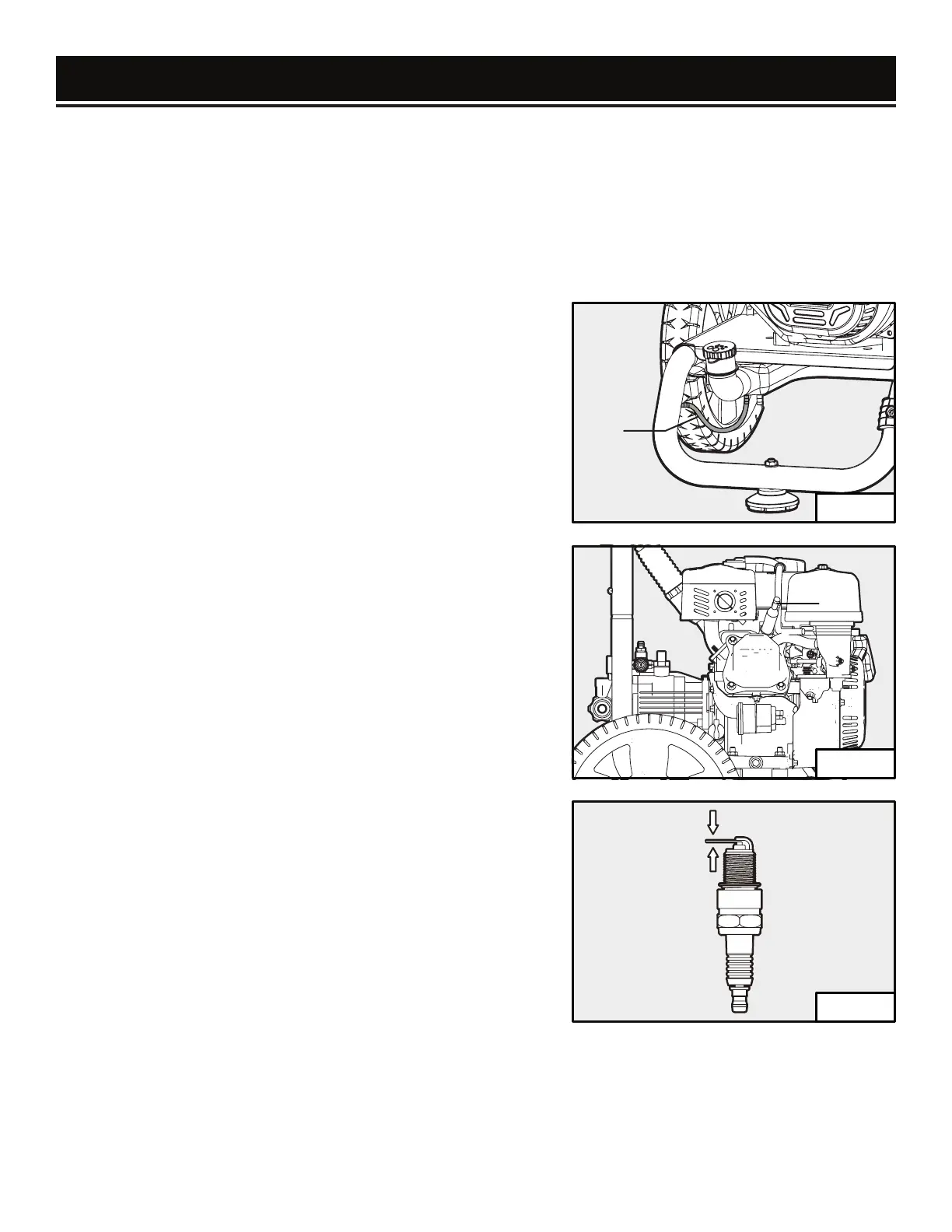

DRAINING THE SOAP (FIG. 17)

To drain the soap, unplug the hose highlighted in Figure 17

(Fig. 17 - 1). Use a container to hold the draining soap. Once

the soap is done draining, reconnect the hose.

SPARK PLUG MAINTENANCE

The spark plug is important for proper engine operation.

A good spark plug should be intact, free of deposits, and

properly gapped. Refer to Recommended Maintenance

Schedule.

