PREPARATION

FOR

STARTING

This

section of the

manual

provides the operator

with

preparation,

initial starting,

break-in,

starting

(cold or

warm),

and

stopping procedures. Follow the procedures

as

presented,

for the conditions indicated,

and

your

Westerbeke

engine

set

will

give you reliable

performance

and

long

service

life.

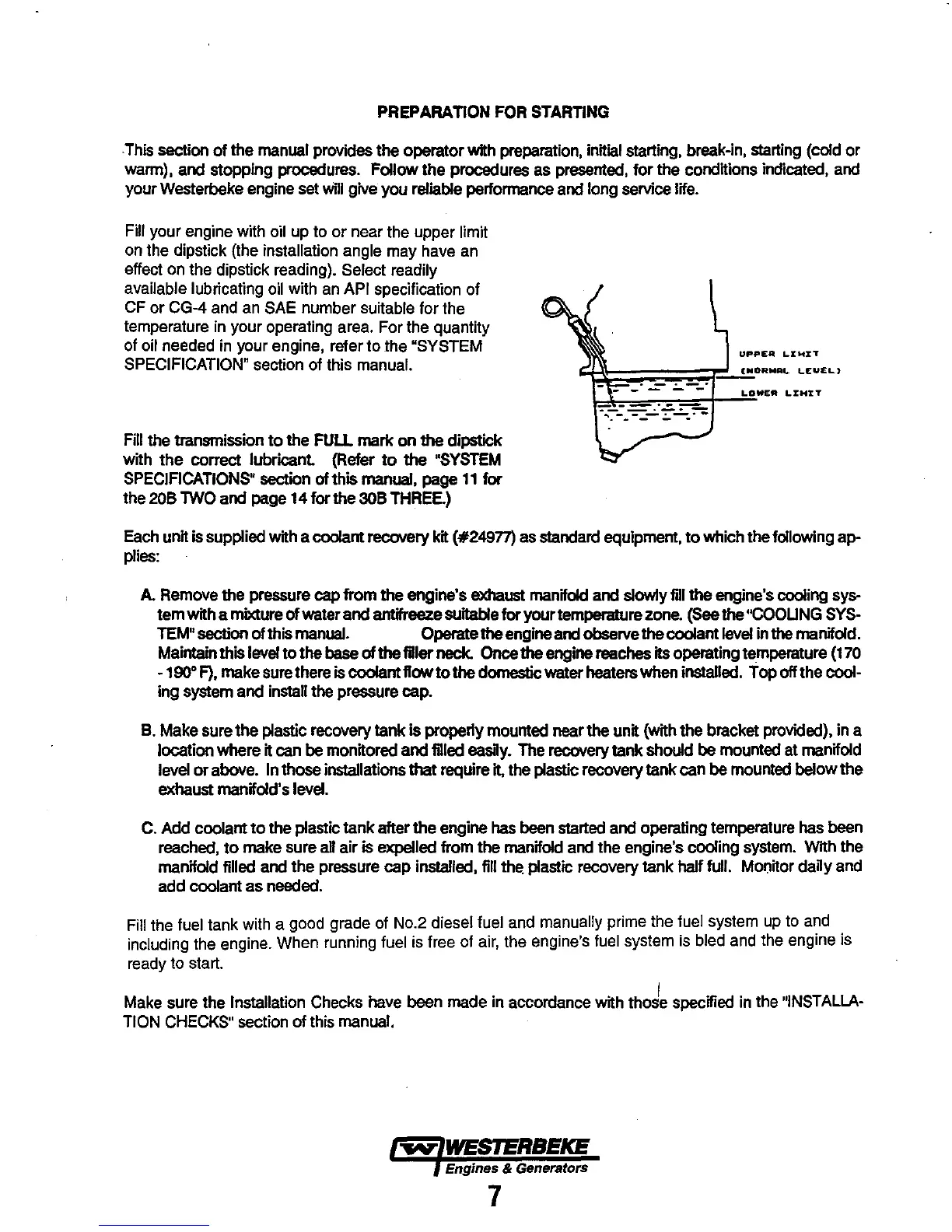

Fill

your engine

with

oil

up

to

or

near

the

upper limit

on

the dipstick

(the

installation angle

may

have

an

effect

on

the

dipstick reading). Select readily

available lubricating

oil

with

an

API

specification of

CF

or

CG-4

and

an

SAE

number suitable for the

temperature

in

your operating

area.

For

the

quantity

of

oil

needed

in

your

engine, refer to the ·SYSTEM

SPECIFICATION"

section of this

manual.

Fm

the transmission to the

FUll

mark on the dipstick

with the correct

lubricant

(Refer

to

the

"SYSTEM

SPECIFICATIONS"

section

of

this

manual,

page

11

for

the

206

TWO

and

page

14

for the 306

THREE.)

UPPER

L:lIoot:lT

'1;~_;;;;;_,;:;_;;:_;:;:,:",;::_;_;;:,

r-

(NORMAL

LEVEL)

1d.....,=-:-::-=rl_~L""OWER

L:lNt:T

Each

unit is supplied with a coolant recovery kit (#24977)

as

standard

equipment,

to which the following ap-

plies:

A.

Remove

the pressure cap from the engine's exhaust

manifold

and

slowly fill the engine's cooling

sy&-

tem with a mixture of

water

and antifreeze suitable for your temperature

zone.

(See

the

"COOUNG

SYS-

TEM"

section of this

manual.

Operate the

engine

and observe the coolant

level

in

the manifold.

Maintain this

level

to the

base

of the filler

neck.

Once

the

engine

reaches

its operating temperature

(170

-

190°

F),

make

sure

there

is

coolant flowto the domestic water heaters when installed. Top off the cool-

ing

system

and

install

the

pressure cap.

B.

Make

sure

the plastic recovery tank is properly

mounted

near

the unit (with the bracket

provided),

in

a

location where it

can

be

monitored and filled easily.

The

recovery tank should

be

mounted

at

manifold

level

or

above.

In

those installations that require

It,

the

plastic recovery tank

can

be

mounted

below the

exhaust manifold's

level.

C.

Add coolant

to

the plastic tank after the engine

has

been

started

and operating temperature

has

been

reached,

to

make

sure

all

air is expelled from the

manifold

and

the engine's cooling

system.

With

the

manifold filled

and

the

pressure

cap installed, fill the plastic recovery tank half full.

MOlJitor

dany

and

add coolant

as

needed.

Fill

the

fuel

tank

with

a

good

grade

of

No.2

diesel

fuel

and

manually

prime

the

fuel

system

up

to

and

including

the

engine.

When

running

fuel

is

free

of

air,

the

engine's

fuel

system

is

bled

and

the

engine

is

ready

to

start.

Make

sure

the Installation

Checks

have

been

made

in

accordance with thoJe

specified

in

the

"INSTALLA-

TION

CHECKS"

section of

this

manual.

Engines & Generators

7

Loading...

Loading...