Starter

Adjustment

and

Repair

If any abnormality is assumed

by

the following tests,

adjust the starter

or

disassemble and repair it.

1.

Pinion gap inspection.

a.

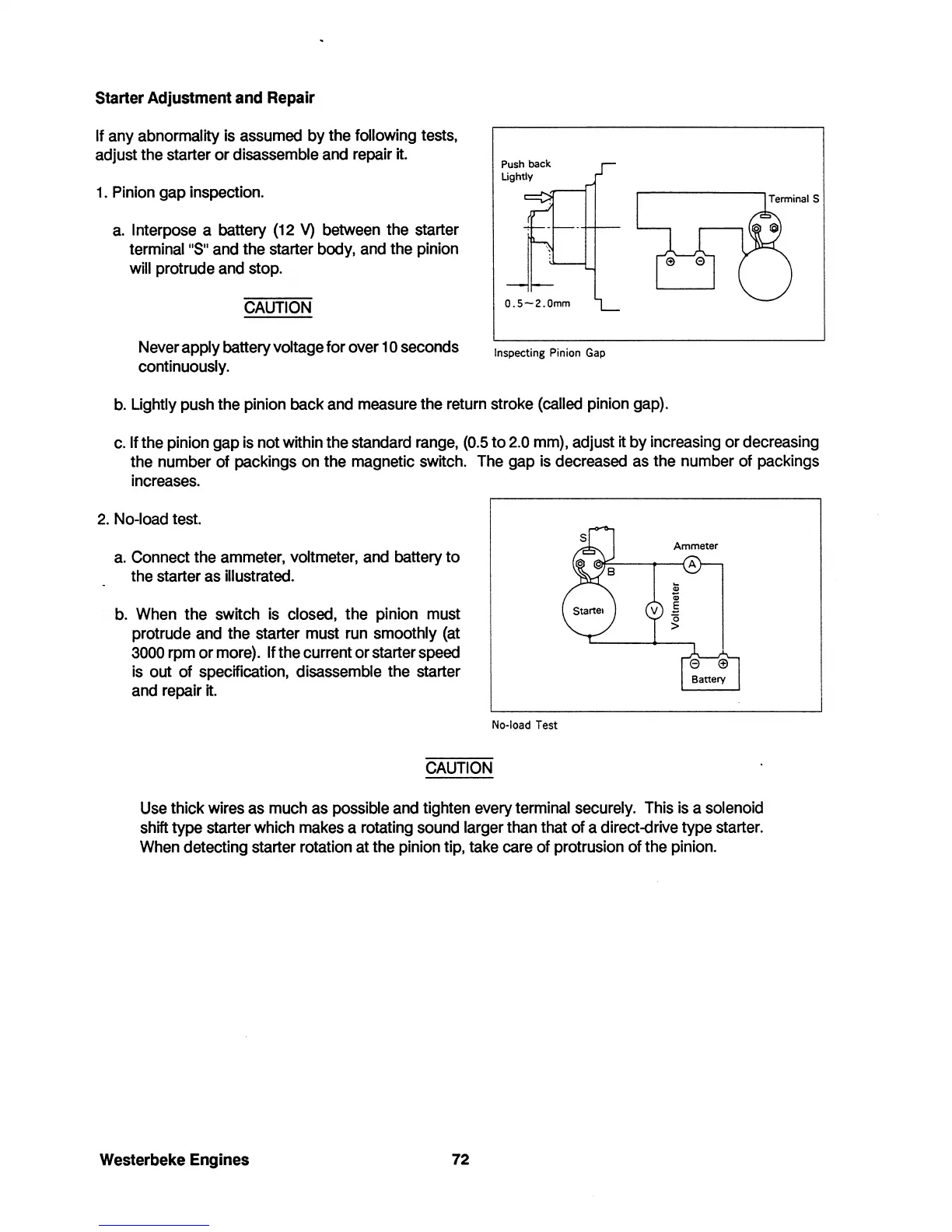

Interpose a battery (12

V)

between the starter

terminallS" and the starter body, and the pinion

will protrude and stop.

CAUTION

Never apply battery voltage

for

over 10 seconds

continuously.

Push

back

Lightly

O.5-2.0mm

Inspecting Pinion

Gap

b. Lightly push the pinion back and measure the return stroke (called pinion gap).

c.

If the pinion

gap

is

not

within the standard range, (0.5

to

2.0 mm), adjust it

by

increasing

or

decreasing

the number

of

packings on the magnetic switch. The gap is decreased as the number

of

packings

increases.

