3.

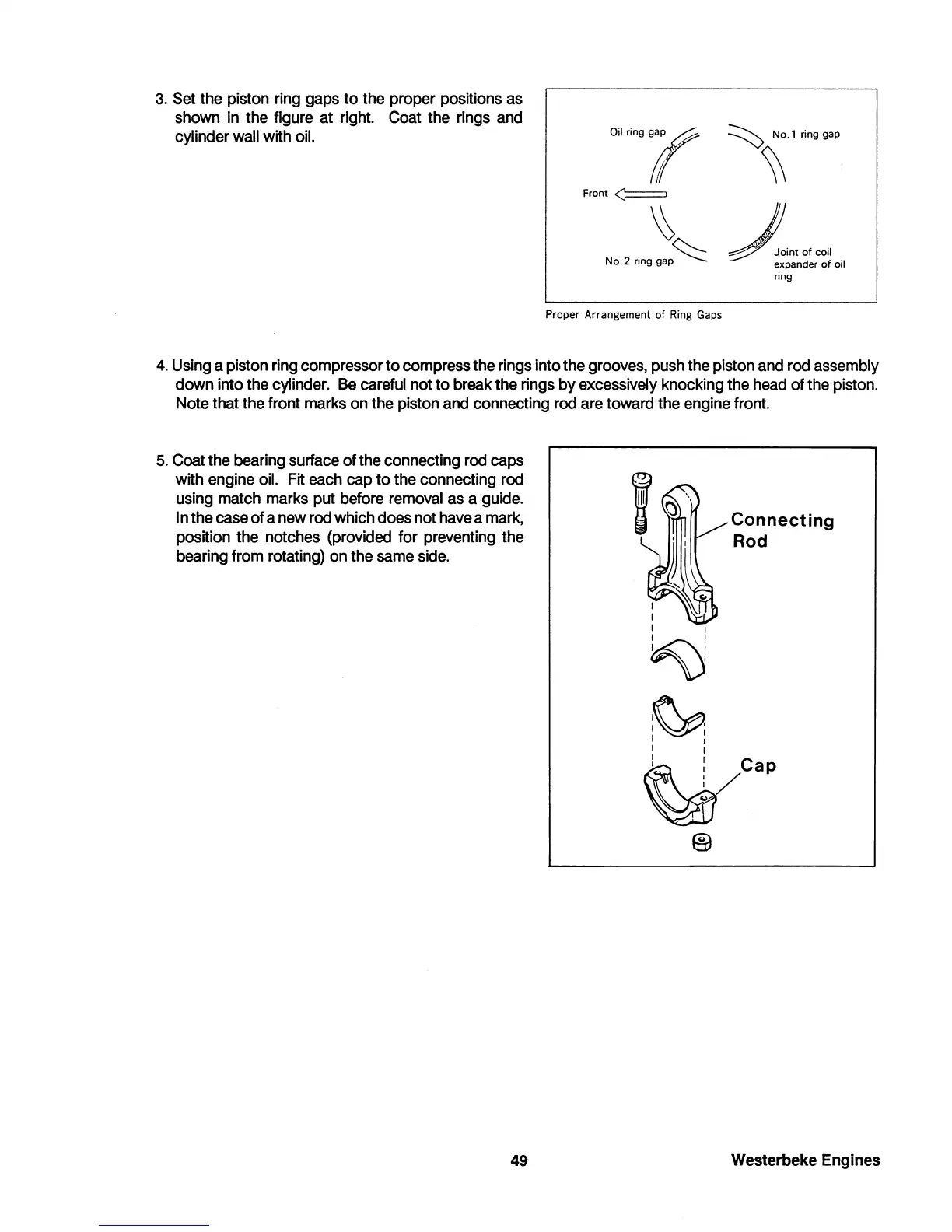

Set the piston ring gaps

to

the proper positions as

shown in the figure at right.

Coat the rings and

cylinder

wall with oil.

Ol'ri"if

Front

~

~

No.2

ring

gap~

Proper Arrangement of Ring

Gaps

~

No.1 ring gap

~

,J!."

0'

0011

expander

of

oil

ring

4. Using a piston ring compressor

to

compress the rings into the grooves, push the piston and rod assembly

down into the cylinder. Be careful not

to

break the rings

by

excessively knocking the head of the piston.

