2.

Inspecting the armature.

a.

Check the armature with a growler tester. If it's

short circuited, replace the armature. Also, check

for insulation between the commutator and its

shaft.

If poorly insulated, replace the armature.

b.

Measure the commutator

0.0.

and the depth of

undercut. Repair

or

replace it if the service limit

is exceeded. Also, check the commutator out-

side surface

for

dirtiness and roughness. If

rough, polish the commutator with fine-grain

sandpaper.

3.

Brush holder inspection.

a.

Check the brushes. If worn out beyond the ser-

vice limit, replace the brushes.

b.

Check the brush spring tension. If decreased

beyond the service limit, replace the springs.

c.

Check for insulation between the positive brush

holder and holder base.

If poorly insulated,

replace the holder assembly. Also, check the

brush holders for proper staking.

4.

Field coil inspection.

a.

Check for insulation between one end (brush) of

coil and yoke.

b. Check

for

conduction

between both ends

(brushes) of coil.

c.

Check the poles and coil for tightness.

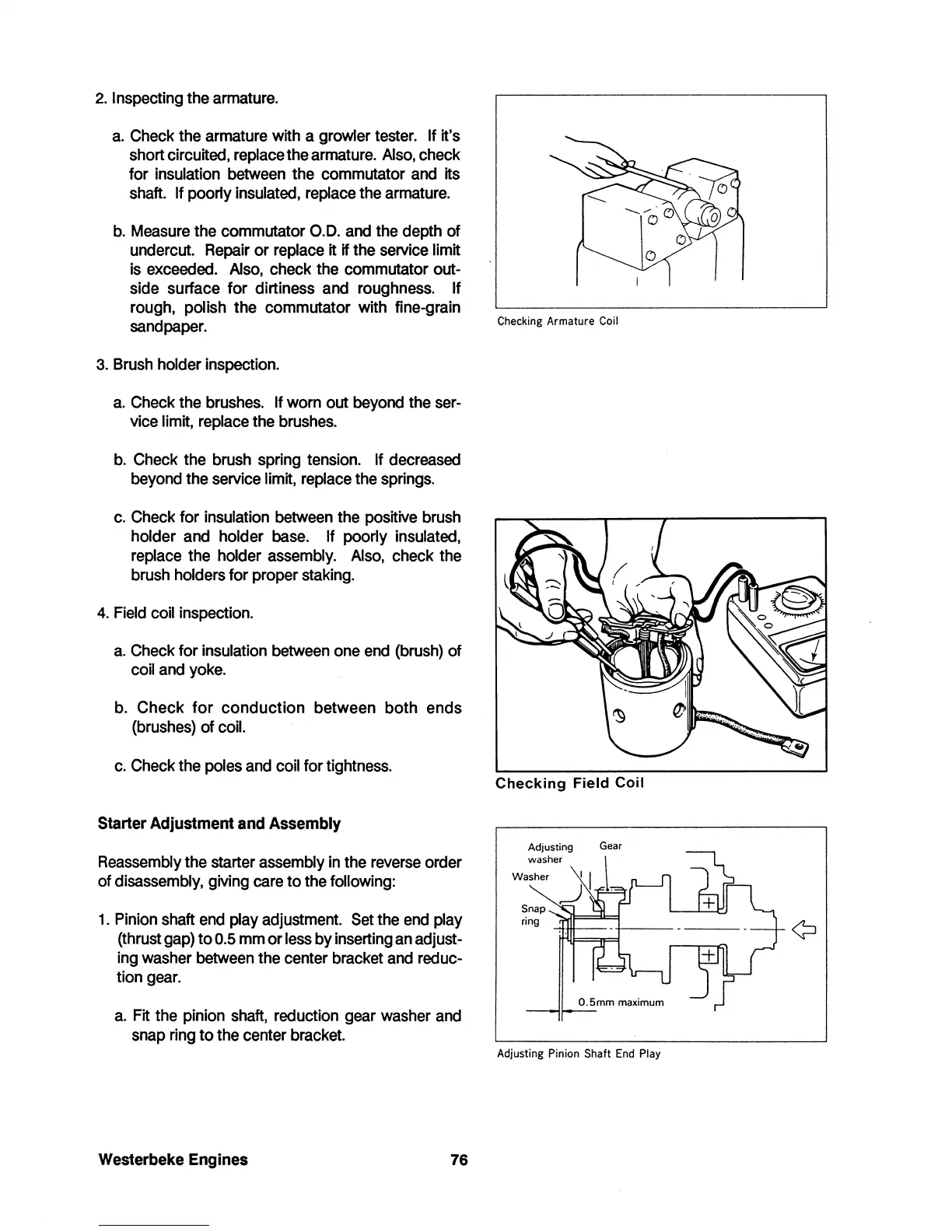

Starter Adjustment and Assembly

Reassembly the starter assembly in the reverse order

of disassembly, giving care

to

the following:

1.

Pinion shaft end play adjustment. Set the end play

(thrust gap)

to

0.5 mm

or

less by inserting an adjust-

ing washer between the center bracket and reduc-

tion gear.

a.

Fit the pinion shaft, reduction gear washer and

snap ring

to

the center bracket.

Westerbeke Engines 76

Checking Armature Coil

Checking

Field

Coil

Adjusting

Gear

washer

O.5mm maximum

--fl

..

--

Adjusting Pinion Shaft

End

Play

Loading...

Loading...