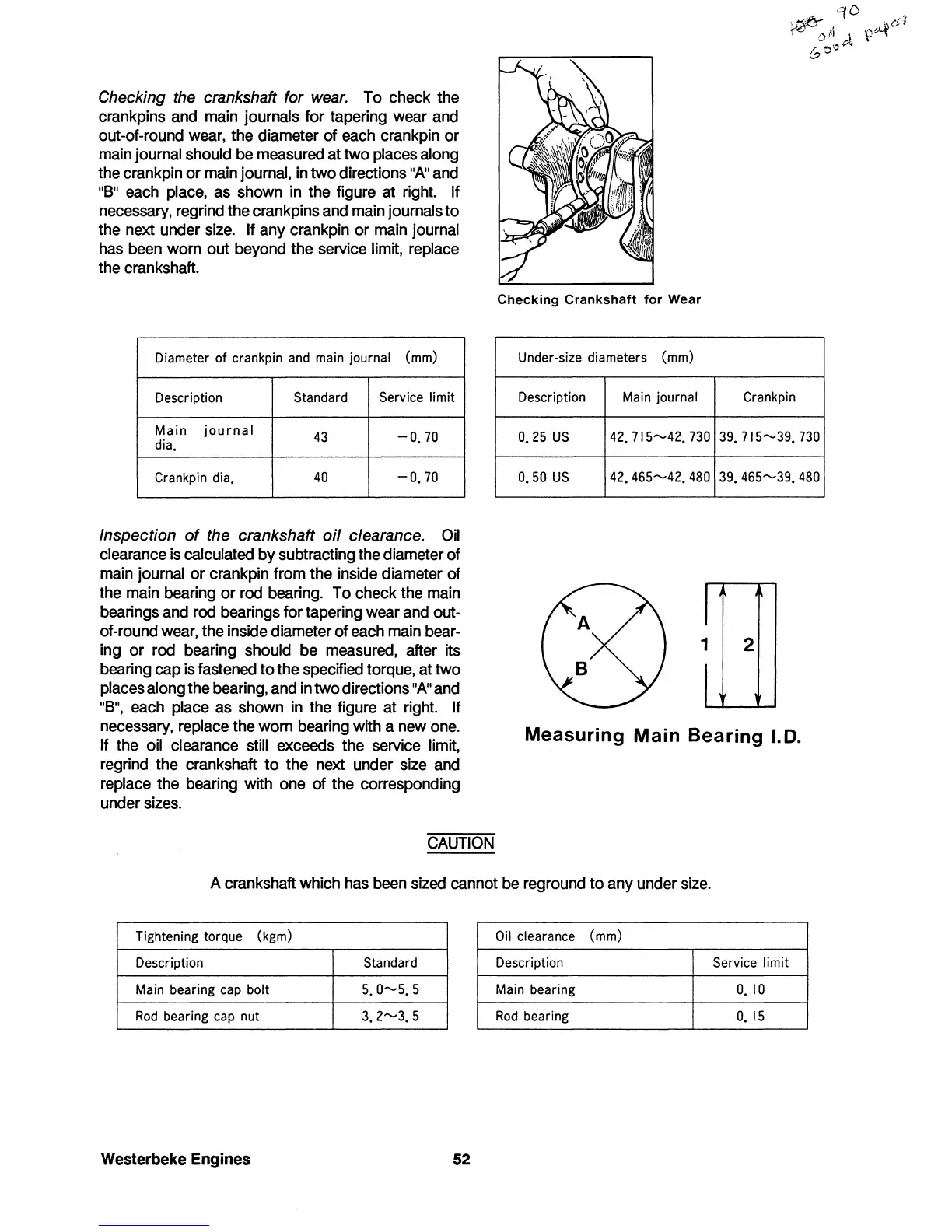

Checking

the

crankshaft for

wear.

To check the

crankpins and main journals

for

tapering wear and

out-of-round wear, the diameter

of

each crankpin

or

main journal should be measured at

two

places along

the crankpin

or

main journal, in

two

directions

"A"

and

"B"

each place, as shown in the figure at right. If

necessary, regrind the crankpins and main journals

to

the next under size.

If

any crankpin

or

main journal

has been worn out beyond the service limit, replace

the crankshaft.

Diameter of crankpin

and

main journal

(mm)

Description

Standard

Service limit

Main

journal

43

-0.70

dia.

Crankpin dia.

