PA

GE 5

FOR SERVICE TECHNICIAN’S USE ONLY

DO NOT REMOVE OR DESTRO

Y

SOFTW

ARE VERSION DISPLAY MODE

To access Software V

ersion Display Mode, perform steps 1 and 2

of Activating the Service Diagnostic Test Modes. Toggle the cycle

selector knob until the status LEDs correspond as follows:

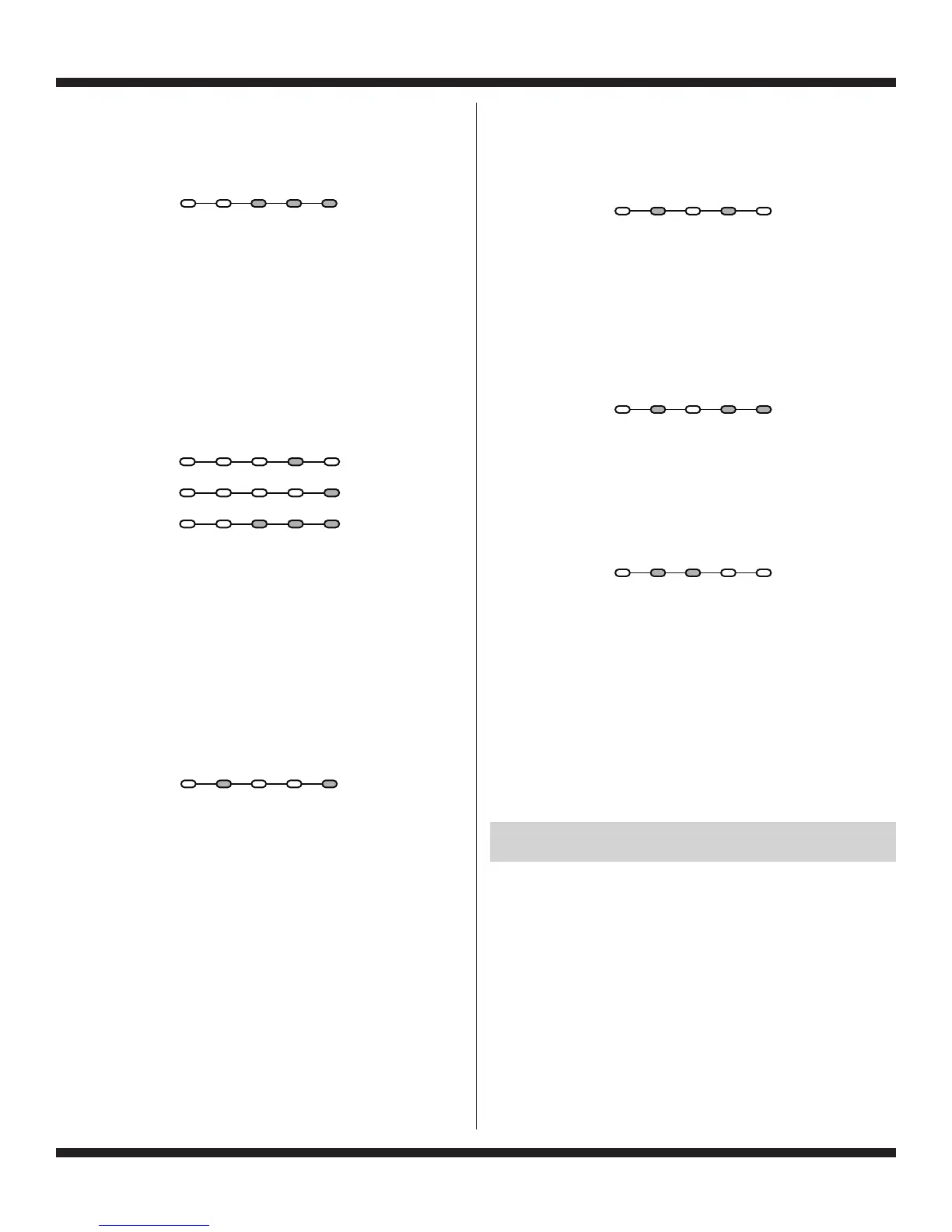

“Rinse, Final Spin, and Done” LEDs On

NOTE: Status LED names may vary between makes and models.

