Kunststoffschweißtechnik

WIDOS Einsteinstr. 5 Phone +49 (0) 71 52 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 (0) 71 52 99 39 - 40

Website: www.widos.de Email: info@widos.de

10.12.2013 Working instructions WIDOS PSM 20 Page 13 of 31

3. Functional description

All international and national process guidelines are to be basically

followed!

By using the clamping beams the plastic sheets are clamped by pneumatic cylinder and foot

valve.

Afterwards the position of the sheets are checked and if necessary changed.

Now the heating element is slewed in and the sheets are pressed on the heating element at a

defined pressure. This process is called "adjusting".

The applied power can be seen on the pressure gauge you find on the machine.

Having reached the mandatory bead height the pressure is reduced, the heating time begins.

This time is used to reach the welding temperature at the sheet ends.

After the ending of the heating-up, the tables drive apart, the heating element quickly slews

out of the machine and the tables drive together again, we call this change-over time.

The sheets are joined at the needed welding pressure and cool down under pressure

(cooling time).

The welding joint can be clamped out and the welding process is completed.

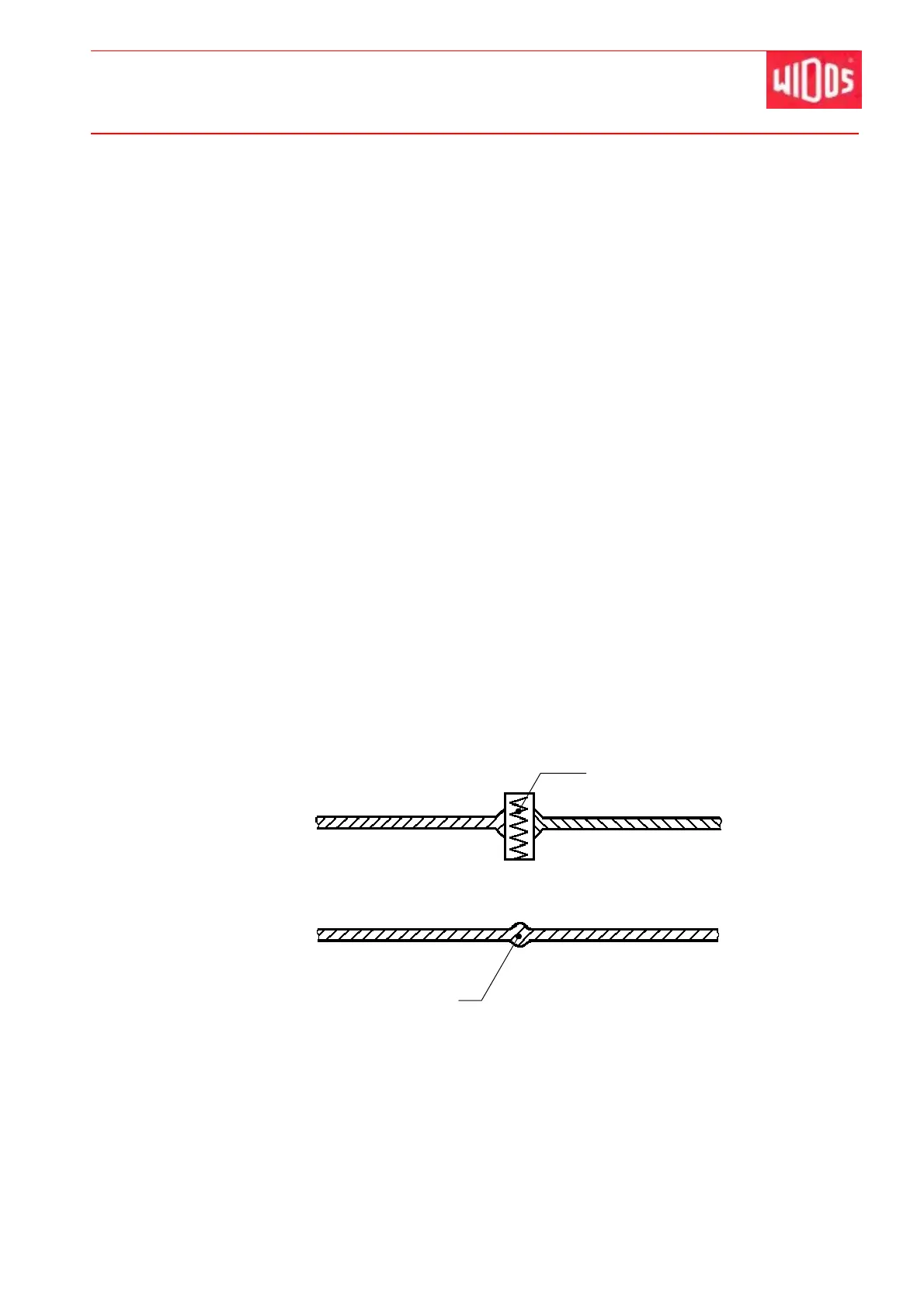

Image of a heating element butt welding:

