18

MAINTENANCE

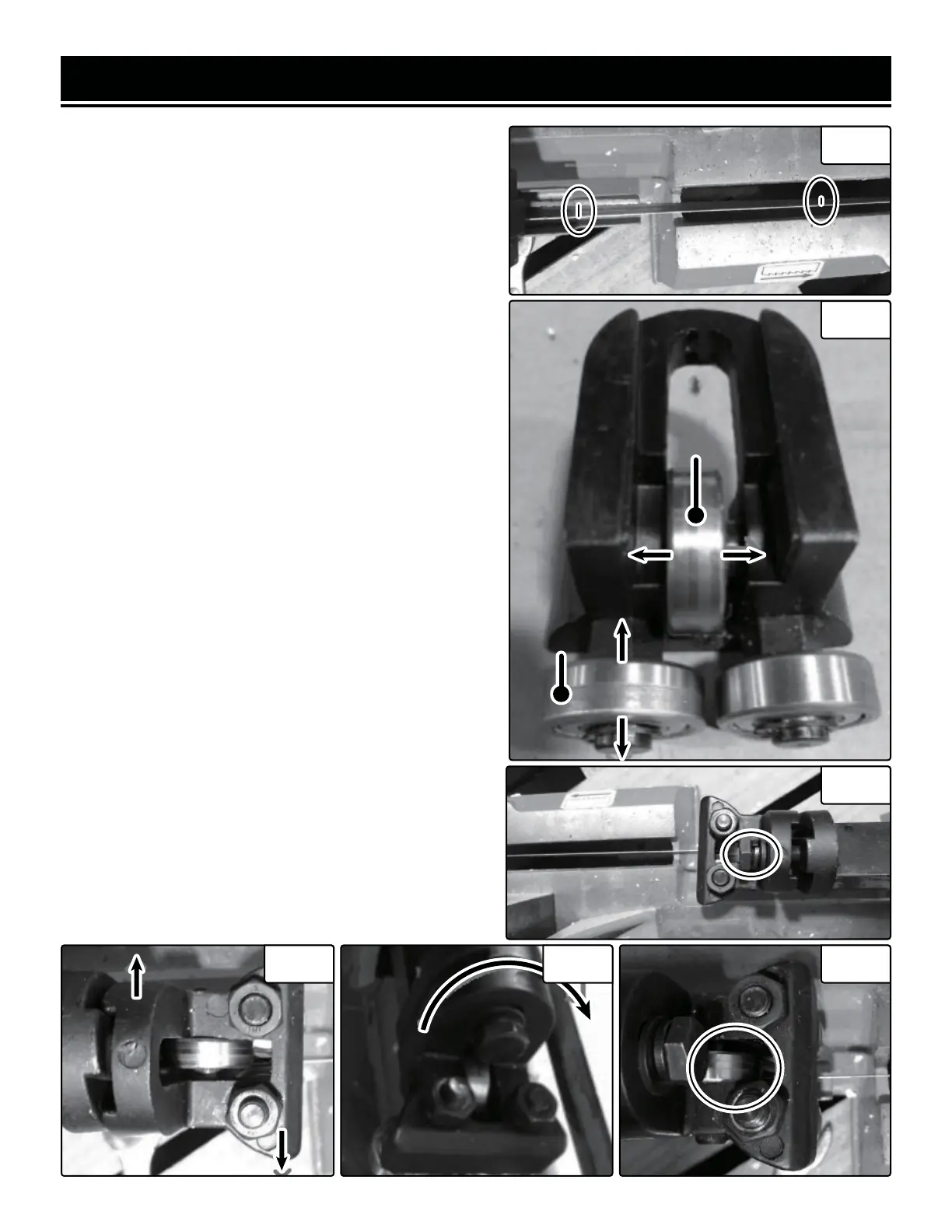

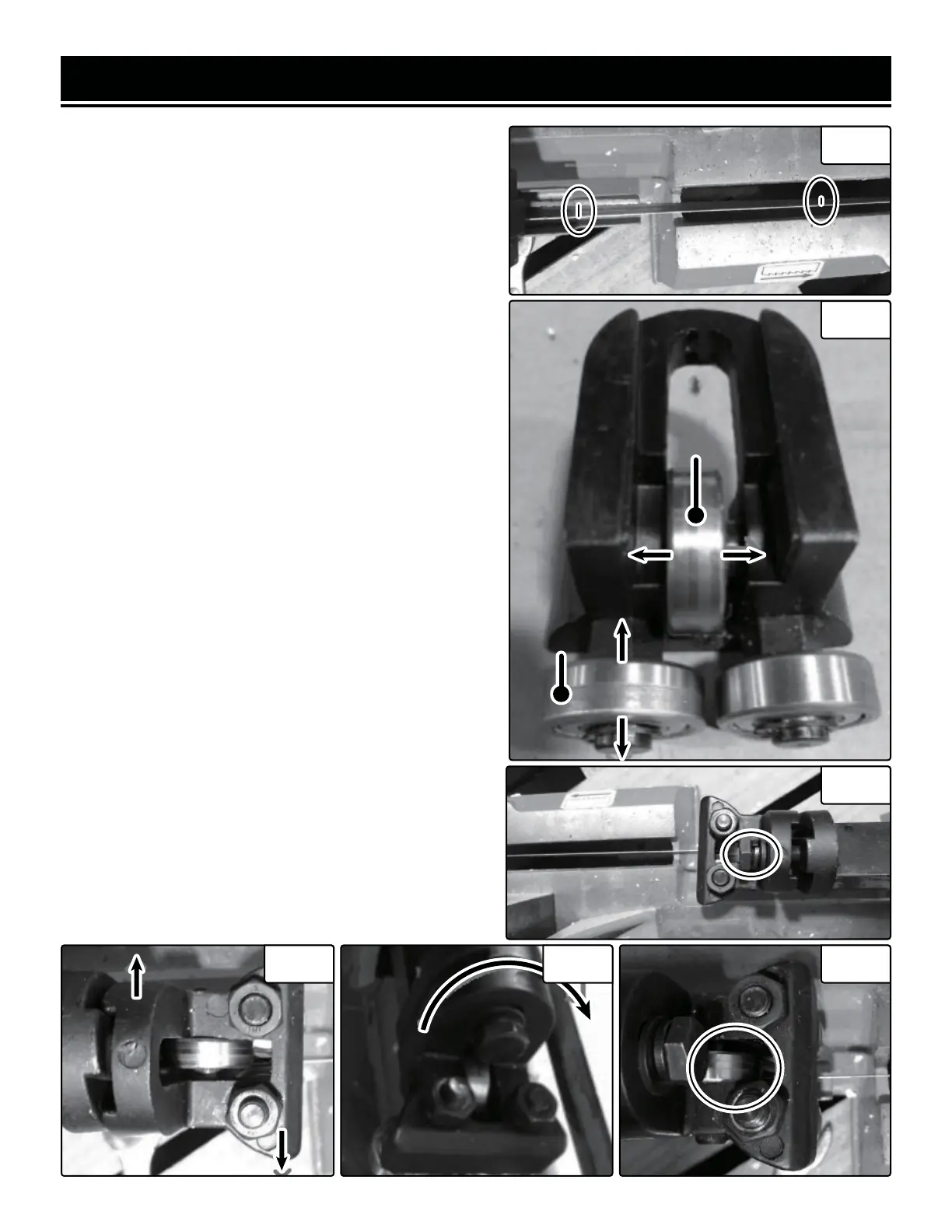

BLADE ALIGNMENT

Check Blade tension:

1. Remove the black back cover and make sure the blade is

properly aligned on both wheels.

2. Adjust the blade tension until the blade sits properly cen-

tered (or does not move) on both wheels during operation

Check Blade Guard:

Without the left blade guard, there is a twist on the blade

due to the way it sits on the two wheels and how it is as-

sembled. This is unavoidable (Fig. 27).

Blade Guard:

Arrows show the direction the bearings can be adjusted.

Using the Blade Guard to Straighten the Blade:

1. Loosen the nut on the left blade guard (Fig. 29).

2. Adjust the blade guard (Fig. 30).

The rear bearing will be in contact with the blade (Fig. 31).

NOTE: It is important to twist/adjust the blade guard in the

direction as shown in figure 30. Because of how the blade

is positioned on the wheels, this will help prevent the blade

from sliding off of the wheel during operation.

3. Adjust the thrust bearing so that it is in contact with the

blade (Fig. 32).

NOTE: If the blade still continues to slip off the wheels,

check if the right blade guard is causing any unnecessary

twist on the blade.

Fig. 27

Fig. 28

THRUST BEARINGTHRUST BEARINGTHRUST BEARING

SIDE

SIDE

BEARINGBEARING

SIDE

BEARING

Fig. 29

Fig. 30 Fig. 31 Fig. 32

Loading...

Loading...