Press the START button to begin software display mode.

Upon entering the software version display mode, the

Major

, Minor

, and Test version numbers for the software are

displayed by alternating the state of the Status LEDs in one

second intervals; the process repeats following a pause.

To calculate the number being displayed, add the

representative numbers together that are displayed at the

same time; see chart below for representative numbers.

For example, if the s/w version is 02.01.07, the following

sequence would be displayed:

16 8 4 2 1

02

01

07

Press and hold the START button for 3 seconds at any time

to exit software version display mode.

FACTORY DIAGNOSTIC

S

This is for factory use only, as it runs the F

actory Cycle

Template for testing the washer before it leaves the factory.

TACHOMETER VERIFICA

TION MODE

To access T

achometer Verification Mode, perform steps 1 and

2 of Activating the Service Diagnostic Modes. Toggle the cycle

selector knob until the status LEDs correspond as follows:

“Soak/Wash and Done” LEDs On

NOTE: Status LED names may vary between makes and models.

Press the START button to begin tachometer verification mode.

Tachometer verification uses the status LEDs to represent

the tachometer frequency (basket RPM).

For example, slowly turn the basket by hand; as the basket

turns, the DONE

, FINAL SPIN, RINSE, and SOAK/WASH

status LEDs will illuminate one at a time in a visually repeating

cycle. The LED timing is derived from the tachometer signal

itself.

Press and hold the START button for 3 seconds at any time

to exit tachometer verification mode.

