Injection

Nozzle

Removal

1.

Disconnect the injection pipe

and

fuel

return

pipe.

2.

Remove

the injection

nozzle

assembly from

the

cylinder

head.

CAUTION

Attach

an

identification number tag to the

removed

injection

nozzle.

Plug

the openings from

which the pipes

are

disconnected

and

the

nozzle

is

removed

to prevent intrusion of dust,

water,

and

other foreign particles into the

pipes

and

combustion

chamber.

Injection

Nozzle

Disassembly

If the

removed

nozzle

assembly

is

assumed

defective, disassemble the assembly

and

repair or replace

the

faulty

parts.

1.

Grip the

nozzle

holder body

in

a

vise.

Loosen

the retaining

nut.

Never

vise

the retaining nut to

prevent

deformation.

2.

Take

out the

shim

washer,

pressure

spring,

distance

piece,

and

nozzle

assembly.

CAUTION

Scrape

off carbon deposits with a wooden

spatula.

Keep

the

removed

parts

immersed

in

washing oil

(kerosene).

Take

special

care

not to scratch the

needle

valve

in

the

nozzle

assembly.

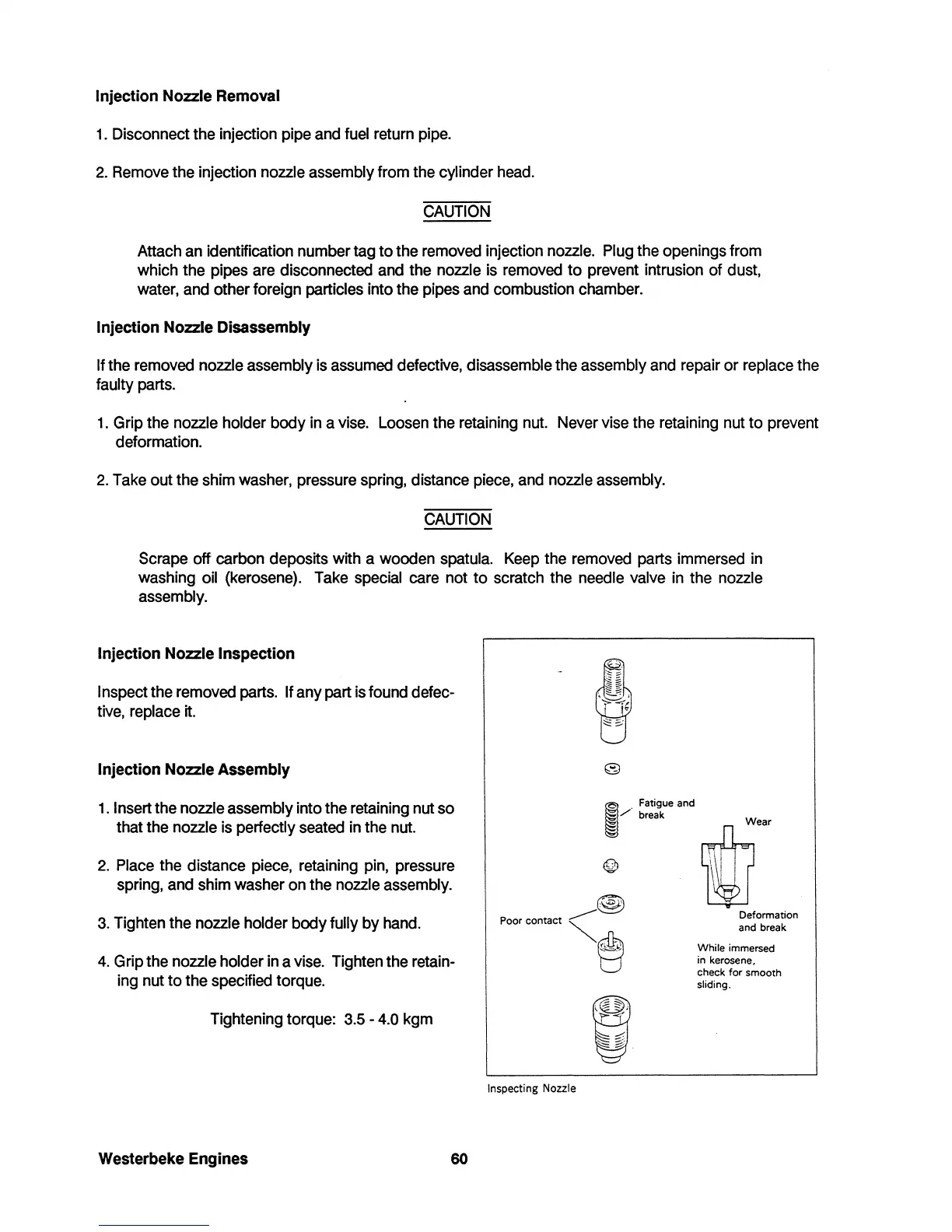

Injection

Nozzle

Inspection

Inspect the

removed

parts.

If

any part

is

found defec-

tive,

replace

it.

Injection Nozzle

Assembly

1.

Insert the

nozzle

assembly into the retaining nut

so

that the

nozzle

is

perfectly

seated

in

the

nut.

2.

Place

the distance

piece,

retaining

pin,

pressure

spring,

and

shim

washer

on

the

nozzle

assembly.

3.

Tighten the

nozzle

holder body fully by

hand.

4.

Grip

the

nozzle

holder

in

a

vise.

Tighten

the

retain-

ing

nut to the specified torque.

Tightening torque:

3.5

-

4.0

kgm

Westerbeke

Engines

60

~

. Fatigue and

!gl/ break

©

@

Poor contact

~

~

9

Inspecting Nozzle

~T

Deformation

and break

While immersed

in kerosene.

check for smooth

sliding.

Loading...

Loading...