Servicing After Every

800

Hours

01

Operation

*1.

Remove

and check

fuel

injectors.

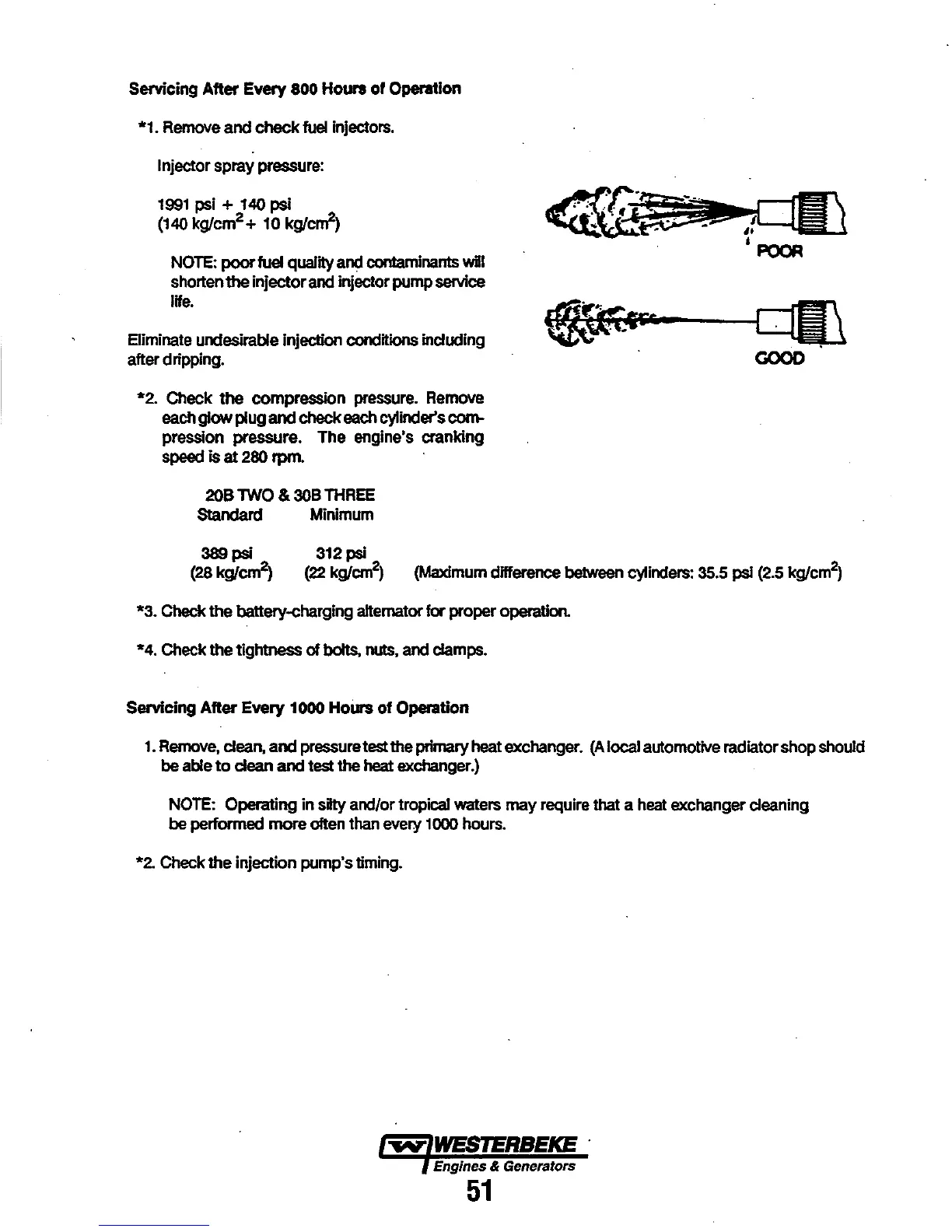

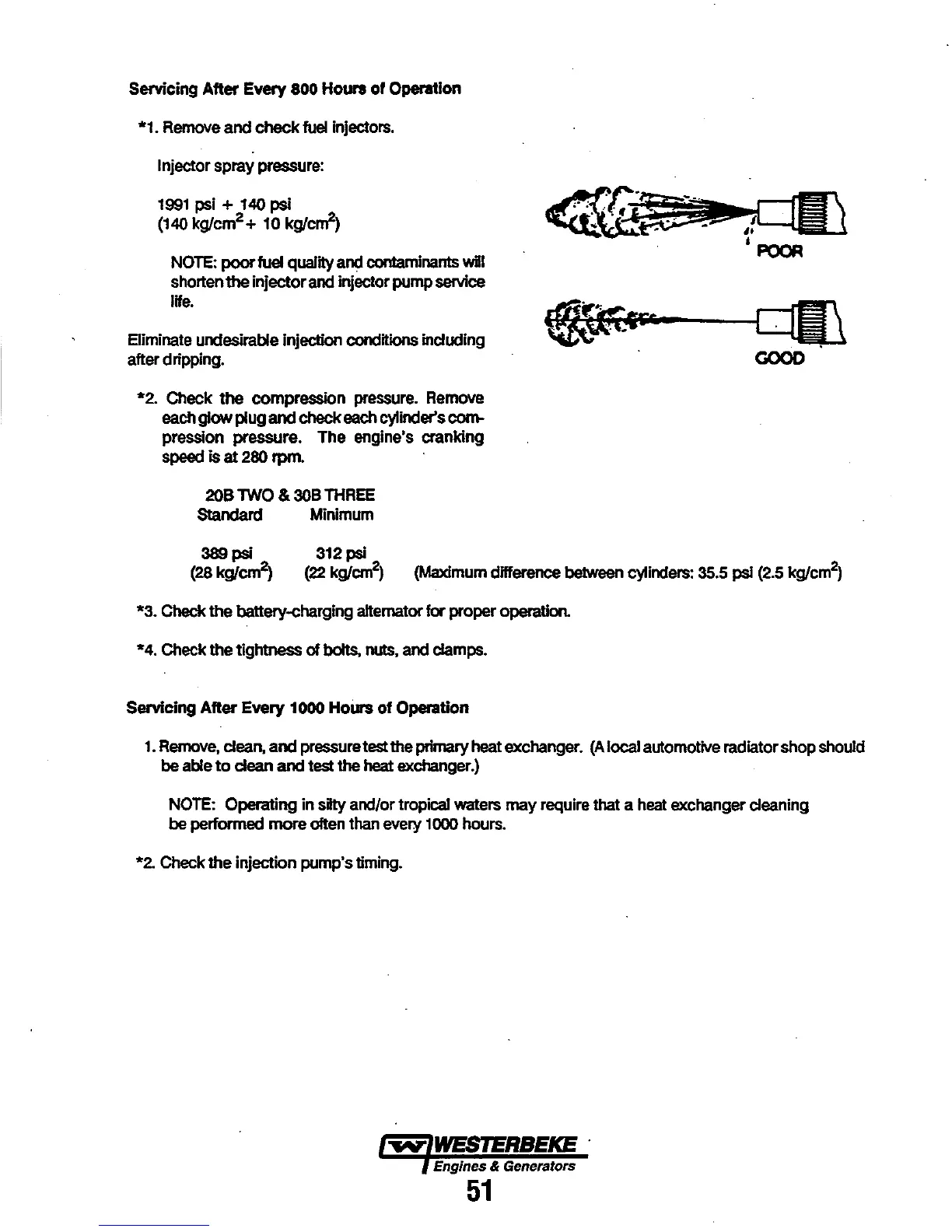

Injector spray pressure:

1991

psi

+

140

psi

(140 kglcm

2

+

10

kglcrif)

I.

I

POOR

NOTE:

poor fuel quality and

contaminants

will

shorten

the

injector and injector

pump

service

life.

Eliminate

undesirable injection conditions including

after dripping.

Qe~f:tf~!Ori.

:115

5

,,","

--Wiii

COOl)

*2. Check the compression

pressure.

Remove

each

~rNi

plug and

check

each

cylinder's

c0m-

pression pressure. The engine's cranking

speed

is at

280

rpm.

20B

TWO

&

30B

THREE

Standard

Minimum

389 psi

(28kglcm;

312

psi

(22

kglcm

2

)

(Maximum

difference

between

cylinders:

35.5

psi

(2.5

kglcm

2

)

*3. Check

the

battery-charging

a1temator

for proper operation.

*4.

Check

the tightness

of

bolts.

nuts, and

clamps.

Servicing After Every

1000

HoUrs

01

Operation

1.

Remove,

clean,

and

pressure

test

the

primary

heat

exchanger.

(A

local automotive radiator

shop

should

be

able

to

clean and test

the

heat

exchanger.)

NOTE:

Operating in silty and/or tropical waters may require that a

heat

exchanger cleaning

be

performed more

often

than

~ery

1000

hours.

*2.

Check

the injection pump's timing .

..-v'

WESTERBEKE

Engines & Generators

51

Loading...

Loading...