2.

No-load test.

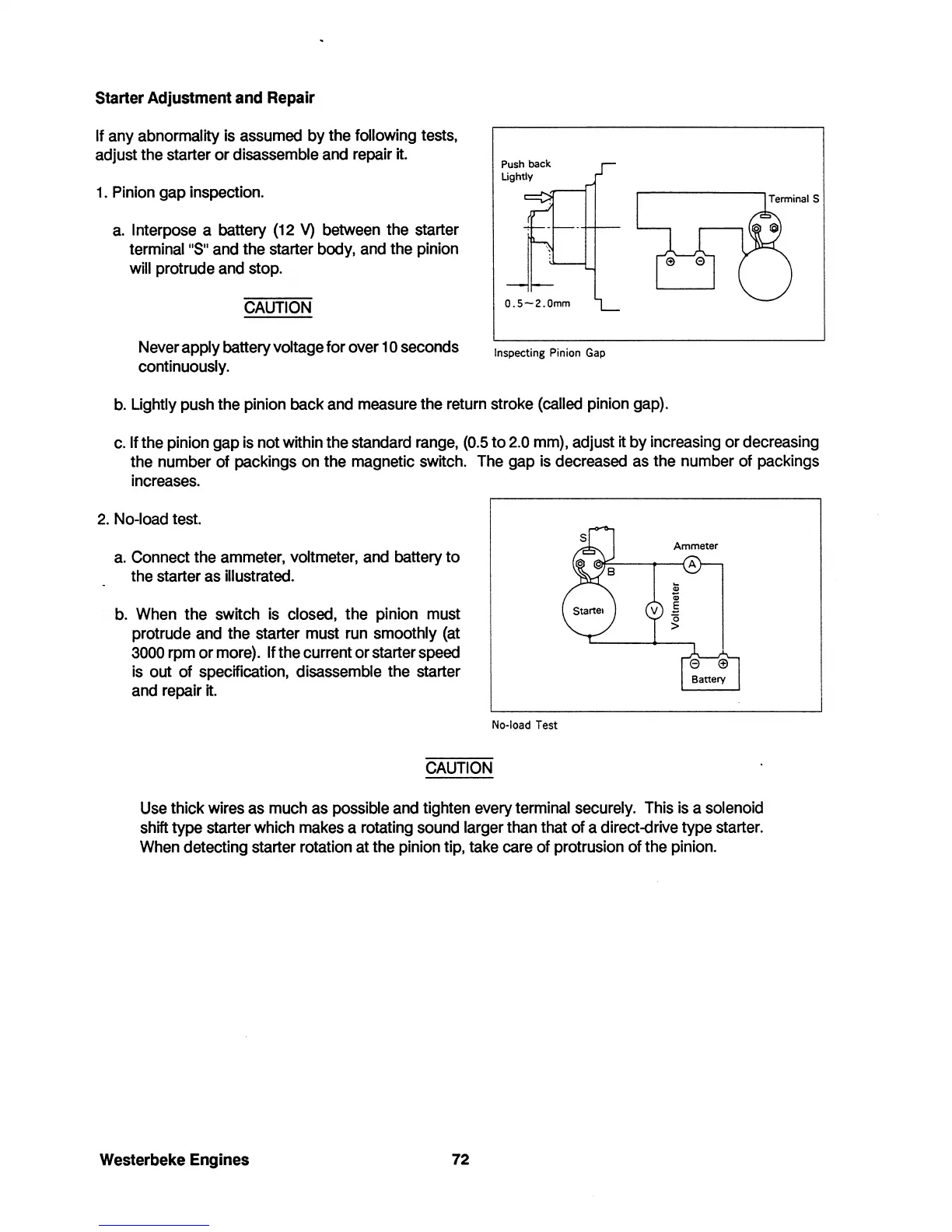

a.

Connect the ammeter, voltmeter, and battery

to

the starter as illustrated.

b. When the switch is closed, the pinion must

protrude and the starter must run smoothly (at

3000 rpm

or

more).

Ifthe

current

or

starter speed

is out

of

specification, disassemble the starter

and repair it.

CAUTION

No·load Test

Use

thick

wires as much as possible and tighten every terminal securely. This is a solenoid

shift type starter which makes a rotating sound larger than that

of

a direct-drive type starter.

When detecting starter rotation

at

the pinion tip, take care

of

protrusion

of

the pinion.

Westerbeke

Engines

72

Loading...

Loading...