Kunststoffschweißtechnik

Operating and indicating elements Chapter 4

10.12.2013 Working instructions WIDOS PSM 20 Page 19 of 31

4.5. How to weld a pipe out of sheets

The PSM 20 allows you to weld a plastic sheet together to get a pipe.

For this purpose clamp the plastic sheet on one side.

Now bend the sheet and fix it on the opposite side.

You may harm yourself! As soon as the tension reduces, the bent sheet will

resile into its original position.

It is recommended to secure the bent and clamped sheet additionally by

clamping belts.

After welding open both clamping beams (chapter: 4.4) and remove the welded pipe

forwards out of the machine.

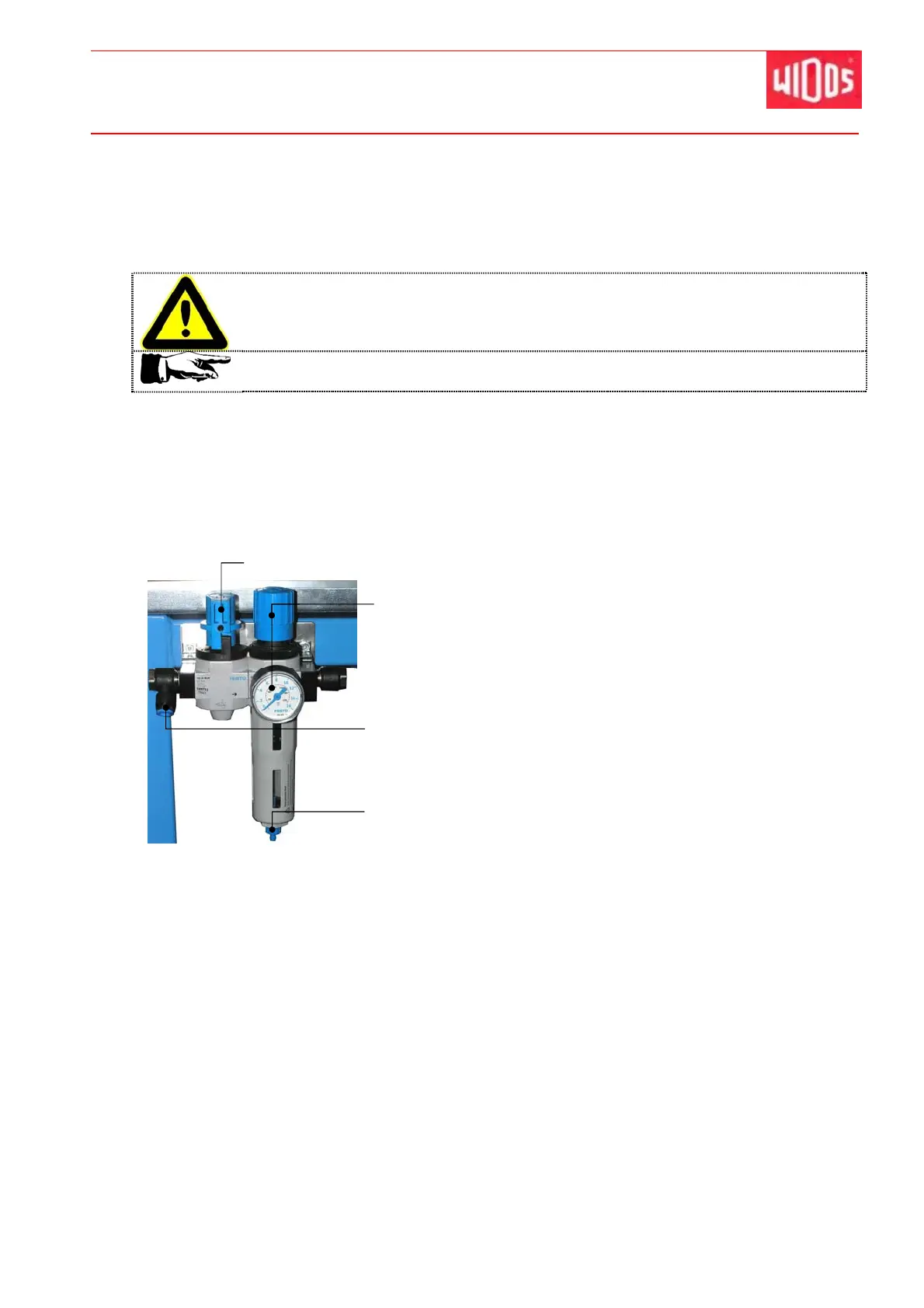

4.6. Service unit

Activate valve by turning.

The service unit (LFR-1/8-D-MINI-KC) regulates the fed compressed air onto the adjusted

working pressure and compensates pressure fluctuations. It clears the compressed air from

dirt particles and condensation water. It is not intended for the use of other media (liquids or

gases).

In order to adjust the regulator:

slowly ventilate device.

pull the pressure regulator button for the unlocking upwards (away from housing).

Turn the pressure regulator button until the desired pressure is shown on the pressure

gauge. The input pressure must be at least 1 bar larger than the output pressure.

Press the pressure regulator button downwards (towards the housing). Thereby, it is

secured against unintentional twisting.

Activating valve

Connection for compressed air hose

Manual outlet for condensation water

Pressure regulator button with pressure gauge

Loading...

Loading...