DRY FACTORY DIAGNOSTIC

S

This cycle is used by the factory to gather data for setting the

proper algorithms. This cycle is the same for all washers and

may indicate that some switches or valves are actuated that

are not used. T

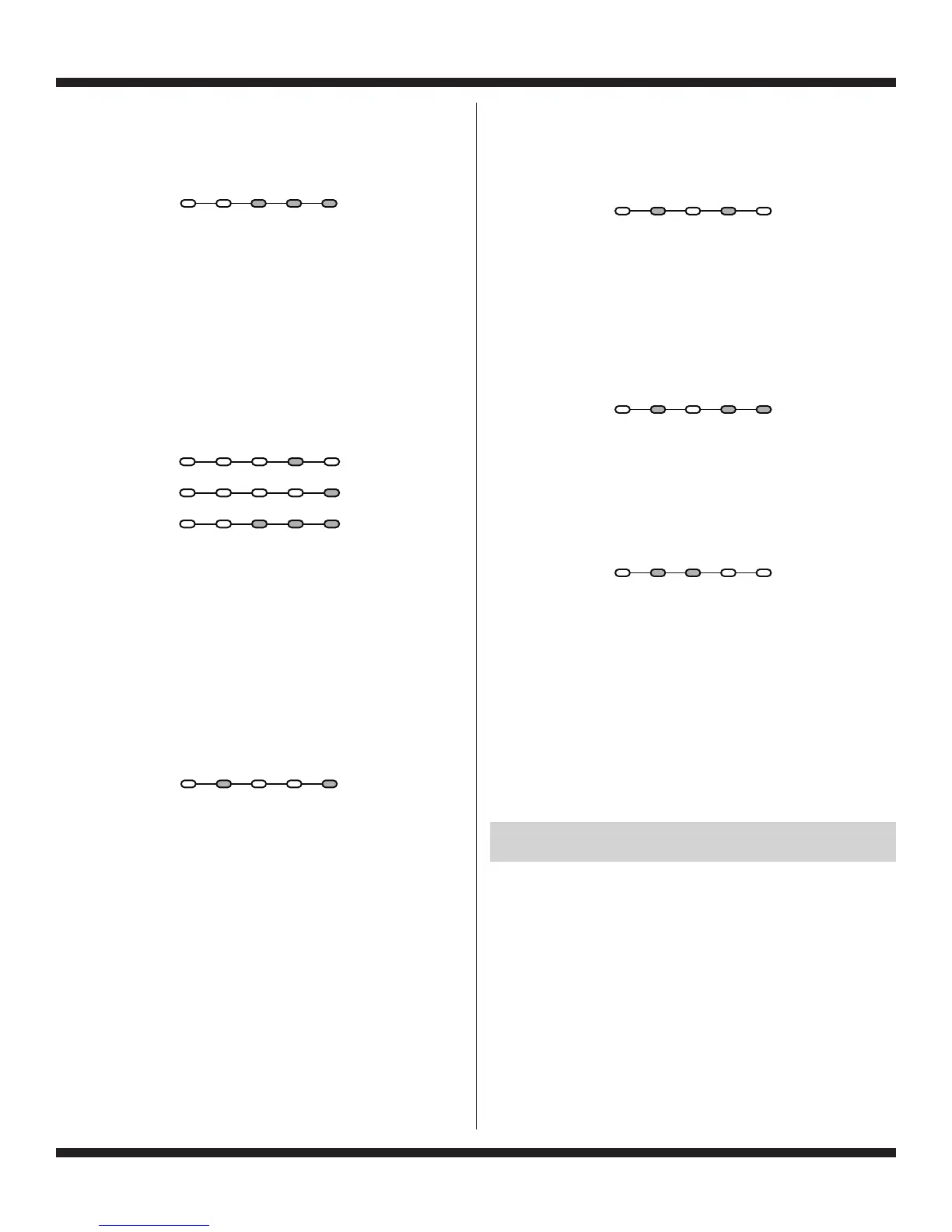

oggle the cycle selector knob until status LEDs

correspond as follows:

NOTE: This cycle should not be used as a field diagnostic test.

While running the Dry Factory cycle, the control is also

enabling the UI Diagnostics test.

FACTORY CALIBRA

TION TEST

This cycle is used by the factory to test functions and intervals

specifically for functionality testing of specific components, and

gathering data. Toggle the cycle selector knob until status LEDs

correspond as follows:

NOTE: This cycle should not be used as a field diagnostic test.

CLEAN WASHER CY

CLE

Puts washer into the W

asher Cleanout Cycle. To access the

Clean Washer Cycle, perform steps 1 and 2 of Activating the

Service Diagnostic Test Modes. Toggle the cycle selector knob

until status LEDs correspond as follows:

NOTE: This cycle should not be used with anything still loaded

in the wash basket.

CUSTOMER VIEWABLE F

AULT CODES

There are 3 fault codes that may be visible to the customer

indicated by the following Status LEDs:

SOAK/WASH LED ON (Long Fill F

ault) – Refer to “No Fill,

Long Fill” on page 7 for information.

FINAL SPIN LED ON (Long Drain F

ault) – Refer to “Long

Drain” on page 7 for information.

LID LOCKED LED FLASHING CONTINUOUSL

Y (Lid Lock

Fault) – Refer to “Lid Lock Fault” on page 6 for information.

FOR SERVICE FAULT AND ERROR CODES,

CONTINUE TO PAGES 6 AND 7

Sensing Soak/ Final

Load Wash Rinse Spin Done

Se

nsing

Soak/ Final

Load Wash Rinse Spin Done

Sensing Soak/ Final

Load Wash Rinse Spin Done

Sensing Soak/ Final

Load Wash Rinse Spin Done

Sensing Soak/ Final

Load Wash Rinse Spin Done

Sensing Soak/ Final

Load Wash Rinse Spin Done

Loading...

Loading...