Piston

and

Connecting

Rod

Removal

1.

Remove the cylinder head assembly.

2.

Remove the oil pan.

3.

Remove the oil screen.

4.

Chalk the cylinder number on the side face of the big end of each connecting rod

to

prevent confusion

of

connecting rods.

5.

Remove the connecting rod cap from each piston

and rod

assembly and draw the assembly upward

from the cylinder. Take care not

to

allow the con-

necting rod

to

scratch the crankshaft pin and

cylinder. Keep the removed parts (connecting rod,

rod cap, piston etc.)

classified

by

cylinders.

6.

Remove the rings from each piston with the piston

ring

pliers.

7.

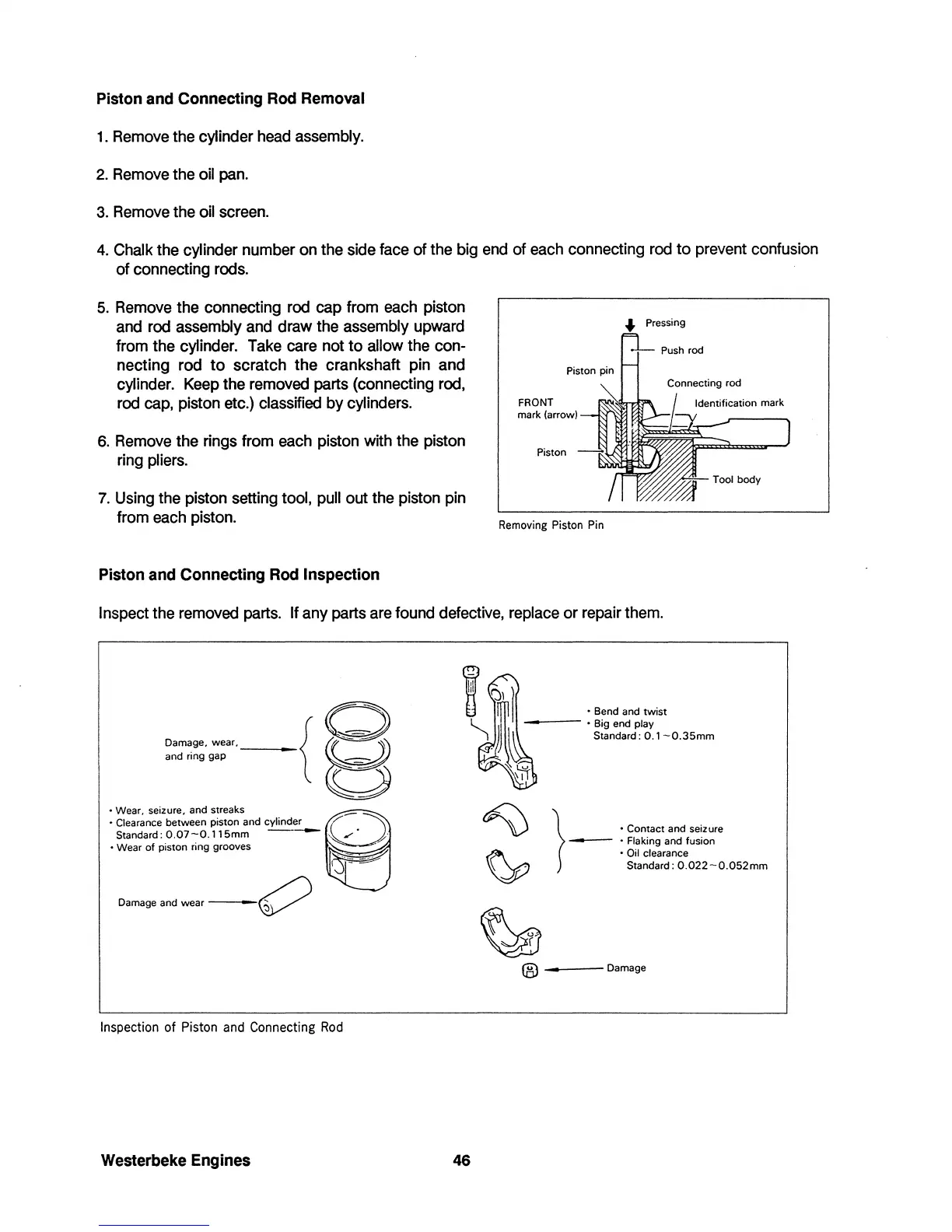

Using the piston setting tool, pull out the piston pin

from each piston.

