The charging system consists of

an

alternator with

an

internal

voltage

regulator,

an

engine-mounted circuit

breaker,

a battery and connecting wires.

Because

of the use of IC's (integrated circuits), the

eleCtronic

voltage

regulator

is very compact

and

is built

into

the

rear

bracket of the alternator.

Charging

Voltage

Test

If you suspect that the alternator is not producing

enough

voltage to

charge

the engine's battery,

perform

the following voltage test.

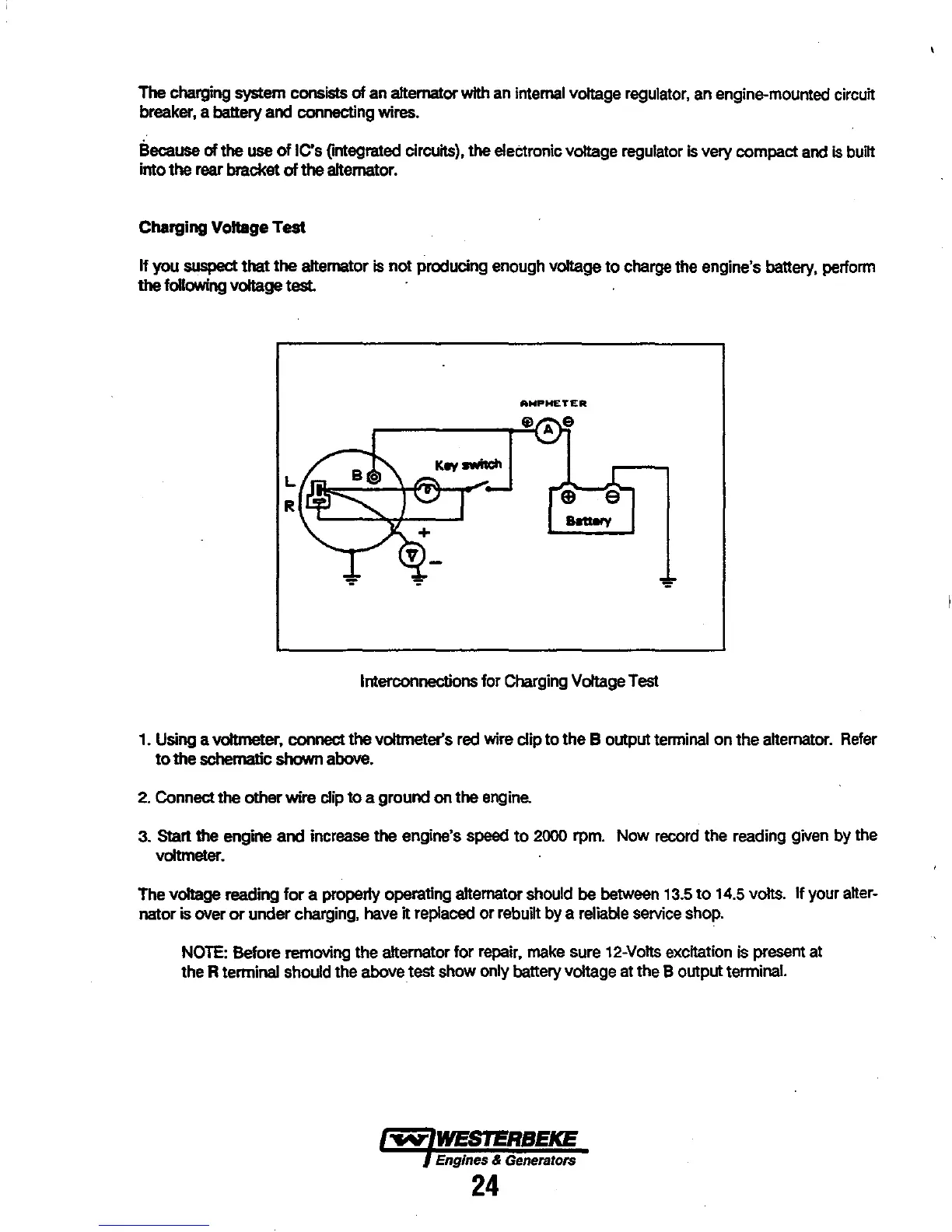

ANPHETER

r-

__________

~e{A

e

Interconnections for

Charging

Voltage

Test

1.

Using

a voltmeter, connect the voltmeter's

red

wire

dip

to the B output

terminal

on the

alternator.

Refer

to

the

schematic

shown

above.

2.

Connect the other wire dip to a ground

on

the

engine.

3. Stan the engine and increase the engine's

speed

to

2000

rpm. Now

record

the reading

given

by

the

voltmeter.

The voltage reading for a properly operating alternator

should

be

between

13.5

to

14.5

volts. If your

alter-

nator is

over

or

under charging,

have

it replaced or rebuilt by a

reliable

service

shop.

NOTE:

Before removing the alternator for

repair,

rnake

sure

12-Volts

excitation

is

present

at

the R terminal should the above test show only battery voltage

at

the B output terminal.

Engines & Generators

24

Loading...

Loading...