40

-0.70

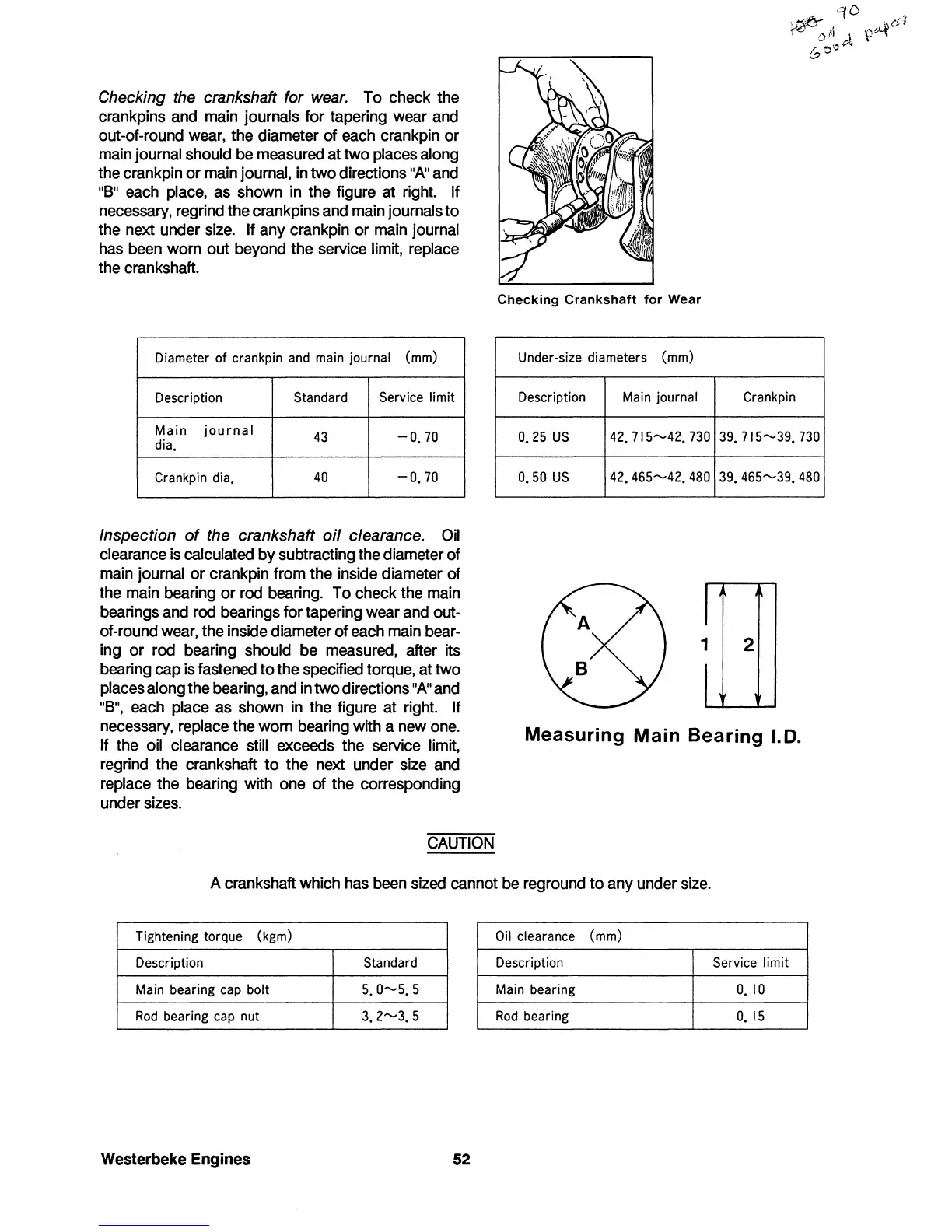

Inspection

of

the crankshaft oil clearance. Oil

clearance

is calculated

by

subtracting the diameter

of

main journal

or

crankpin from the inside diameter of

the main bearing

or

rod bearing. To check the main

bearings and rod bearings

for

tapering wear and out-

of-round wear, the inside diameter

of

each main bear-

ing

or

rod bearing should be measured, after its

bearing cap is fastened

to

the specified torque, at

two

places along the bearing, and in

two

directions

"A"

and

"B",

each place as shown in the figure at right. If

necessary, replace the worn bearing with a new one.

If the oil clearance still exceeds the service limit,

regrind the crankshaft

to

the next under size and

replace the bearing with one

of

the corresponding

under sizes.

CAUTION

Checking

Crankshaft

for

Wear

Under·size diameters

(mm)

Description Main

journal Crankpin

0.25

US

42.715""'42.730

39.

715""'39.

730

0.50

US

42.465""'42.480

39.465""'39.480

2

Measuring Main Bearing 1.0.

A crankshaft which has been sized cannot be reground

to

any under size.

Tightening torque

(kgm)

Oil

clearance

(mm)

Description

Standard Description

Service limit

Main bearing

cap

bolt

5.0""'5.5

Main bearing

0.10

Rod

bearing

cap

nut

3.2""'3.5

Rod

bearing

O.

15

Westerbeke

Engines

52

Loading...

Loading...