Piston

and

Connecting

Rod

Inspection

FRONT

mark (arrow)

Piston

Removing Piston Pin

Pressing

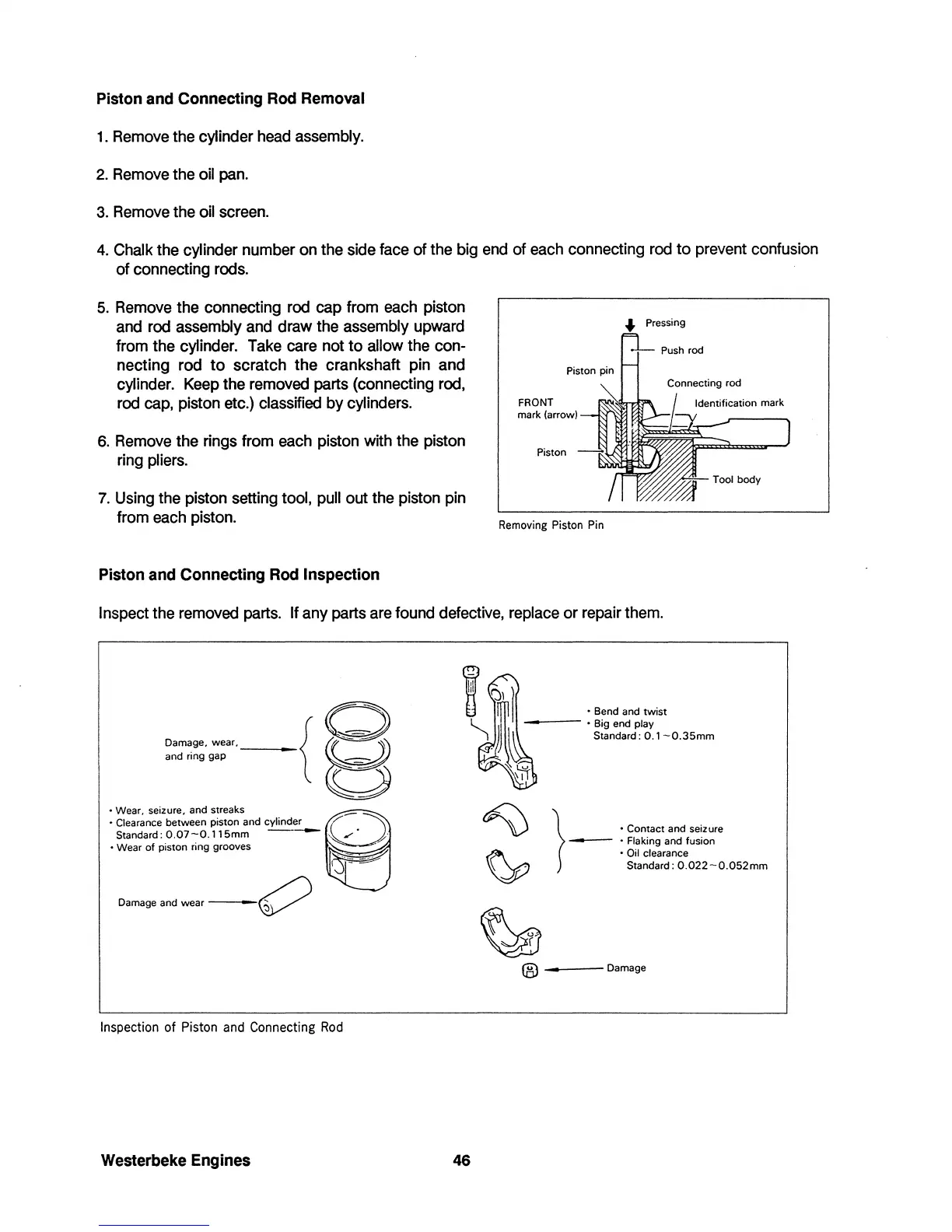

Inspect the removed parts. If any parts are found defective, replace

or

repair them.

Damage, wear,

__

{

08----::

and ring gap

~

~~

• Wear, seIzure, and streaks 8

• Clearance between piston and cylinder

tf~.

~

Standard:O.07-0.115mm

-----

~

• Wear of p,ston ring grooves

~

$

Damage

and wear

-------V

Inspection of Piston and Connecting

Rod

Westerbeke

Engines

46

• Bend and twist

---

• Big end play

Standard: 0.1

-O.35mm

}

•

Contact and seizure

-

• Flaking and fusion

• Oil clearance

Standard:

O.022-0.052mm

®

___

--

Damage

Loading...

Loading...