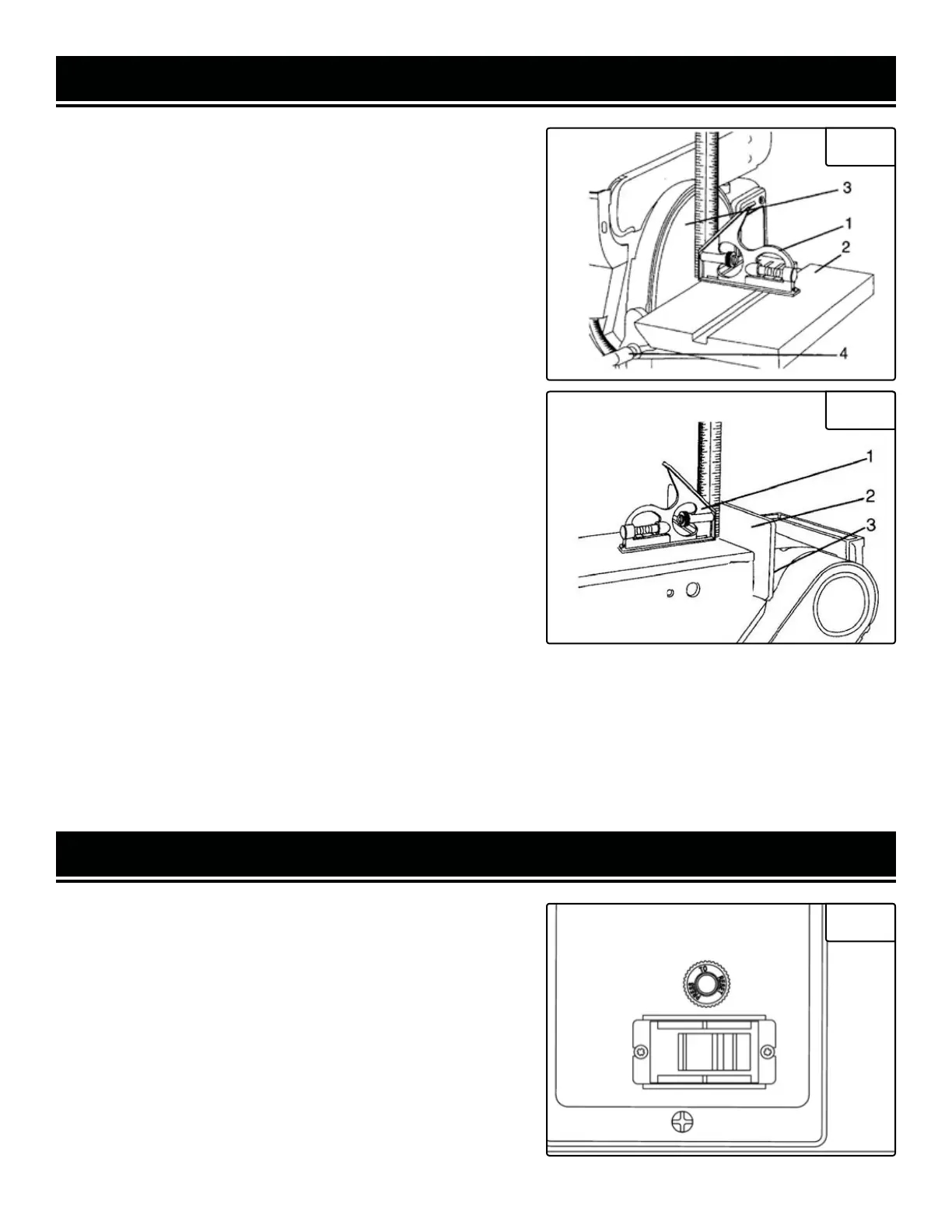

SQUARE THE WORK SUPPORT

The work support (Fig. 11 - 2) must be square to the sanding

belt when using the belt sander in a horizontal position. To keep

the workpiece from being carried along the belt:

1. Make sure the sanding belt is tight; also check that the ten-

sion lever is fully tightened.

2. Place the combination square (Fig. 11 - 1) on the belt with the

ruler against the work support (Fig. 11 - 2).

3. Adjust by loosening the work support locking screw (Fig. 11

- 3), square the work support.

4. Tighten the work support locking screw (Fig. 11 - 3).

Fig. 10

Fig. 11

OPERATION

CIRCUIT BREAKER

To protect the motor, your sander is equipped with a circuit

breaker, located on the right side of the unit near the power

switch. If the motor is overloaded, the circuit breaker will trip.

To reset the breaker, wait a moment and then press it in to reset

it. Do not press too hard on the sandpaper, or the motor may

overload.

Fig. 12

13

Loading...

Loading...