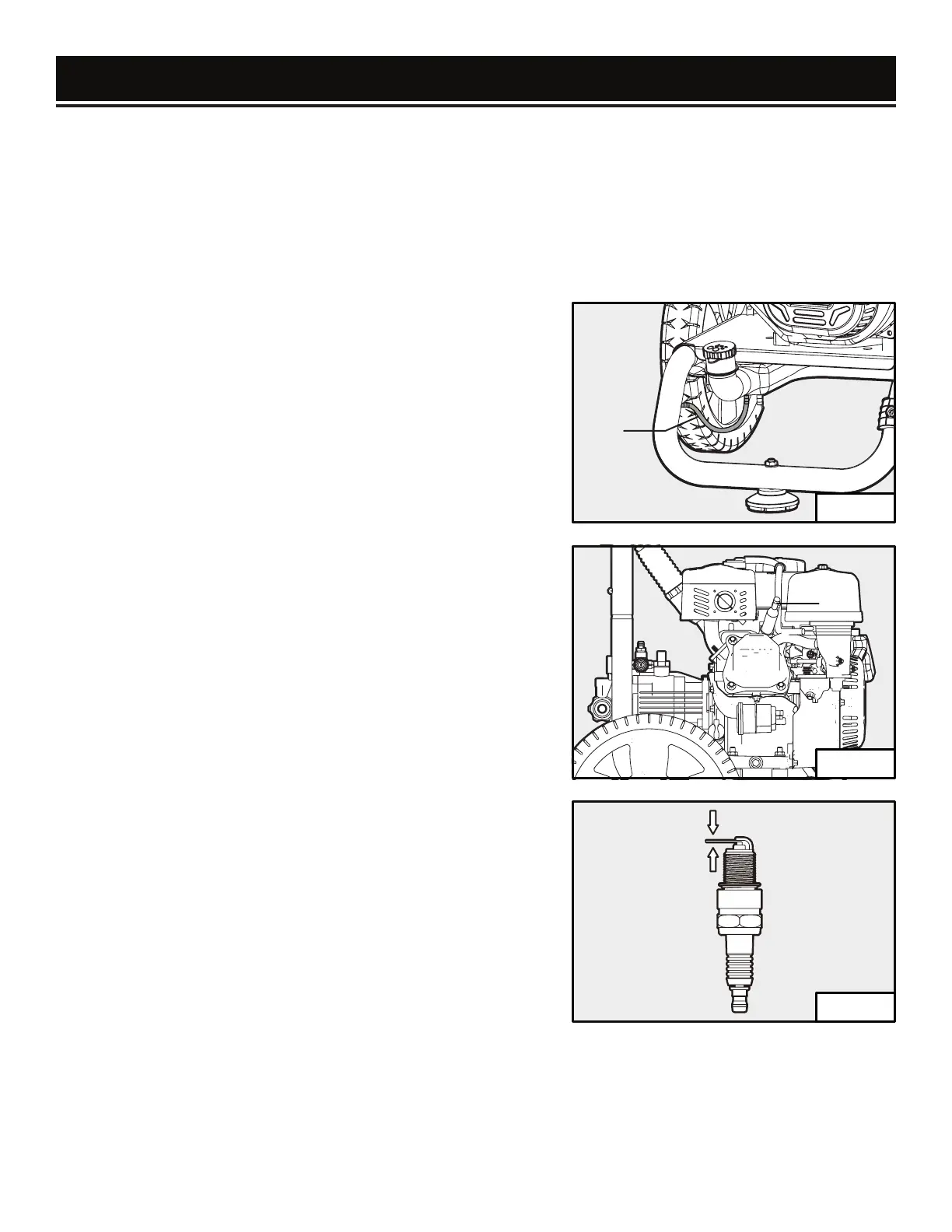

TO INSPECT THE SPARK PLUG (FIG. 18 & 19):

1. Remove spark plug boot (Fig. 18 - 1). Be careful not to

tear insulation or wiring.

2. Unscrew the spark plug from the engine using a spark

plug wrench. There is limited space for the wrench to turn.

Use both rows of holes in the spark plug wrench to gain

leverage to loosen the plug.

3. Visually inspect the spark plug for cracks or excessive

electrode wear. Replace as necessary.

4. Measure the plug gap with a wire gauge. The gap should

be 0.7-0.8 mm (0.028-0.031 in). (Fig. 19)

5. If re-using the spark plug, use a wire brush to clean any

dirt from around the spark plug base then re-gap the spark

plug.

6. Screw the spark plug back into the spark plug hole using

the spark plug wrench. Do not over-tighten spark plug.

Recommended tightening of spark plug is ½ to ¾ of a turn

after the spark plug gasket contacts the spark plug hole, or

20 ft-lb. Reinstall the spark plug boot.

Fig. 17

1

Fig. 18

1

Fig. 19

0.7 - 0.8 mm

MAINTENANCE

3. Unscrew the carburetor drain plug to drain the carburetor (Fig. 20). Be sure to drain the carburetor

so the machine can funtion properly for the next use.

4. Re-attach the fuel line to the exposed end of carburetor.

CAUTION: Do not dispose of the fuel in general waste. Make sure to collect it and take the fuel to your

local recycling center. Do not store fuel for more than 3 months.

19

Loading...

Loading...