Note that the front marks on the piston and connecting rod are toward the engine front.

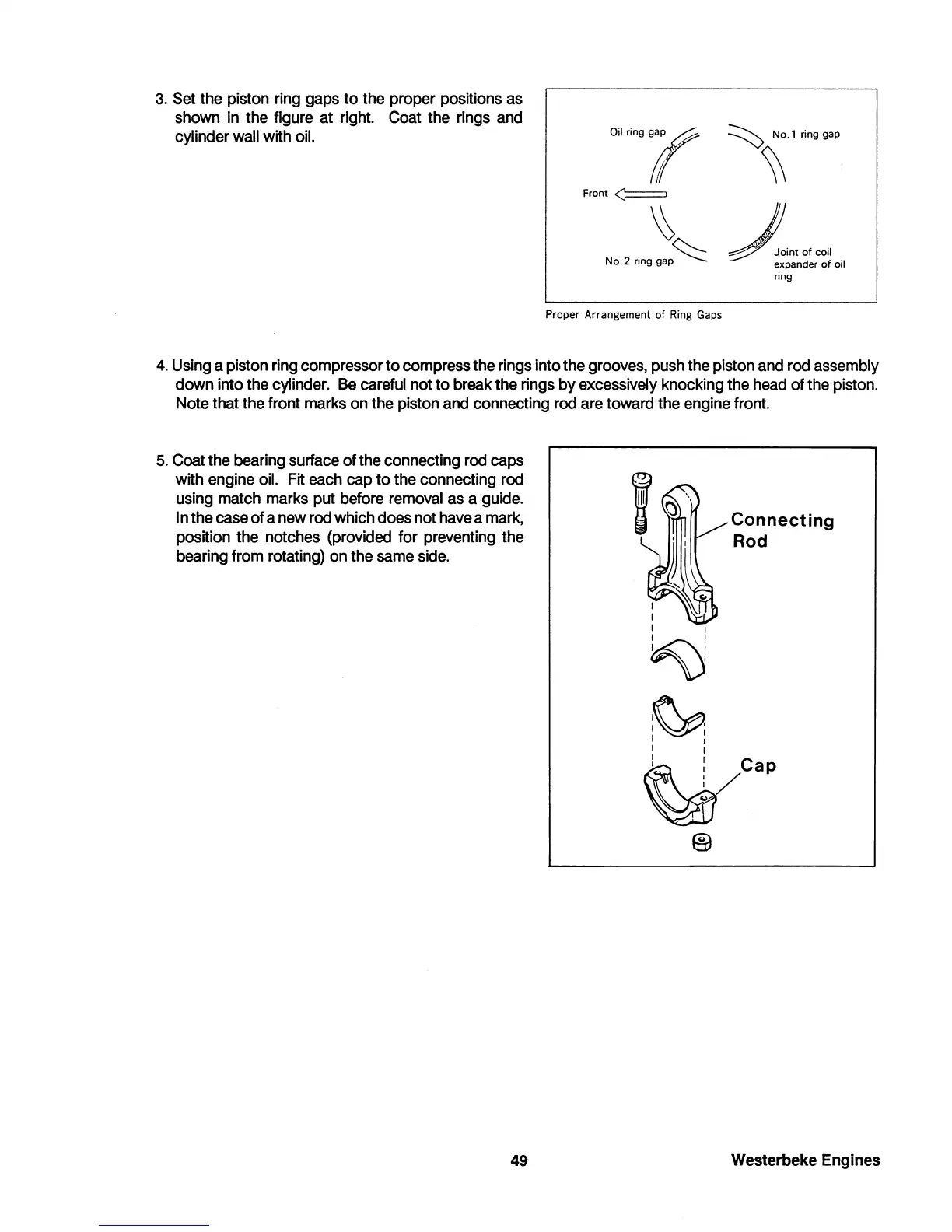

5.

Coat the bearing surface

of

the connecting rod caps

with engine oil. Fit each cap

to

the connecting rod

using match marks put before removal as a guide.

I n the case

of

a new rod which does not have a mark,

position the notches (provided for preventing the

bearing from rotating) on the same side.

49

I

I

~

:

:

I I

I

~

I I

I I

Connecting

Rod

~cap

®

Westerbeke Engines

Loading...

Loading...