heating element heats the

sheets up to welding

temperature

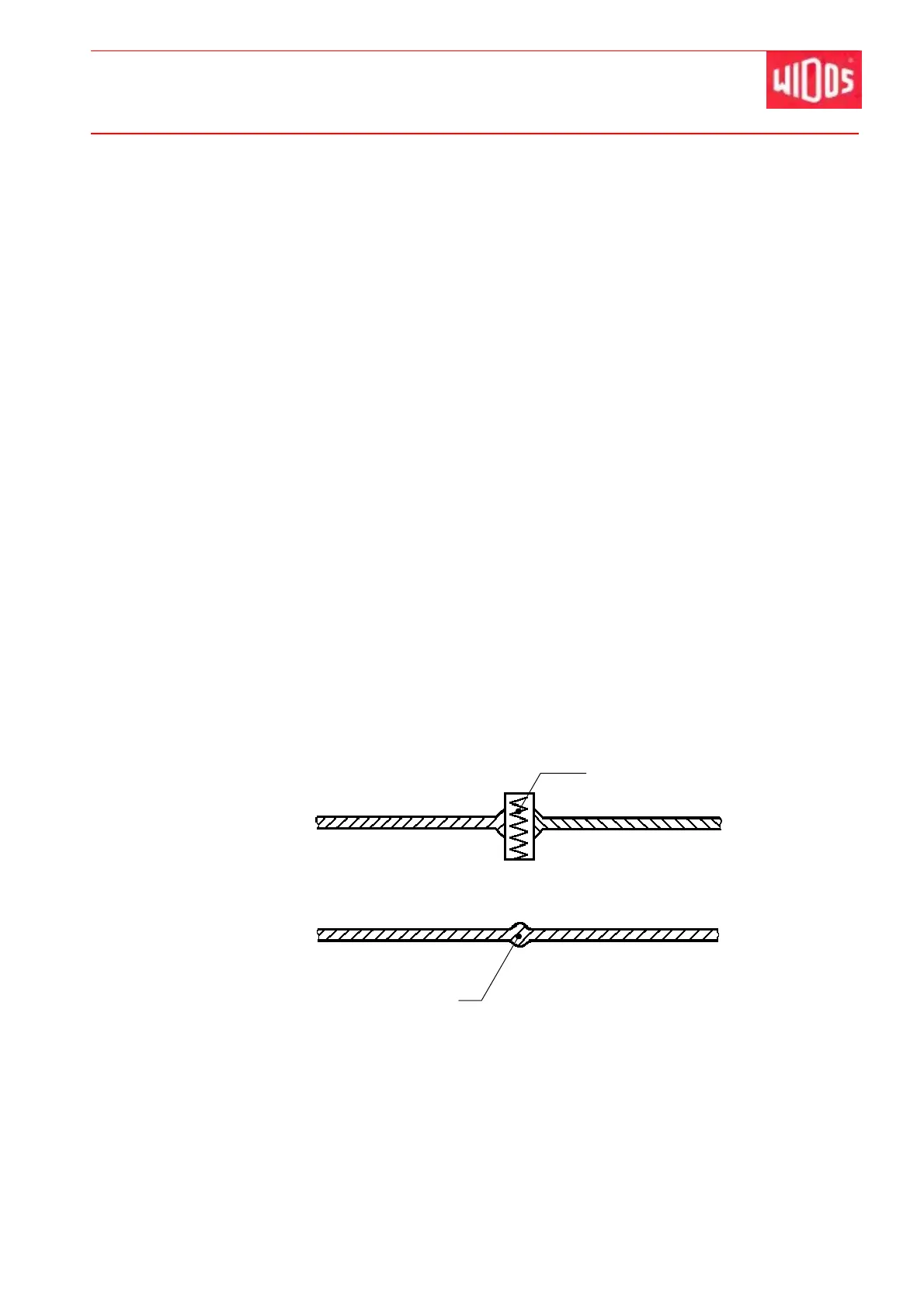

completed weld joint with

bead on top and below

Loading...

Loading...